Understanding Laser Welding and Its Hazards

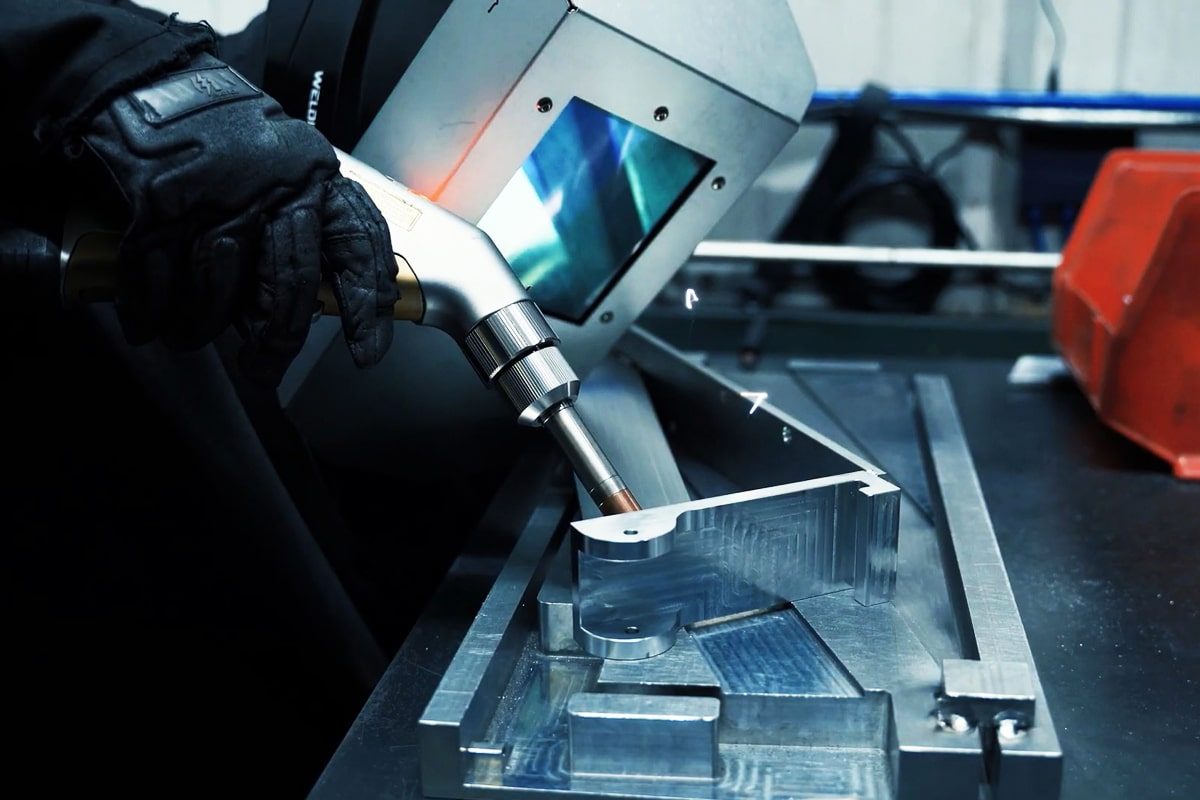

The Laser Welding Process

The beam can be continuous or pulsed, depending on the application:

- Continuous-wave lasers (e.g., fiber or CO2) are used for deep, continuous welds.

- Pulsed lasers (e.g., Nd:YAG) are used for spot or seam welds in delicate components.

Laser Classifications and Risk Implications

Lasers are categorized by their hazard potential:

- Class 1: Completely enclosed; safe under all conditions.

- Class 2: Visible light lasers; safe for momentary exposure.

- Class 3B: Dangerous if viewed directly.

- Class 4: High-power lasers capable of causing burns, blindness, or fires.

Common Hazards in Laser Welding

- Optical Hazard: Invisible infrared radiation (from fiber or CO2 lasers) can cause permanent retinal damage without pain or immediate symptoms.

- Thermal Hazard: The heat from the beam or molten metal can cause severe burns.

- Fire Hazard: Reflected beams or spatter can ignite materials.

