Introduction to Sheet Laser Cutting Machines

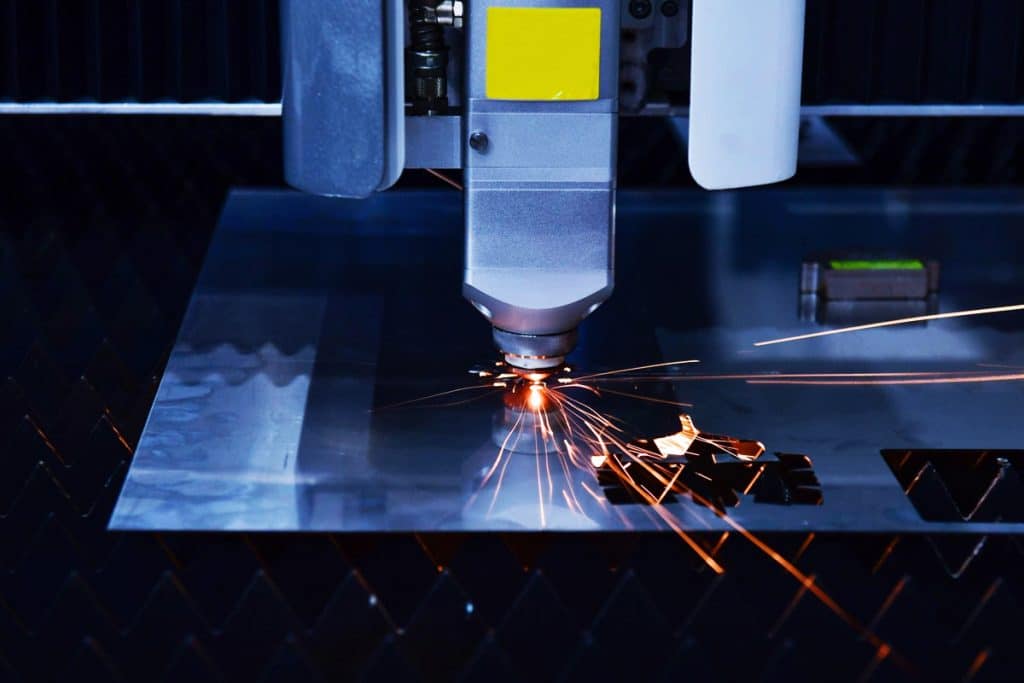

Sheet laser cutting machines are designed specifically for high-precision cutting of flat metal sheets. Powered by advanced fiber laser technology, these machines offer unmatched speed, accuracy, and reliability for a wide range of metals—including stainless steel, carbon steel, aluminum, copper, and brass. Whether you’re producing detailed components or handling high-volume fabrication, sheet laser cutting machines deliver clean, consistent cuts with minimal post-processing. Unlike traditional cutting methods, fiber laser cutting machines use a focused laser beam transmitted through fiber optics to generate intense energy at a fine point. This allows for highly efficient cutting with tight tolerances and reduced material waste. The result is faster production cycles, lower operating costs, and improved overall quality.

Modern sheet laser cutting machines are available in a range of power levels and bed sizes to suit everything from small shops to large-scale manufacturing operations. Many models also include intelligent automation options such as automatic loading and unloading, real-time monitoring, and CNC control systems for streamlined operation. These machines are essential in industries like automotive, aerospace, electronics, furniture, and general metal fabrication. If your operation depends on precision sheet metal work, sheet laser cutting machines are a smart, future-ready investment that boosts productivity and reduces downtime.

