What Materials Can Be Welded With Fiber Lasers?

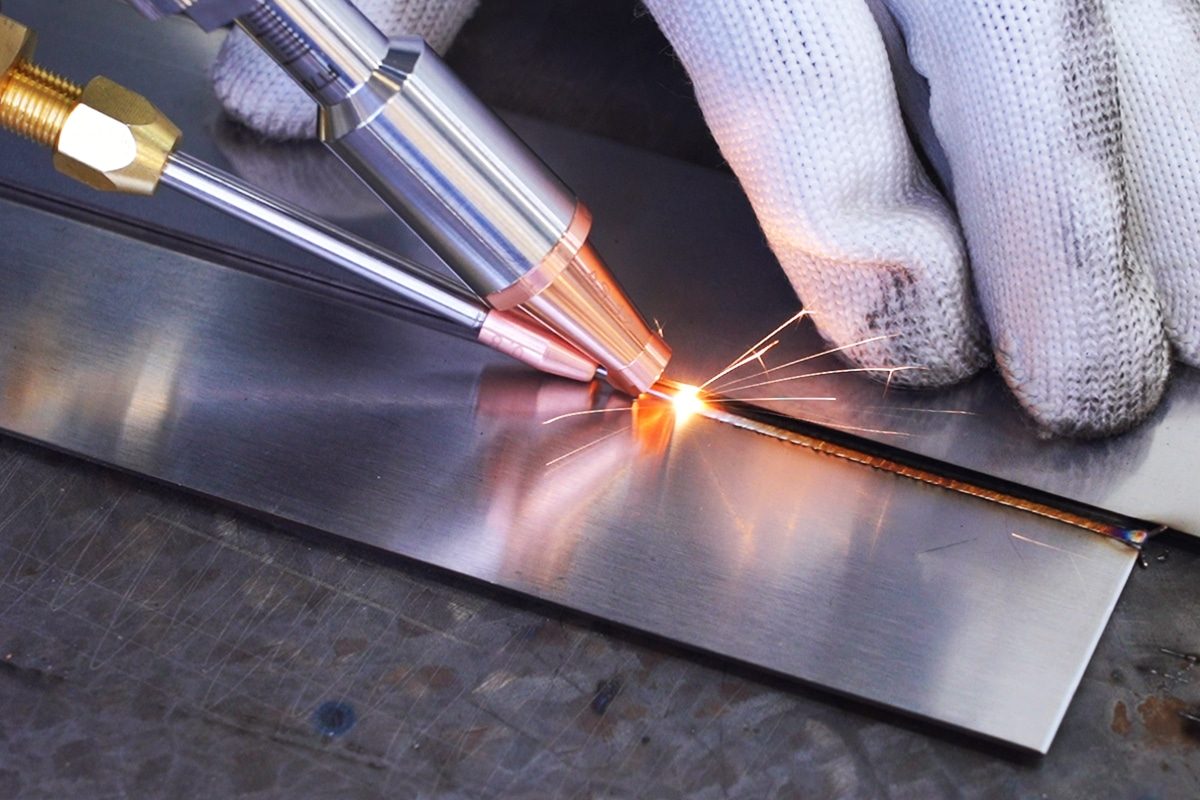

Laser welding has rapidly become one of the most precise and efficient joining technologies available in modern manufacturing. Among the different types of lasers, fiber laser welding stands out for its ability to deliver high power, excellent beam quality, and superior energy efficiency. Unlike traditional welding methods that rely on arcs, filler materials, or physical contact, fiber lasers concentrate light into a tightly focused beam, generating extreme heat in a small area. This allows for deep penetration, minimal heat distortion, and highly accurate weld seams—even on complex or delicate components.

Because of these qualities, fiber laser welding has gained wide adoption across industries such as automotive, aerospace, electronics, and medical device manufacturing. However, not every material responds the same way to this process. Factors like thermal conductivity, reflectivity, and melting point play critical roles in determining whether a material can be successfully welded with a fiber laser. Metals such as stainless steel, aluminum, and titanium are well-known candidates, while others may require specific process adjustments or may not be suitable at all.

This article explores the range of materials that can be effectively welded using fiber lasers, highlighting both their advantages and limitations in real-world applications.

Table of Contents

Fundamentals of Fiber Laser Welding and Material Interaction

Fiber laser welding is fundamentally a process of directing concentrated light energy into a material and using that energy to create a molten pool that fuses components. How well a material responds to this process depends on several intrinsic properties. Understanding these interactions is key to determining weldability and achieving high-quality results.

Wavelength Absorption

Fiber lasers typically operate at a wavelength of around 1.06 µm (near-infrared). Metals absorb light differently at this wavelength. Materials like stainless steel, mild steel, and nickel alloys exhibit strong absorption, which makes them highly suitable for fiber laser welding. On the other hand, aluminum, copper, and gold have high reflectivity at this wavelength, meaning much of the laser energy is reflected rather than absorbed. This can cause process instability or require higher power densities and additional techniques (such as beam oscillation or surface pretreatment) to ensure consistent welding.

