Introduction to Tube Laser Cutting Machines

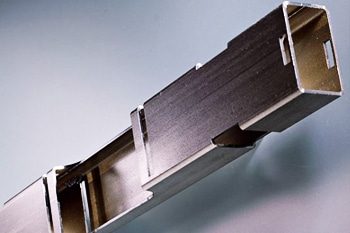

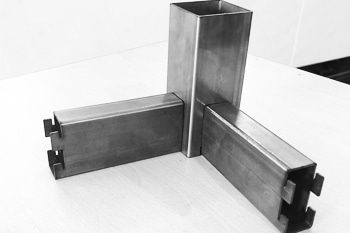

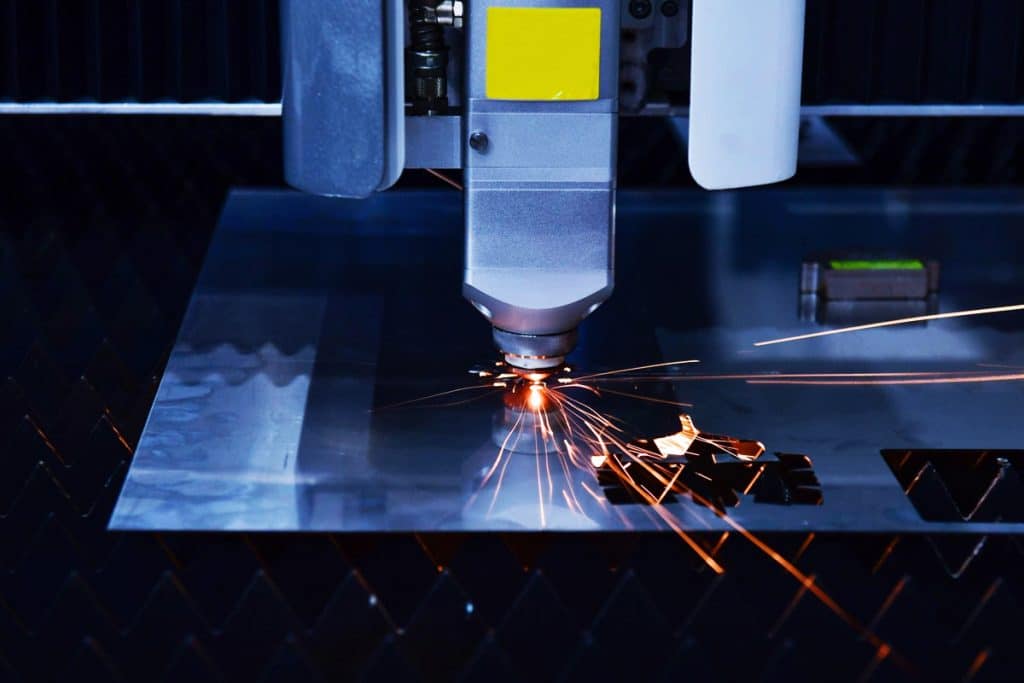

Tube laser cutting machines are advanced manufacturing systems designed specifically for processing tubular materials, including round, square, rectangular, and irregular profiles. Powered by fiber laser technology, these machines deliver high-speed, precision cutting with exceptional edge quality, making them an essential tool for modern metal fabrication. Traditional cutting methods, such as sawing, drilling, or milling, require multiple steps and often leave rough finishes that necessitate secondary processing. Tube laser cutting machines eliminate these inefficiencies by combining cutting, piercing, and contouring into a single automated operation. With the help of CNC controls and rotary chucks, the machine securely positions and rotates the tube while the laser beam performs intricate cuts, holes, slots, miters, and even bevels with consistent accuracy.

Fiber laser sources give these machines a clear advantage. They are highly efficient, consume less power compared to CO2 laser cutting systems, and handle reflective metals such as aluminum, brass, and copper with ease. The result is faster processing, lower operating costs, and reduced downtime thanks to minimal maintenance requirements. Industries such as automotive, aerospace, construction, furniture, and agricultural equipment rely heavily on tube structures, making tube laser cutting machines indispensable for manufacturers looking to streamline production. They not only increase output and precision but also unlock greater design flexibility by enabling complex geometries that are difficult or impossible with conventional tools. By integrating speed, accuracy, and versatility, tube laser cutting machines represent a smarter, more cost-effective solution for modern fabrication needs.