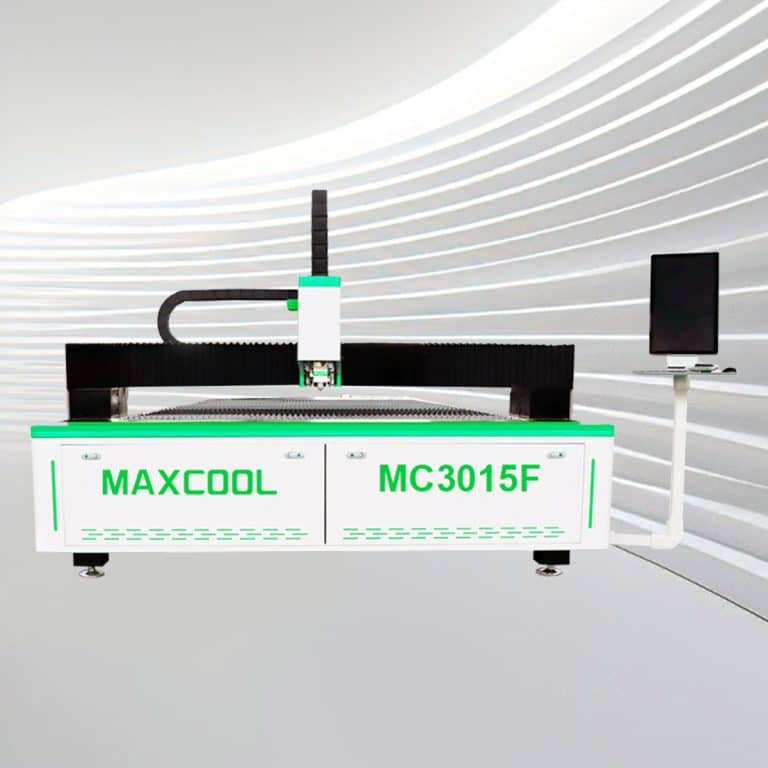

Sheet Laser Cutting Machines

Sheet laser cutting machines are built specifically for processing flat metal sheets with high speed, accuracy, and repeatability. Using advanced fiber laser technology, these machines deliver clean, precise cuts on materials like stainless steel, mild steel, aluminum, brass, and copper. They are ideal for industries that demand tight tolerances and high production efficiency.

Designed for durability and ease of use, sheet laser cutting machines come in a range of power levels and bed sizes to suit different workloads—from job shops handling small batches to large manufacturers running high-volume operations. Their ability to process complex geometries quickly and consistently makes them essential for automotive, aerospace, construction, and general fabrication applications. Equipped with features like CNC control, automated material handling, and nesting software, modern sheet laser cutting machines streamline the cutting process and reduce waste. With minimal maintenance requirements and lower operating costs compared to traditional cutting systems, sheet laser cutting machines offer a long-term advantage.

Applications of Sheet Laser Cutting Machines

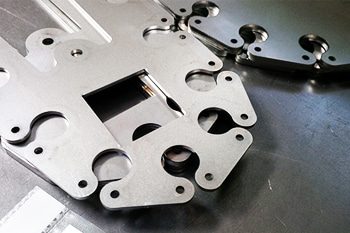

Sheet laser cutting machines are used across a wide range of industries where precision, speed, and clean edge quality are essential. Powered by fiber laser technology, these machines are ideal for cutting flat metal sheets such as stainless steel, carbon steel, aluminum, brass, and copper. In the automotive industry, sheet lasers are used to produce body panels, brackets, and internal structural parts with tight tolerances. In aerospace, they help manufacture lightweight components where accuracy is critical. Fabrication shops rely on these machines to create enclosures, cabinets, signage, and architectural panels with complex geometries.

Electronics manufacturers use sheet lasers to cut intricate parts for housings and control panels. In construction and HVAC, they’re used for cutting ductwork, steel reinforcements, and other sheet-based components. Furniture and appliance makers depend on them for smooth, high-quality cuts in decorative and functional parts. Because they support automated workflows and deliver consistent results, sheet laser cutting machines are also a go-to choice for custom metalwork and high-volume production. Whether you need rapid prototyping or full-scale manufacturing, these machines offer the versatility and efficiency modern operations demand.

Customer Reviews

Our sheet laser cutting machine has dramatically improved both speed and precision in our shop. We’re processing more jobs with fewer reworks, and the software is easy for our team to use. The machine has run reliably since day one, and we’ve already seen a clear return on investment.

RachelOperations Manager

This machine was a game-changer for our small fabrication business. It handles stainless and aluminum sheets with excellent edge quality. We’ve cut production time in half and can now take on more custom work. The learning curve was minimal, and support was responsive whenever we had questions.

CarlosOwner

The sheet laser cutting machine has been one of our most productive investments. We use it daily on 3mm to 12mm steel, and it delivers clean, consistent cuts every time. Automation features have helped reduce labor, and material utilization has improved with the nesting software.

EmilyLead Engineer

Our new sheet laser cutting system gives us the accuracy and repeatability we need. It’s helped us grow into more demanding industries. It also requires far less maintenance than our old plasma system, which has been a huge time-saver.

GregFabrication Supervisor

We run high volumes of sheet metal parts, and this laser has never missed a beat. It’s fast, efficient, and the cuts are consistently clean. The automation and user-friendly controls let our team hit deadlines with ease. Highly recommended for serious production environments.

AnnaProduction Director

Related Resources

Understanding the Operating Costs of Laser Cutting Machines

This article explores the operating cost drivers of laser cutting machines, including electricity, auxiliary gas, consumables, labor, maintenance, downtime, and how to accurately calculate the cost of each part.

