Introduction to Sheet and Tube Laser Cutting Machines

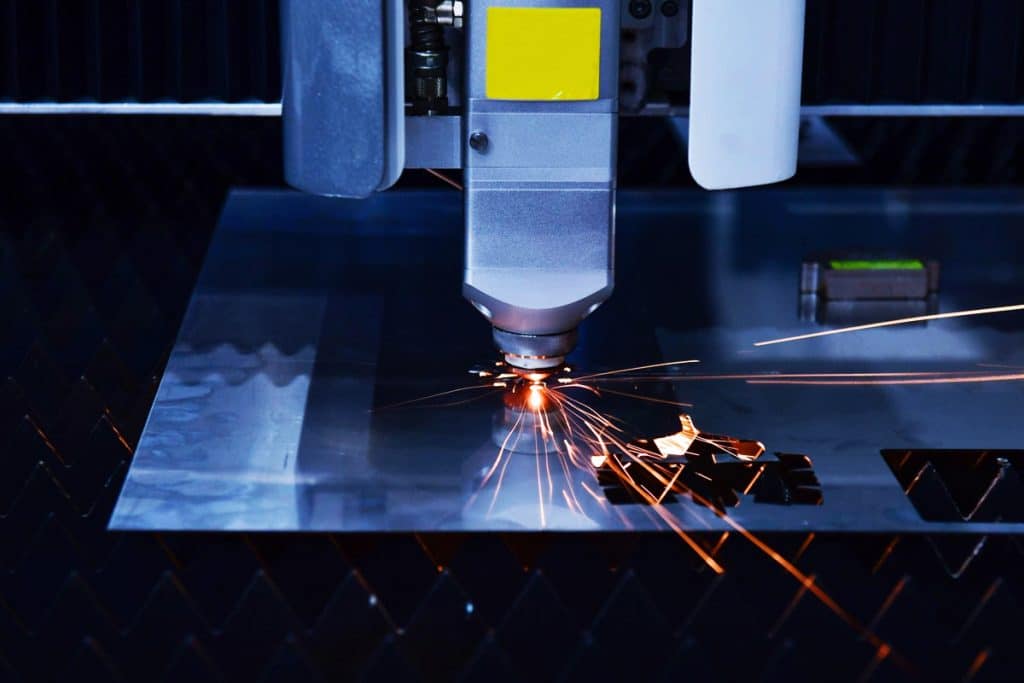

Sheet and tube laser cutting machines are advanced, dual-function systems engineered to cut both flat metal sheets and tubular materials with speed and precision. Powered by laser technology, these machines eliminate the need for separate cutting systems, offering a space-saving and cost-effective solution for businesses that process a variety of metal forms. Equipped with a flatbed for sheet metal and a rotary axis or tube-cutting module for round, square, and rectangular tubing, these machines deliver high cutting accuracy across both platforms. Whether you’re working with stainless steel, carbon steel, aluminum, brass, or copper, sheet and tube laser cutting machines produce clean, consistent edges with minimal post-processing.

Ideal for industries like automotive, aerospace, metal fabrication, and machinery manufacturing, these machines are built to handle complex part geometries, multi-material jobs, and demanding production schedules. Their versatility makes them especially valuable for job shops and manufacturers that require flexibility without sacrificing performance. Modern sheet and tube laser cutting machines come with intelligent CNC controls, automated material handling, and nesting software to streamline workflow and reduce waste. If you’re looking to boost productivity, simplify your setup, and expand your capabilities, sheet and tube fiber laser cutting machines are a powerful investment.

Sheet and Tube Laser Cutting Machines

Sheet and tube laser cutting machines are dual-purpose systems designed to cut both flat metal sheets and tubular materials with high precision and efficiency. Powered by advanced laser technology, these machines deliver clean, accurate cuts on a wide range of materials including stainless steel, carbon steel, aluminum, brass, and copper. What sets these machines apart is their ability to seamlessly switch between sheet and tube cutting within a single platform. The flatbed handles standard sheet metal processing, while the integrated rotary system manages round, square, and rectangular tubes—eliminating the need for separate machines and setups.

