Introduction to Laser Cutting Machines

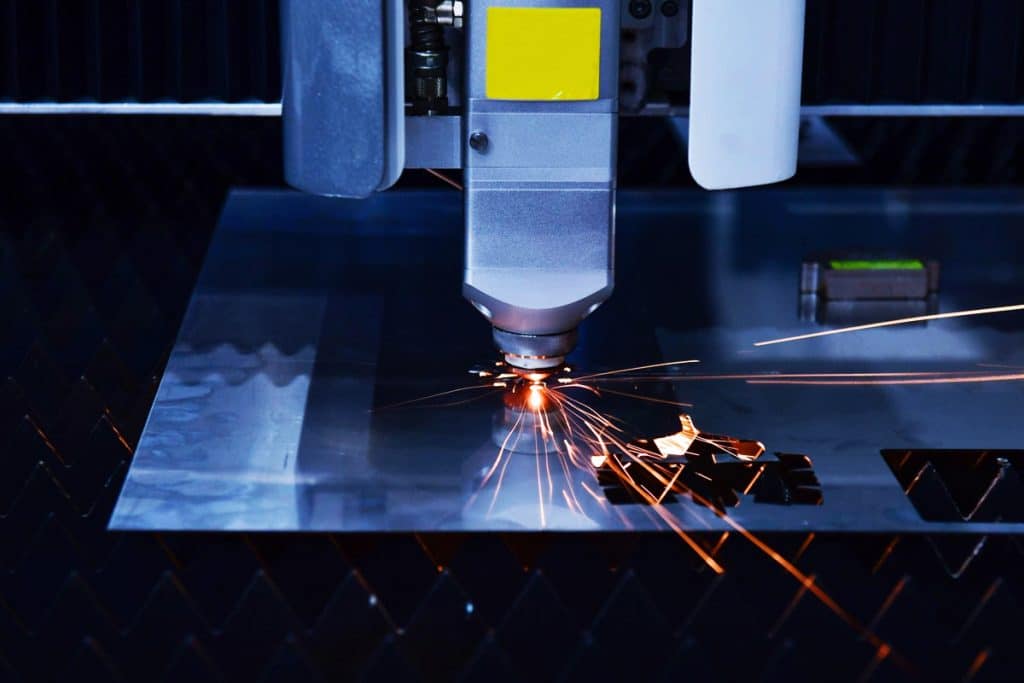

Laser cutting machines are the gold standard for precision metal cutting. Powered by solid-state fiber lasers, these machines deliver clean, accurate cuts at high speed, with minimal maintenance and maximum energy efficiency. Whether you’re cutting stainless steel, carbon steel, aluminum, brass, or copper, lasers outperform traditional CO2 systems in both quality and cost-effectiveness. What sets laser cutting machines apart is their ability to concentrate high-power laser beams through a fiber-optic cable, producing an incredibly fine and focused cutting point. This means faster processing, tighter tolerances, and reduced material waste. For industries like automotive, aerospace, fabrication, and electronics, lasers are now the go-to solution for high-volume production and intricate part designs.

Modern laser cutting machines come in a range of sizes and power ratings, from compact units for small shops to high-power systems built for industrial-scale output. They support automation features like loading/unloading systems, CNC controls, and smart software integration—making them ideal for streamlined workflows and Industry 4.0 environments. Whether you’re upgrading your production line or starting a new operation, investing in a laser cutting machine means lower running costs, higher precision, and long-term reliability.