Tube Laser Cutting Machines

Tube laser cutting machines are specialized fiber laser cutting systems designed for processing round, square, rectangular, and irregular-shaped tubes with precision and efficiency. Unlike traditional methods such as sawing or drilling, fiber laser technology allows for fast, contactless cutting with clean edges and minimal post-processing. Equipped with rotary chucks and advanced CNC controls, these machines rotate and position tubes while the laser beam executes highly accurate cuts, slots, miters, and contours. This capability makes them ideal for industries such as automotive, construction, aerospace, and furniture manufacturing, where tubular structures are widely used.

Fiber lasers excel at cutting stainless steel, carbon steel, aluminum, brass, and copper tubing, even at varying thicknesses. Their energy efficiency, low maintenance, and long service life provide significant cost savings compared to other cutting methods. By combining speed, precision, and flexibility, tube laser cutting machines help manufacturers improve productivity, reduce material waste, and expand design possibilities—all with a single, reliable system.

Applications of Tube Laser Cutting Machines

Tube laser cutting machines are widely used in industries where tubular components form the backbone of structures and products. Their ability to process round, square, rectangular, and irregular-shaped tubes with high precision makes them indispensable for modern manufacturing. In the automotive sector, these machines produce exhaust pipes, chassis elements, and safety components with consistent accuracy, improving both performance and reliability. The construction and architecture industries use tube lasers for railings, support beams, frameworks, and decorative structures, where both strength and design detail are important.

Furniture and appliance manufacturers rely on them for tubular frames, chair legs, shelving, and durable yet aesthetically refined designs. In aerospace, precision-cut tubing is essential for lightweight but strong structural parts. The agricultural and heavy machinery sectors benefit from tube lasers to produce rugged equipment parts and reinforced tubular assemblies that withstand demanding conditions. Because fiber lasers cut stainless steel, carbon steel, aluminum, brass, and copper with clean edges and minimal waste, they eliminate secondary finishing steps. This not only saves time and labor but also allows manufacturers to experiment with more complex geometries, offering greater design flexibility. From mass production to custom fabrication, tube laser cutting machines deliver the accuracy, speed, and efficiency needed to stay competitive.

Customer Reviews

The tube laser cutting machine has completely transformed our production line. We now process different tube shapes with ease, and the edge quality is so clean that we no longer need grinding or finishing. Setup is quick, downtime is minimal, and throughput has increased dramatically. For us, this machine has been a real game-changer and has paid for itself in just a few months.

DanielProduction Manager

In aerospace, precision is everything. This tube laser cutting machine has allowed us to produce parts with extremely tight tolerances and consistent results. Once challenging and even complex geometries are now completed in one step. The machine’s ability to cut stainless steel and aluminum tubing flawlessly has shortened our lead times and given us a serious competitive edge in the market.

ElenaOperations Director

As a job shop serving multiple industries, flexibility is key. This tube laser machine has allowed us to take on projects that were previously impossible with traditional methods. We can switch between different tube sizes quickly, handle high production volumes, and still maintain accuracy. Customers notice the difference in turnaround and quality, and we’ve seen a significant boost in repeat orders since adding it.

MichaelCEO

We manufacture structural frameworks, and the tube laser cutting machine has streamlined our workflow beyond expectations. What used to take hours of manual labor is now done in minutes with perfect precision. The machine reduces material waste, cuts costs, and helps us deliver projects on time. It has improved our efficiency so much that we are planning to add a second unit soon.

SarahFabrication Supervisor

Agricultural machinery requires strong, durable tubular parts, and this machine handles them with ease. Thick-walled tubes that used to wear down our older machines are cut smoothly and consistently. The automation features make it simple for operators to run long batches, and the laser source requires very little maintenance. It has improved both our productivity and the quality of our finished equipment.

AhmedTechnical Manager

Related Resources

Understanding the Operating Costs of Laser Cutting Machines

This article explores the operating cost drivers of laser cutting machines, including electricity, auxiliary gas, consumables, labor, maintenance, downtime, and how to accurately calculate the cost of each part.

What Factors Affect Laser Cutting Speed

This article explores the key factors that influence laser cutting speed, including material properties, laser power, beam parameters, assist gas, and machine setup, providing insights for optimization.

Laser Cutting VS Flame Cutting

This article provides a comprehensive comparison of laser cutting and flame cutting, covering the principles, capabilities, advantages, limitations, and ideal applications of each method.

Frequently Asked Questions

What Are Tube Laser Cutting Machines?

A tube laser cutting machine is an advanced CNC system designed specifically for processing tubular materials. Unlike flatbed laser cutters that focus on sheet metal, tube laser cutters are equipped with rotary chucks that clamp and rotate tubes while the fiber laser beam cuts with extreme precision. They can handle round, square, rectangular, oval, and even custom-profile tubes. The fiber laser source generates a concentrated beam of light through fiber optics, delivering stable cutting power, fast processing speeds, and low operating costs. These machines are widely adopted because they combine precision, automation, and versatility, making them essential for industries that rely on tubular frameworks and components.

