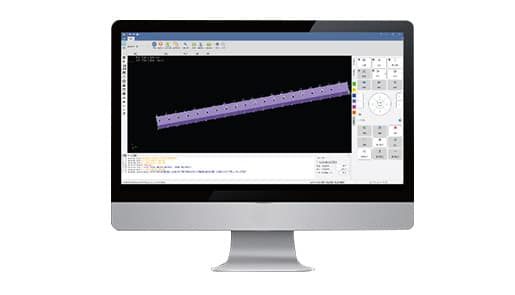

Professional Tube Fiber Laser Cutting Machine

The professional tube fiber laser cutting machine is designed for precise and efficient cutting of metal tubes and pipes, offering high-speed, high-accuracy performance with minimal material waste.

4 reviews for Professional Tube Fiber Laser Cutting Machine

Bethany –

We moved many jobs to the tube laser. Speed is great, edges are smooth, and repeat cuts match drawings without constant tweaks or rework.

Aaron Cole –

Cuts round and square tubes fast with clean edges. Setup is simple, auto-loading works well, and accuracy on holes and slots is spot on.

Carlos –

Handles thick and thin tubes without fuss. Bevel cuts are accurate, notches fit first try, and the machine saves us hours on each batch.

Diana –

Easy to program, stable cutting on long tubes, and very little burr. Hole positions line up perfectly with assemblies, reducing fit issues in production.