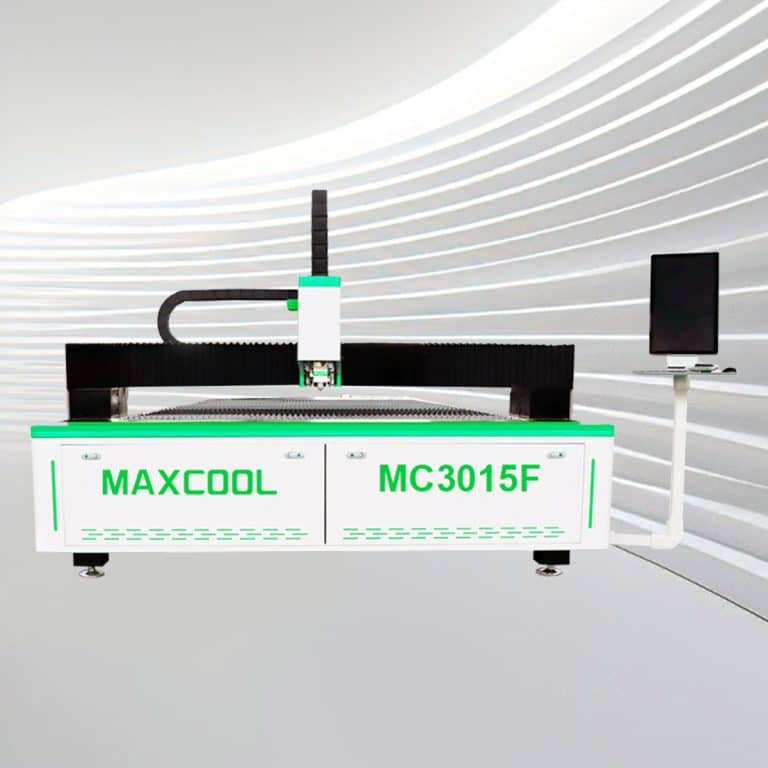

Laser Cutting Machines

Laser cutting machines are engineered for fast, precise, and efficient cutting of metal materials. Unlike older CO2 systems, fiber lasers use a solid-state laser source delivered through a fiber-optic cable. This technology offers higher cutting speeds, lower operating costs, and minimal maintenance—all while delivering exceptional edge quality. These machines excel at cutting a wide range of metals, including stainless steel, carbon steel, aluminum, copper, and brass. Their high energy efficiency and ability to handle reflective materials make them the preferred choice for industries like automotive, aerospace, metal fabrication, and electronics.

Available in a variety of power levels and cutting bed sizes, laser cutting machines can be scaled to suit small shops or high-volume industrial operations. Many models come equipped with automation-ready features, intelligent controls, and real-time monitoring systems—helping reduce labor, minimize errors, and boost productivity. If you need fast turnaround, high precision, and consistent results, laser cutting machines deliver.

Comparison of Different Types of Laser Cutting Machines

| Feature | Sheet Laser Cutting Machine | Tube Laser Cutting Machine | Sheet & Tube Laser Cutting Machine |

|---|---|---|---|

| Cutting Capability | Flat metal sheets only | Round, square, and rectangular tubes only | Both flat sheets and tubes |

| Material Types | Steel, stainless steel, aluminum, etc. | Same as sheet (for tubes only) | Full range of flat and tubular metals |

| Cutting Axes | 2 or 3-axis (X, Y, Z) | 3 to 5-axis with rotary | 5-axis with rotary and flat support |

| Precision | High accuracy for flat parts | High accuracy for tube profiles | Consistent accuracy on both formats |

| Speed | Optimized for sheet cutting | Optimized for tube cutting | Slightly slower than dedicated machines |

| Versatility | Limited to sheet parts | Limited to tubular structures | Highly versatile for mixed production |

| Footprint | Compact | Medium to large | Largest due to dual function |

| Automation Options | Auto loading/unloading for sheets | Auto tube feeding and support | Both sheet and tube automation |

| Software | Sheet nesting and layout tools | Tube nesting, angle cut, hole positioning | Integrated for both types |

| Setup Complexity | Straightforward | Moderate (requires tube alignment) | Most complex due to dual-mode system |

| Operator Skill Level | Basic to intermediate | Intermediate | Intermediate to advanced |

| Initial Investment | Lowest cost | Mid-range cost | Highest due to combined capabilities |

| Running Cost | Low maintenance | Moderate maintenance | Higher due to additional components |

| Ideal Use Case | Panels, enclosures, brackets | Frames, piping, structural components | Mixed production environments |

| Industries Served | Sheet metal fabrication, signage | Furniture, automotive frames, construction | Automotive, manufacturing, job shops |