What Materials Can Tube Laser Cutting Machines Process?

Tube laser cutting machines can process a wide variety of metals, including:

- Stainless Steel: for corrosion-resistant applications like railings, furniture, and aerospace parts.

- Carbon Steel: widely used for automotive frames, construction components, and heavy machinery.

- Aluminum & Alloys: ideal for lightweight but strong parts in transportation and aerospace.

- Brass & Copper: commonly used in decorative applications, HVAC, and electronics.

How Accurate Are Tube Laser Cutting Machines?

These machines deliver exceptional precision, typically achieving tolerances within ±0.05 mm depending on the material thickness and machine configuration. Advanced CNC controls enable the precise cutting of complex shapes—such as slots, holes, miters, and bevels—to be repeated with the same accuracy, even across large production runs. The high beam quality of fiber lasers ensures narrow kerf widths, clean edges, and minimal heat-affected zones, reducing material distortion. This level of accuracy not only reduces waste but also eliminates the need for additional machining, saving both time and cost.

What Industries Use Tube Laser Cutting Machines?

Tube laser cutting machines serve a broad range of industries:

- Automotive: exhaust systems, chassis components, roll cages, and safety parts.

- Aerospace: lightweight tubular structures, engine components, and airframe assemblies.

- Construction & Architecture: structural frameworks, staircases, railings, decorative panels.

- Furniture Manufacturing: chairs, tables, shelving units, and custom designs.

- Agriculture & Heavy Equipment: durable tubular components for tractors, harvesters, and machinery.

- Energy & HVAC: tubing for ducts, piping, and renewable energy structures.

What Are The Advantages Of Tube Laser Cutting Compared To Traditional Methods?

Traditional methods like sawing, drilling, or milling require multiple steps—cutting, deburring, drilling, and finishing. They are slower, less precise, and often waste more material. Tube laser cutting eliminates these inefficiencies by completing all cuts in a single automated process. Key advantages include:

- Speed: Cutting times are up to 3–4x faster than manual methods.

- Precision: Consistent tolerances and clean edges reduce secondary finishing.

- Flexibility: Complex geometries and custom patterns are possible without special tooling.

- Material Efficiency: Optimized nesting reduces scrap and improves yield.

- Automation: Automated loading, rotation, and unloading streamlines production.

How Do Tube Lasers Handle Different Tube Shapes And Sizes?

Tube laser cutting machines are designed with versatile clamping systems and CNC programming to process multiple shapes: round, square, rectangular, oval, and even custom profiles. Automatic rotary chucks securely hold and rotate the tube, while sensors monitor positioning to ensure accuracy during cutting. Quick-change fixtures and software programming allow operators to switch between tube types and diameters quickly, minimizing downtime. This makes them suitable for workshops handling mixed production, as well as large-scale factories requiring consistent throughput across many tube types.

What Is The Maintenance Requirement For Tube Laser Cutting Machines?

Tube lasers are engineered for low maintenance compared to older CO2 laser cutting systems. Key requirements include:

- Regular cleaning of protective lenses, mirrors, and nozzles.

- Checking alignment and calibrating cutting heads.

- Monitoring chiller units and air filtration systems to maintain optimal performance.

- Occasional software updates and mechanical checks of the chuck system.

Are Tube Laser Cutting Machines Cost-Effective?

Yes. While the upfront investment is higher than manual or semi-automatic tools, the long-term benefits are substantial. Fiber lasers use less power, require fewer consumables, and have longer source lifespans than CO2 laser cutting systems. They reduce labor by automating processes, minimize scrap with precise cuts, and eliminate secondary operations like deburring. For businesses cutting tubular components regularly, the ROI (return on investment) is often realized within 1–3 years due to increased productivity, efficiency, and the ability to take on more complex, high-value projects.

Get Laser Cutting Solutions

Unlock the power of precision and efficiency with Maxcool CNC’s laser cutting solutions. Our state-of-the-art machines are engineered to deliver flawless cuts across a wide range of materials, from stainless steels to carbon steels. Whether you’re working on intricate designs, large-scale production, or complex shapes, our advanced laser technology ensures exceptional quality and speed. With customizable options, expert support, and a commitment to innovation, Maxcool CNC is your trusted partner for all your laser cutting needs. Take your manufacturing to the next level—get in touch today and experience cutting-edge solutions designed to elevate your business.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser cutting. Our team will promptly reach out to discuss your unique requirements and guide you through the journey of enhancing your manufacturing capabilities with Maxcool CNC’s laser cutting solutions.