- Fume Hazard: Vaporized metals create harmful aerosols containing chromium, nickel, and oxides.

- Electrical Hazard: High-voltage laser power supplies and capacitors can deliver lethal shocks.

- Mechanical Hazard: Automated systems include robotic motion, pinch points, and rotating optics.

- Noise and Radiation Hazard: Pulsed lasers can create acoustic shocks and secondary UV radiation.

Organizational and Administrative Precautions

Establish a Laser Safety Program

Any facility operating Class 4 lasers must have a formal safety management system. The system should include:

- Written safety policies and operating procedures.

- Laser hazard classifications and area designations.

- Defined roles and responsibilities for all personnel.

- Procedures for incident response and medical emergencies.

- Documentation of training, inspections, and maintenance.

The Role of the Laser Safety Officer (LSO)

A Laser Safety Officer is required under international standards. The LSO is responsible for:

- Conducting laser hazard analyses.

- Approving and enforcing safety procedures.

- Authorizing personnel access to laser-controlled areas.

- Ensuring compliance with ANSI Z136 and IEC 60825 standards.

- Maintaining records of training, incidents, and inspections.

Operator Training and Competency

Only trained and certified personnel should operate or maintain laser welding equipment. Training should cover:

- Basic laser physics and system components.

- Potential hazards and protective measures.

- Correct use of personal protective equipment (PPE).

- Emergency procedures for exposure or fire.

- Proper maintenance and troubleshooting practices.

Controlled Access Areas

Laser welding should be performed in a designated, restricted-access area. Key features include:

- Lockable doors or keycard access.

- Illuminated warning signs (“Danger – Class 4 Laser in Use”).

- Door interlocks that disable the laser when opened.

- Curtains or barriers that prevent beam escape.

Personal Protective Equipment (PPE)

Eye and Face Protection

Laser radiation can permanently damage the retina or cornea in a fraction of a second. Therefore:

- Safety eyewear must match the specific wavelength and optical density (OD) of the laser.

- For example, OD 6+ at 1064 nm for Nd:YAG lasers, OD 7+ at 1070 nm for fiber lasers.

- Eye protection must meet ANSI Z136 or EN 207 standards.

- Face shields may be necessary for high-power open-beam operations.

Skin and Body Protection

Laser welding produces infrared radiation and hot spatter. Operators should wear:

- Flame-resistant long-sleeve clothing (cotton, leather, or Nomex).

- Heat-resistant gloves for handling hot components.

- High-top safety boots.

- No reflective or metallic jewelry.

Respiratory Protection

During laser welding, vaporized metals produce toxic fumes and nanoparticles. If local exhaust ventilation is insufficient, respirators must be used:

- For heavy-metal exposure (chromium, nickel, etc.), use a P100 filter.

- For general fume control, use a powered air-purifying respirator (PAPR).

Hearing and Other PPE

Engineering Controls and Equipment Precautions

Beam Enclosures and Guarding

The most effective way to prevent exposure is to fully enclose the beam path. Modern laser welding systems use beam delivery fibers and sealed work cells to prevent accidental reflections. If open-beam configurations are unavoidable, use:

- Laser-safe barriers or curtains rated for the beam wavelength.

- Non-reflective, matte finishes on walls and surfaces.

- Beam traps at the end of the beam path.

Interlocks and Emergency Stops

Access doors, maintenance panels, and enclosures must include interlocks that immediately disable the laser when opened. Emergency stop buttons should be:

- Clearly labeled and illuminated.

- Accessible at multiple locations.

- Connected to both the laser power and motion control systems.

Beam Alignment Safety

Alignment is the most dangerous procedure in laser operation. During alignment:

- Reduce beam power to the minimum possible.

- Wear full PPE, including laser eyewear.

- Use beam blocks and non-reflective targets.

- Remove reflective tools and jewelry.

- Never attempt manual or visual alignment by eye.

Cooling Systems and Electrical Safety

Laser sources and optics generate intense heat. Cooling systems (air or water) must:

- Maintain continuous flow during operation.

- Include sensors for temperature and flow interruption.

- Be checked for leaks, which can cause short circuits or optical damage.

