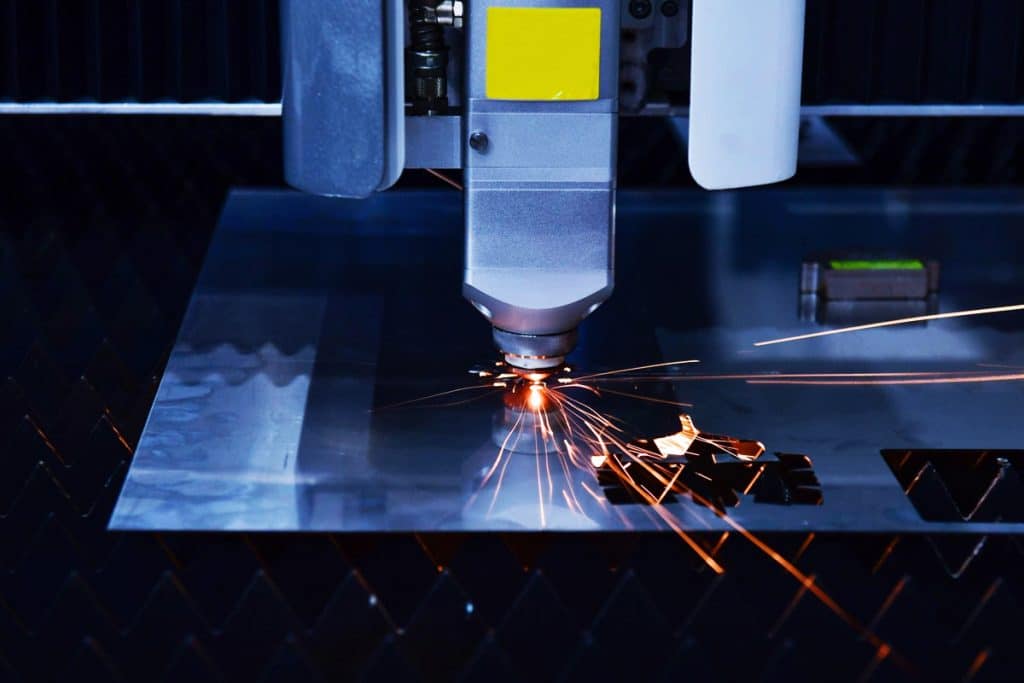

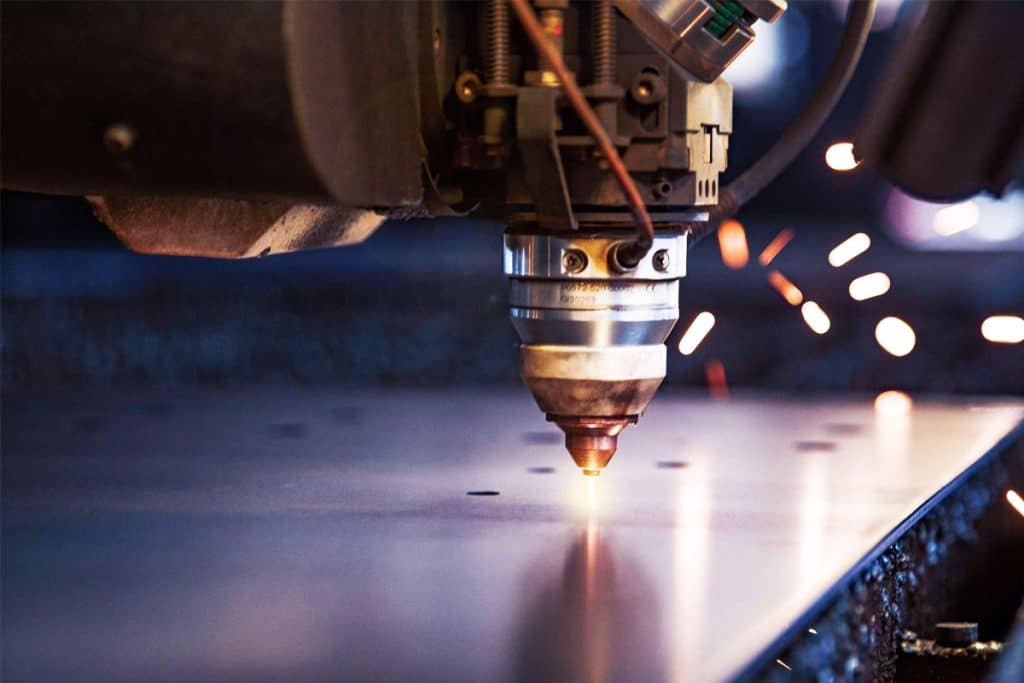

Understanding the Operating Costs of Laser Cutting Machines

This article explores the operating cost drivers of laser cutting machines, including electricity, auxiliary gas, consumables, labor, maintenance, downtime, and how to accurately calculate the cost of each part.

Laser Welding Machine Safety Precautions

This article provides essential safety precautions for operating laser welding machines, covering key topics like PPE, maintenance, emergency procedures, and safe work environment practices.

What Factors Should Be Considered When Selecting Laser Cleaning Machines

This article explores the key factors to consider when selecting laser cleaning machines, including technical specifications, industry needs, safety, cost, and support requirements for optimal performance.

What Factors Affect Laser Cutting Speed

This article explores the key factors that influence laser cutting speed, including material properties, laser power, beam parameters, assist gas, and machine setup, providing insights for optimization.