Ideal for manufacturers and job shops that need flexibility in their production lines, sheet and tube laser cutting machines save space, reduce labor, and increase output. Most models also include features like CNC control, auto-loading systems, and intelligent software for optimized nesting and workflow. Whether you’re cutting structural tubing or flat components, these machines provide the speed, accuracy, and versatility needed to stay competitive in today’s metal fabrication market.

Applications of Sheet and Tube Laser Cutting Machines

Sheet and tube laser cutting machines are highly versatile tools used across industries that require precision cutting of both flat and tubular metal components. These machines are ideal for operations that handle a wide variety of parts and materials, reducing the need for separate cutting systems and improving production efficiency. In the automotive and transportation industry, they are used to produce chassis components, exhaust systems, brackets, and structural frames—combining both sheet and tube parts in the same workflow. In aerospace, they’re used for cutting lightweight structural tubing and complex sheet profiles with tight tolerances.

Furniture and appliance manufacturers use these machines to create frames, panels, and enclosures from both flat sheet and round or square tubing. In construction, HVAC, and metal fabrication, they are commonly used to cut support structures, ductwork, handrails, and piping systems. Because they handle both material types with high speed and accuracy, sheet and tube laser cutting machines are especially valuable in custom fabrication shops, OEM part production, and industrial contract manufacturing. With automated switching, CNC controls, and high repeatability, these machines help streamline operations, reduce labor, and expand cutting capabilities—all in one system.

Customer Reviews

The sheet and tube laser cutting machine has completely streamlined our workflow. We no longer need separate machines for different materials. It cuts everything cleanly and quickly. The rotary tube system works great, and the overall performance has exceeded expectations.

JasonOperations Manager

This machine has been a huge asset to our team. The ability to cut both flat sheet and tubing in one setup saves us hours each day. Cut quality is excellent, and the software is very intuitive. It’s helped us take on more diverse jobs with confidence.

MariaProduction Supervisor

Investing in a sheet and tube laser cutting system was the best move we made last year. Our production capacity has doubled, and the machine handles complex cuts with ease. The automation features are a big plus, especially for high-volume tube work.

KevinCEO

This dual-function laser cutting machine has made our workflow far more efficient. Switching between sheet and tube cutting is seamless, and the machine handles various materials without issue. Maintenance has been minimal, and support has been excellent.

LisaFabrication Lead

We needed flexibility without sacrificing performance, and this machine delivers both. It easily cuts square and round tubes along with sheet metal, which has simplified our shop layout and saved costs. It's fast, precise, and built for real production demands.

AhmedTechnical Director

Related Resources

Understanding the Operating Costs of Laser Cutting Machines

This article explores the operating cost drivers of laser cutting machines, including electricity, auxiliary gas, consumables, labor, maintenance, downtime, and how to accurately calculate the cost of each part.

What Factors Affect Laser Cutting Speed

This article explores the key factors that influence laser cutting speed, including material properties, laser power, beam parameters, assist gas, and machine setup, providing insights for optimization.

Laser Cutting VS Flame Cutting

This article provides a comprehensive comparison of laser cutting and flame cutting, covering the principles, capabilities, advantages, limitations, and ideal applications of each method.

Frequently Asked Questions

What Are Sheet and Tube Laser Cutting Machines?

A sheet and tube laser cutting machine is a multi-functional CNC system designed to cut both flat metal sheets and tubular materials with one machine. It features a flatbed for sheet metal cutting and an integrated rotary axis or tube chuck for handling round, square, and rectangular tubing. These machines are powered by a fiber laser source, known for its high cutting speed, precision, and energy efficiency. By combining two cutting functions into one unit, this type of machine saves valuable floor space, reduces equipment costs, and increases operational flexibility—especially for manufacturers who work with both material types regularly.