Applications of Laser Cutting Machines

Laser cutting machines are used across a wide range of industries where speed, accuracy, and clean edge quality are essential. Designed to handle metal materials like stainless steel, carbon steel, aluminum, brass, and copper, lasers are the go-to solution for high-precision parts and high-volume production. In automotive manufacturing, lasers are used to cut body panels, brackets, exhaust parts, and structural components. In aerospace, they’re trusted for cutting lightweight metal parts with exacting tolerances. Sheet metal fabrication shops rely on lasers for rapid prototyping and full-scale production of enclosures, cabinets, signage, and architectural elements.

Electronics and electrical equipment manufacturers use lasers for cutting enclosures, chassis, and heat sinks with fine detail and minimal distortion. In furniture and appliance industries, they’re used to cut both flat and tubular metal components, allowing for fast, clean assembly. Thanks to their ability to integrate with automation systems and handle complex geometries, laser cutting machines are also ideal for custom fabrication, metal job shops, and industrial production lines. Whether you’re cutting thousands of identical parts or a variety of custom shapes, laser technology offers the performance, consistency, and flexibility modern manufacturing demands.

Customer Reviews

Our fiber laser cutting machine has drastically reduced our cutting time and increased output. The precision is top-notch, even on complex parts. We’ve cut down on post-processing and scrap material. It’s reliable, easy to operate, and well worth the investment for any high-volume metal shop.

MichaelProduction Manager

As a small business, we needed equipment that delivers quality and consistency. Our fiber laser has exceeded expectations—fast cuts, clean edges, and almost no maintenance issues. It’s been a key asset in growing our shop’s capabilities and reputation. We’re thrilled with the results.

SarahOwner

We replaced our CO2 laser cutting machine with a fiber laser and immediately noticed the difference. Cutting speed, energy efficiency, and edge quality are all significantly better. It’s allowed us to expand into new materials and improve lead times. This machine has paid for itself faster than expected.

DavidOperations Director

Our team loves working with the new fiber laser cutting system. It’s intuitive, powerful, and accurate. The software makes programming simple, and the auto-loading feature helps us save time on each job. We’ve seen a big bump in productivity since installation.

LisaFabrication Lead

We use our fiber laser every day for a wide range of parts, and it hasn’t let us down. The cut quality is clean and consistent across various metals. Uptime has been excellent, and support was responsive when we had questions. Great addition to our production line.

AnthonyShop Supervisor

Related Resources

Understanding the Operating Costs of Laser Cutting Machines

This article explores the operating cost drivers of laser cutting machines, including electricity, auxiliary gas, consumables, labor, maintenance, downtime, and how to accurately calculate the cost of each part.

What Factors Affect Laser Cutting Speed

This article explores the key factors that influence laser cutting speed, including material properties, laser power, beam parameters, assist gas, and machine setup, providing insights for optimization.

Laser Cutting VS Flame Cutting

This article provides a comprehensive comparison of laser cutting and flame cutting, covering the principles, capabilities, advantages, limitations, and ideal applications of each method.

Frequently Asked Questions

What Materials Can Laser Cutting Machines Cut?

Fiber laser cutting machines are designed primarily for metal processing. They can cut stainless steel, carbon steel, mild steel, aluminum, brass, copper, galvanized steel, and titanium. Thanks to the fiber laser’s high beam intensity and short wavelength (typically around 1.06 microns), it excels at cutting reflective and conductive materials—where other laser types, like CO2, often struggle. However, fiber lasers are not suitable for cutting non-metals like wood, plastics, or glass.

How do Fiber Lasers Differ from CO2 Lasers?