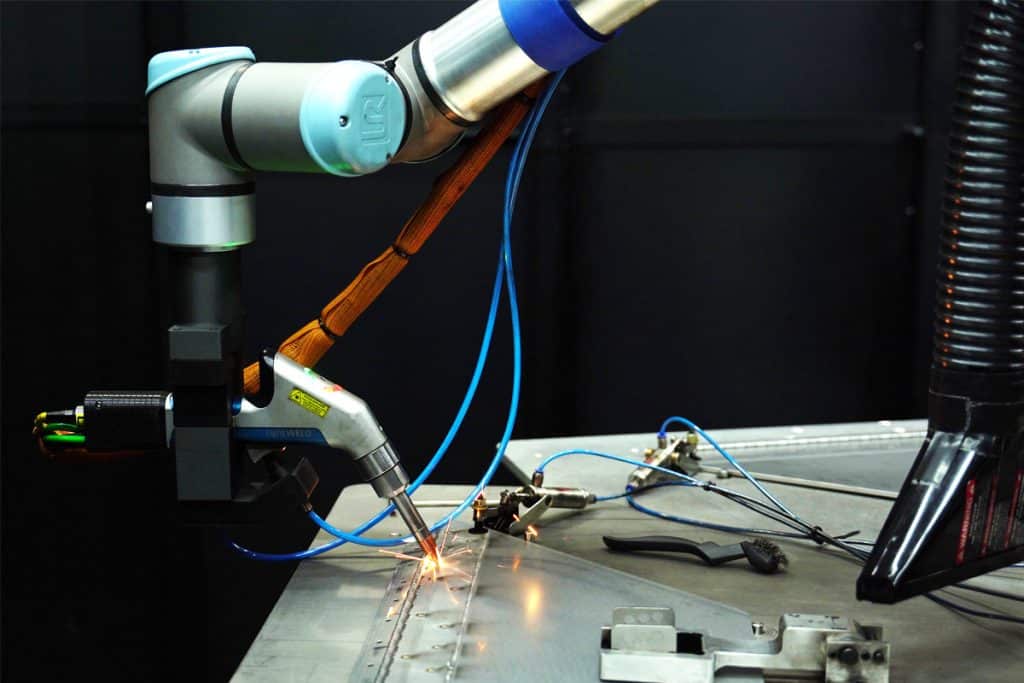

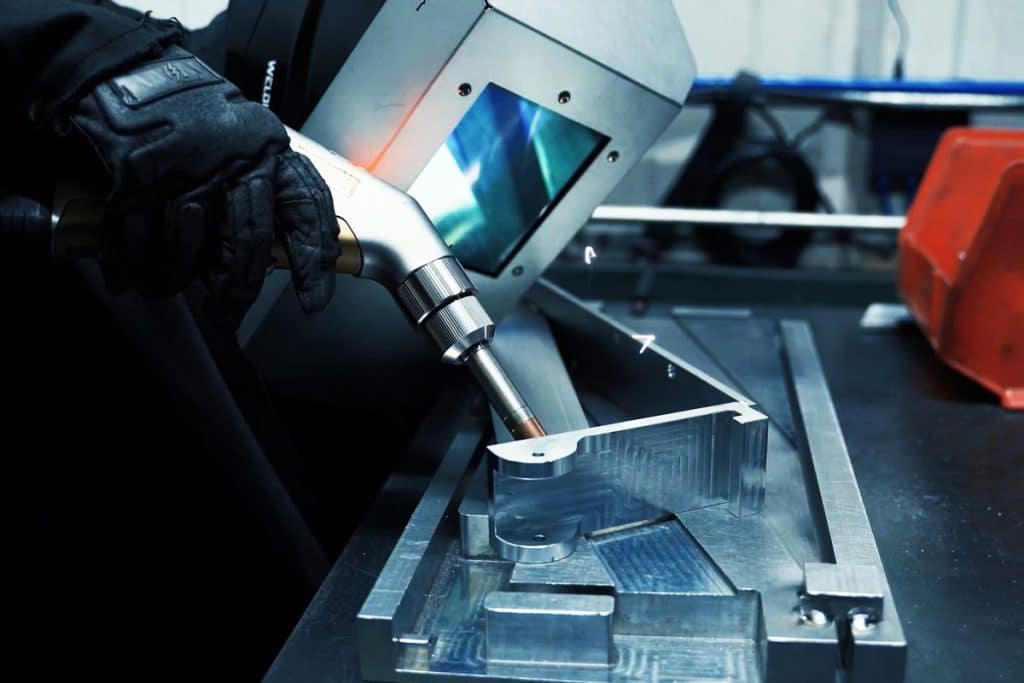

How Does Laser Welding Achieve Deep Melting of Materials?

This article explains the physics, mechanisms, process parameters, and keyhole dynamics that enable laser welding to achieve deep melting and high-penetration welds.

Laser Cutting VS Flame Cutting

This article provides a comprehensive comparison of laser cutting and flame cutting, covering the principles, capabilities, advantages, limitations, and ideal applications of each method.

How To Maintain Laser Welding Machines

This article is a comprehensive guide explaining the basic methods for maintaining a stable, efficient, and reliable laser welding machine through daily, weekly, and long-term maintenance.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article provides a comprehensive overview of common challenges in fiber laser cutting, their causes, and practical solutions for improving cutting quality, stability, and production efficiency.

Power Requirements For Laser Welding Machines

This article explains the electrical power requirements of fiber laser welding machines, covering energy consumption, efficiency, cooling systems, and installation planning.

Does Laser Cutting Use Gases?

This article aims to explore the application of gases in laser cutting, their role in precision and efficiency, and how different gases affect cutting quality, cost, and performance.

What Precautions Should Be Taken When Laser Welding?

This article is a comprehensive guide outlining the necessary safety measures, equipment considerations, and best practices to ensure safe and efficient laser welding operations.

Laser Cleaning Machine Cooling System Maintenance Guide

Comprehensive guide on maintaining laser cleaning machine cooling systems, covering inspection, coolant care, troubleshooting, and best practices for reliable performance and longevity.