What Materials Can it Cut?

These machines are optimized for cutting a variety of metals, including:

- Stainless steel

- Carbon steel / mild steel

- Aluminum (including reflective alloys)

- Brass and copper

- Galvanized steel

What Tube Shapes and Profiles Can it Process?

Sheet and tube laser cutting machines are capable of cutting:

- Round tubes

- Square and rectangular tubes

- Oval and elliptical tubes

- L- and C-shaped profiles (on select models)

- Custom profiles with the right chunk and software support

What Industries Benefit Most from These Machines?

Any industry working with both flat and tubular metal parts can benefit from a sheet and tube laser cutting machine. Common sectors include:

- Automotive: Chassis components, exhaust parts, structural tubing

- Aerospace: Lightweight structural tubing and brackets

- Construction and HVAC: Ductwork, steel framing, railings, support structures

- Furniture and Appliances: Sheet enclosures, tubular frames

- Agriculture and Machinery: Equipment parts, tube assemblies

- General Fabrication: Mixed material projects and custom work

How Does Switching Between Sheet and Tube Cutting Work?

Modern machines are built for seamless transitions between sheet and tube processing. Typically, the machine bed includes a flat cutting table and an integrated rotary tube cutting module. Switching modes is done through the CNC control interface, where the operator selects the material type and initiates the appropriate setup.

For tube cutting, the rotary chuck engages, aligns the tube, and rotates it precisely as the laser head follows the programmed path. Sheet cutting resumes by disabling the rotary unit and returning to the flatbed operation. Some systems feature automatic height sensing, intelligent calibration, and part detection to minimize setup time and ensure accuracy in both modes.

What Sizes and Lengths of Tubes Can it Handle?

Most standard sheet and tube laser cutters can handle:

- Tube diameters from 20mm to 220mm

- Lengths up to 6 meters (20 feet)

- Advanced models or custom configurations can process:

- Tubes up to 350mm or more in diameter

- Lengths of 8–12 meters, depending on material handling systems

- Wall thicknesses from 1mm to 10mm, based on laser power

Can These Machines be Automated?

Yes, many sheet and tube laser cutting machines support high levels of automation to maximize productivity and reduce labor. Options include:

- Automatic sheet loaders and unloaders for continuous flatbed processing

- Tube auto-feeding systems that load, align, and rotate tubes for cutting

- Pallet changers for rapid job turnaround

- Sorting and stacking systems to organize finished parts

- Integrated nesting software that optimizes material usage

- Smart sensors for material detection, height calibration, and safety interlocks

What Kind of Maintenance is Required?

Sheet and tube laser cutting machines are relatively low-maintenance compared to traditional or CO2 systems. Still, regular care is essential to maintain cutting quality and machine life. Typical maintenance tasks include:

- Daily cleaning of protective lenses, nozzles, and optics to avoid buildup

- Checking and maintaining coolant levels in the chiller system

- Inspecting the fiber optic cable for wear or damage

- Routine lubrication of guide rails, chucks, and mechanical components

- Monitoring air pressure and assist gas systems

- Software updates and performance diagnostics

Get Laser Cutting Solutions

Unlock the power of precision and efficiency with Maxcool CNC’s laser cutting solutions. Our state-of-the-art machines are engineered to deliver flawless cuts across a wide range of materials, from stainless steels to carbon steels. Whether you’re working on intricate designs, large-scale production, or complex shapes, our advanced laser technology ensures exceptional quality and speed. With customizable options, expert support, and a commitment to innovation, Maxcool CNC is your trusted partner for all your laser cutting needs. Take your manufacturing to the next level—get in touch today and experience cutting-edge solutions designed to elevate your business.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser cutting. Our team will promptly reach out to discuss your unique requirements and guide you through the journey of enhancing your manufacturing capabilities with Maxcool CNC’s laser cutting solutions.