Mechanical and Robotic Systems

Automated laser welding cells often include robotic arms and moving platforms. Safety measures include:

- Installing safety fences and light curtains.

- Programming robot motion limits.

- Conducting dry runs before enabling the laser.

- Using mechanical stops to prevent collisions.

Environmental Precautions

Ventilation and Fume Extraction

Precautions include:

- Installing local exhaust ventilation (LEV) directly at the weld zone.

- Using HEPA filters to capture nanoparticles and activated carbon for gases.

- Ensuring airflow does not disturb shielding gas coverage.

- Conducting air quality tests regularly.

Fire and Explosion Prevention

Laser beams can ignite combustible materials instantly. Fire safety measures include:

- Keeping the area clean and free from flammable materials.

- Storing solvents and chemicals away from the welding zone.

- Keeping Class D extinguishers available for metal fires.

- Using flame-retardant curtains and surfaces.

- Inspecting for and removing accumulated dust (especially aluminum or magnesium).

Environmental Controls for Quality

Temperature and humidity affect optical systems and beam alignment. Excessive vibration or dust can degrade optics and weld quality. Maintain:

- Stable temperature (typically 18–24℃).

- Relative humidity around 40–60%.

- Low-dust, vibration-free floors.

Material Preparation and Process Control Precautions

Cleaning and Surface Preparation

Contaminants such as grease, paint, oxide, and dust interfere with laser absorption and cause porosity. Before welding:

- Clean surfaces with acetone, alcohol, or ultrasonic cleaning.

- Mechanically remove oxides using brushes or mild abrasives.

- Dry parts completely to avoid vapor explosions.

Fixture Design and Clamping

Fixtures must:

- Securely hold components without distortion.

- Be made of non-reflective, heat-resistant materials.

- Minimize vibration and allow consistent beam access.

Shielding Gas and Flow Control

Shielding gas (argon, helium, nitrogen) prevents oxidation and stabilizes the keyhole. However, excessive gas flow can cause turbulence, spatter, and porosity. Precautions:

- Use the correct gas type for the material.

- Verify flow rates and purity.

- Prevent gas accumulation in confined spaces to avoid asphyxiation.

Monitoring and Process Control

Laser welding parameters — power, focus, travel speed, and pulse duration — must be precisely controlled. Automated systems should include:

- Closed-loop power control.

- Back-reflection sensors to detect process instability.

- Data logging for traceability.

Health and Toxicological Precautions

Fume and Gas Exposure

Different metals produce specific hazardous fumes:

- Stainless Steel: Chromium and nickel oxides.

- Aluminum Alloys: Aluminum oxide.

- Galvanized Steel: Zinc oxide.

- Titanium and Magnesium: Flammable metallic vapors.

Ozone and Ultraviolet Radiation

Waste Disposal

Emergency Preparedness

Response to Laser Exposure

If someone is exposed to laser radiation:

- Eye Exposure: Cover the affected eye and seek immediate medical attention from an ophthalmologist.

- Skin Burns: Cool the area with clean water (not ice) and apply a sterile dressing.

- Inhalation Exposure: Move the person to fresh air immediately.

Fire or Electrical Emergencies

In a fire:

- De-energize the laser and disconnect power.

- Use the appropriate extinguisher (Class D for metals).

- Evacuate and alert emergency services if the fire spreads.

For electrical shock:

- Cut power immediately.

- Do not touch the victim until the circuit is isolated.

- Administer CPR if trained.

First Aid and Reporting

Maintenance and Inspection Precautions

Scheduled Maintenance

Regular maintenance ensures both safety and performance:

- Inspect optics for contamination or damage.

- Check cables, cooling lines, and connections.

- Calibrate sensors and focusing mechanisms.

- Clean enclosures and filters.

- Replace worn parts proactively.

Preventive Inspections

The LSO or maintenance engineer should inspect:

- Interlocks and emergency stops are checked monthly.

- Eyewear and PPE weekly.

- Ventilation systems quarterly.

Quality Assurance and Continuous Safety Culture

Process Qualification

Monitoring and Improvement

Implement a continuous improvement cycle:

- Review incidents and near-misses.

- Update procedures and training.

- Conduct safety audits quarterly.

- Reward compliance and awareness.