What Factors Affect Laser Cutting Speed

This article explores the key factors that influence laser cutting speed, including material properties, laser power, beam parameters, assist gas, and machine setup, providing insights for optimization.

Laser Cutting VS Flame Cutting

This article provides a comprehensive comparison of laser cutting and flame cutting, covering the principles, capabilities, advantages, limitations, and ideal applications of each method.

Frequently Asked Questions

What Are Sheet Laser Cutting Machines?

A sheet laser cutting machine is a specialized CNC-controlled system designed to cut flat metal sheets using a high-powered fiber laser. The laser beam, focused to a fine point, melts or vaporizes the material along a programmed path. These machines deliver exceptional precision, clean edges, and consistent results across complex designs. They’re used in both high-volume manufacturing and small-batch custom fabrication, offering a faster, more accurate alternative to traditional cutting methods like plasma or mechanical shearing.

What Materials Can Sheet Laser Cutting Machines Handle?

Sheet laser cutting machines are optimized for cutting metal sheets. Commonly supported materials include:

- Stainless steel

- Carbon steel / mild steel

- Aluminum (all grades)

- Brass and copper

- Galvanized steel

How Thick Can Sheet Laser Cutting Machines Cut?

Cutting thickness depends on the laser’s power output and the material type. Approximate guidelines:

- 1kW: Up to 5mm stainless steel, 10mm mild steel

- 3kW–6kW: Up to 16mm stainless, 20mm mild steel

- 12kW–20kW+: Up to 30mm or more, depending on gas and cut speed

What Industries Use Sheet Laser Cutting Machines?

Fiber sheet laser cutting machines are used wherever precision metal cutting is required. Common industries include:

- Automotive: Body panels, chassis components, and brackets

- Aerospace: Lightweight precision parts and structural panels

- Construction & HVAC: Ductwork, steel panels, framing parts

- Electronics: Sheet metal enclosures, mounting plates

- Furniture & Appliances: Decorative and functional flat metal parts

- General Fabrication & Job Shops: Custom components, prototypes, and production runs

What Are the Advantages of Fiber Laser Over CO2 for Sheet Cutting?

Fiber lasers offer several key benefits over older CO2 systems:

- Speed: Fiber lasers cut thin to medium metal sheets much faster

- Efficiency: They use significantly less energy

- Maintenance: No mirrors, lenses, or gas-filled tubes to replace

- Reliability: Longer service life, often over 100,000 hours

- Material Range: Easily cuts reflective metals like copper and brass

- Smaller Footprint: Compact design with fewer moving parts

Are Sheet Laser Cutting Machines Easy to Operate?

Yes, especially with modern machines. Most come equipped with intuitive touchscreen interfaces, CNC controllers, and intelligent nesting software that optimizes material usage. Basic tasks like loading materials, selecting cut files, and starting jobs can be learned in just a few training sessions. Advanced users can program custom cutting paths and control machine parameters for more complex work. Built-in diagnostics, remote support, and safety features also make daily operation safer and more efficient.

Can I Automate the Sheet Handling Process?

Yes. Many sheet laser cutting machines can be integrated with automation systems, including:

- Automatic sheet loaders and unloaders

- Pallet changers for continuous operation

- Part sorting and stacking systems

- Smart sensors for material detection and alignment

What Maintenance is Required for Sheet Laser Cutting Machines?

Fiber lasers are known for their low-maintenance operation. However, to keep your system performing at its best, routine checks are essential:

- Lens and Nozzle Cleaning: Prevents debris buildup and ensures clean cuts

- Chiller Maintenance: Keeps the laser source cool

- Air and Gas Lines: Check for leaks and ensure proper flow

- Software/Firmware Updates: Maintain system stability and add new features

- Consumable Parts: Replace nozzles, filters, and lenses as needed

Get Laser Cutting Solutions

Unlock the power of precision and efficiency with Maxcool CNC’s laser cutting solutions. Our state-of-the-art machines are engineered to deliver flawless cuts across a wide range of materials, from stainless steels to carbon steels. Whether you’re working on intricate designs, large-scale production, or complex shapes, our advanced laser technology ensures exceptional quality and speed. With customizable options, expert support, and a commitment to innovation, Maxcool CNC is your trusted partner for all your laser cutting needs. Take your manufacturing to the next level—get in touch today and experience cutting-edge solutions designed to elevate your business.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser cutting. Our team will promptly reach out to discuss your unique requirements and guide you through the journey of enhancing your manufacturing capabilities with Maxcool CNC’s laser cutting solutions.