The main difference lies in the laser source and how the beam is delivered. Fiber lasers use a solid-state source and deliver the beam through flexible fiber optics, making them more compact and energy-efficient. CO2 lasers use gas mixtures and mirrors, requiring more maintenance and energy. Fiber lasers offer higher cutting speeds, especially on thin to medium metals, and require less frequent calibration. They also have a longer operational lifespan—often exceeding 100,000 hours—and are much better at cutting reflective metals like aluminum and copper.

What Thickness Can Lasers Cut?

Cutting thickness depends on the power of the machine. Lower-power fiber lasers (1kW–2kW) can cut up to 6mm stainless steel or 10mm mild steel. Mid-range models (3kW–6kW) handle up to 16–20mm in steel. High-power units (10kW–20kW) can cut 30mm or more with excellent edge quality. Keep in mind, maximum thickness is also influenced by cutting speed, assist gas (oxygen, nitrogen, or air), and material purity.

Are Laser Cutting Machines Suitable For Tube Cutting?

Yes, but not all models. Dedicated tube laser cutting machines are designed specifically for round, square, rectangular, and custom-profile tubes. They use rotary axes and advanced clamping systems to rotate and stabilize the tubes during cutting. Alternatively, combo machines (Sheet & Tube) offer dual functionality, allowing users to switch between flat sheet cutting and tube cutting in a single system—ideal for job shops and manufacturers who handle varied projects.

How Accurate Are Laser Cutting Machines?

Fiber lasers are known for their exceptional precision. Tolerances typically range from ±0.05mm to ±0.1mm depending on the machine’s design, material type, and thickness. They also maintain consistency across high-speed production. The laser beam’s fine focus and controlled heat zone allow for intricate cuts with sharp edges and minimal distortion, even on thin materials. Accuracy is further enhanced when paired with CNC controls and real-time feedback systems.

What Kind of Maintenance is Required?

Compared to CO2 systems, fiber lasers require significantly less maintenance. No mirrors to align, no resonator gases, and fewer moving parts. Routine maintenance includes:

- Cleaning the protective lens and nozzles

- Checking and topping off coolant in the chiller

- Inspecting fiber cables and connections

- Updating firmware and monitoring diagnostics

Can Lasers Be Integrated with Automation?

Absolutely. Many modern laser cutting machines support full automation, including automatic sheet loading/unloading systems, robotic arms, conveyor systems, and smart sorting units. Advanced models come with integrated CNC controllers, nesting software for material optimization, real-time diagnostics, and remote monitoring capabilities. These features drastically improve production efficiency, reduce downtime, and lower labor costs—making fiber lasers a perfect fit for Industry 4.0 environments.

How do I Choose The Right Laser Cutting Machine?

Start by identifying your production needs. Consider:

- Material type & thickness: Know your most commonly used materials and their max thickness.

- Production volume: Higher output may justify automation and higher power.

- Part complexity: Intricate designs benefit from machines with tighter tolerances and advanced software.

- Space and layout: Ensure your shop can accommodate the machine’s footprint, especially with tube-cutting models.

- Future growth: Consider whether you’ll expand into new materials or part types later.

Get Laser Cutting Solutions

Unlock the power of precision and efficiency with Maxcool CNC’s laser cutting solutions. Our state-of-the-art machines are engineered to deliver flawless cuts across a wide range of materials, from stainless steels to carbon steels. Whether you’re working on intricate designs, large-scale production, or complex shapes, our advanced laser technology ensures exceptional quality and speed. With customizable options, expert support, and a commitment to innovation, Maxcool CNC is your trusted partner for all your laser cutting needs. Take your manufacturing to the next level—get in touch today and experience cutting-edge solutions designed to elevate your business.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser cutting. Our team will promptly reach out to discuss your unique requirements and guide you through the journey of enhancing your manufacturing capabilities with Maxcool CNC’s laser cutting solutions.