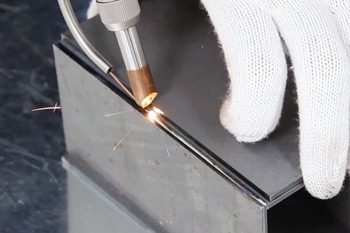

Introduction to Handheld Laser Welding Machine

Handheld Laser Welding Machines

Applications of Handheld Laser Welding Machines

Why Choose Us

Maxcool CNC is recognized as a leader in the CNC industry, setting the standard for excellence in precision engineering and manufacturing. Our commitment to innovation and quality has positioned us at the forefront of the market, enabling us to deliver advanced, high-performance machinery that meets the diverse needs of various industries. Whether you’re in automotive, aerospace, electronics, or metalworking, our CNC solutions are designed to cater to a wide range of applications, ensuring that you have the right tools to achieve optimal results.

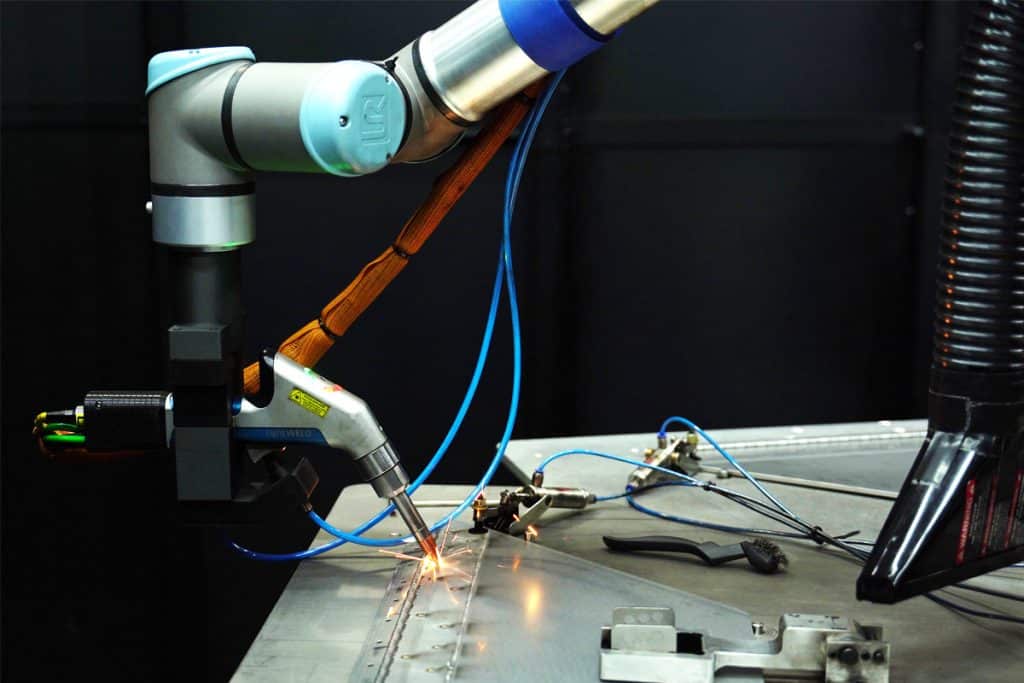

Cutting-Edge Technology

Maxcool CNC is committed to integrating the latest technological advancements into our machines. Our laser welding machines feature precise control, high efficiency, and superior performance, ensuring optimal welding results for various industrial applications.

Reliable and Durable Equipment

Our machines are built to last, with robust construction and high-quality components that guarantee long-term reliability and minimal maintenance. You can trust Maxcool CNC to provide equipment that withstands even the toughest environments.

Comprehensive Support

From pre-sales consultation to after-sales technical assistance, we are with you every step of the way. Our dedicated support team ensures you have all the information and help you need to maximize the value of your investment.

Sustainability and Efficiency

Maxcool CNC’s laser welding machines are designed with energy efficiency in mind, reducing power consumption without compromising performance. This not only lowers operational costs but also contributes to a more sustainable future.

Customer Reviews

Related Resources

Laser Welding Machine Safety Precautions

This article provides essential safety precautions for operating laser welding machines, covering key topics like PPE, maintenance, emergency procedures, and safe work environment practices.

How Does Laser Welding Achieve Deep Melting of Materials?

This article explains the physics, mechanisms, process parameters, and keyhole dynamics that enable laser welding to achieve deep melting and high-penetration welds.

How To Maintain Laser Welding Machines

This article is a comprehensive guide explaining the basic methods for maintaining a stable, efficient, and reliable laser welding machine through daily, weekly, and long-term maintenance.