Thermal Conductivity

Once absorbed, laser energy must be converted into heat. Materials with high thermal conductivity, such as aluminum and copper, tend to dissipate heat quickly away from the weld zone. This can result in shallow penetration and may require more laser power or optimized welding parameters. Conversely, materials with low thermal conductivity, like stainless steel, retain heat in the weld area, promoting deeper penetration and more stable weld formation.

Melting Point

The melting point of a material directly impacts how much energy is required to create and sustain a molten pool. Metals with lower melting points (such as aluminum alloys) generally require less energy but can also be prone to distortion or excessive evaporation if the heat input is not precisely controlled. High-melting-point materials like tungsten and titanium require more energy to initiate welding, but can produce very strong and stable joints once process parameters are optimized.

Metallurgical Properties

Beyond thermal behavior, the metallurgical characteristics of a material determine how it solidifies after welding. Fiber laser welding produces rapid heating and cooling cycles, which can refine grain structures but may also introduce challenges such as cracking, porosity, or changes in hardness. For example, martensitic steels may experience brittleness due to rapid cooling, while aluminum alloys can suffer from porosity due to trapped hydrogen. Understanding these metallurgical transformations is essential for selecting the right alloys, shielding gases, and post-processing steps.

In essence, the weldability of a material with fiber lasers depends on how effectively it absorbs the laser wavelength, how it manages heat through thermal conductivity, how much energy is required to reach its melting point, and how its microstructure evolves during rapid thermal cycles. Materials with favorable absorption and moderate thermal properties—such as steels, nickel alloys, and titanium—are ideal for fiber laser welding. Others, like aluminum and copper, can still be welded successfully but demand more precise control of parameters and advanced process strategies.

Welding Carbon Steels with Fiber Lasers

Carbon steels are among the most widely used engineering materials, making them a frequent candidate for fiber laser welding. The weldability of carbon steels depends heavily on their composition—particularly the carbon content—and the presence of coatings such as zinc. Fiber lasers, with their high energy density and precision, can successfully weld carbon steels, but different subcategories behave differently under the concentrated heat and rapid cooling conditions.

Mild Steel

Mild steels, also known as low-carbon steels (carbon content typically below 0.25%), are the easiest carbon steels to weld with fiber lasers. Their relatively low carbon content minimizes the risk of cracking and hardness issues. At the fiber laser’s 1.06 µm wavelength, mild steel absorbs energy efficiently, leading to stable weld pools and deep penetration. Additionally, its moderate thermal conductivity and melting point allow for consistent welds without excessive distortion. This makes fiber laser welding highly effective for applications in automotive components, structural parts, and general manufacturing, where mild steel is common.

Medium and High Carbon Steel

Medium carbon steels (0.25–0.6% carbon) and high carbon steels (>0.6% carbon) present greater challenges. The higher carbon content increases the tendency for martensitic transformation during rapid cooling, which can make the weld brittle and susceptible to cracking. Preheating the material, controlling cooling rates, and using post-weld heat treatments are often necessary to reduce internal stresses and prevent cracking. While fiber lasers can produce precise welds in these steels, the process window is narrower, and careful control of parameters such as beam focus, shielding gas, and heat input is essential. These steels are commonly used in applications requiring hardness and wear resistance (e.g., shafts, gears, and high-strength machine components).

Galvanized Steel

Galvanized steel poses unique difficulties due to its zinc coating. Zinc has a low boiling point (907 ℃), much lower than steel’s melting point, and vaporizes quickly when exposed to the concentrated heat of the laser. This vaporization can cause porosity, spatter, and poor weld integrity. Special techniques are often required, such as removing the zinc coating in the weld zone before welding, using optimized joint designs that allow vapor to escape, or applying beam oscillation to stabilize the process. Fiber lasers can weld galvanized steel, but achieving consistent, defect-free joints demands precise preparation and process control.

Fiber laser welding of carbon steels ranges from straightforward to challenging, depending on the steel type. Mild steel welds cleanly and reliably, making it an excellent candidate. Medium and high carbon steels can be welded but require stringent process control to avoid brittleness and cracking. Galvanized steel introduces additional complexity due to zinc vaporization, which must be managed through joint design or pre-treatment. Overall, while fiber lasers can successfully weld all categories of carbon steel, the level of preparation and process adjustment increases with carbon content and coatings.

Welding Stainless Steels with Fiber Lasers

Stainless steels are one of the most common materials processed by fiber laser welding due to their wide use in industries ranging from medical devices and food processing to automotive and aerospace. Their favorable absorption of the fiber laser wavelength (around 1.06 µm) and relatively low thermal conductivity make them highly responsive to precision laser joining. However, the different grades of stainless steel—defined by their microstructure—exhibit distinct behaviors during welding. Understanding these differences is essential for achieving strong, defect-free welds.

Austenitic Stainless Steels

Austenitic stainless steels (such as 304, 316, and 310) are the most widely used and the most weldable with fiber lasers. Their high chromium and nickel content provide excellent corrosion resistance and weldability, while their relatively low thermal conductivity supports deep penetration and stable molten pools. However, challenges can arise from hot cracking due to segregation of impurities (like sulfur or phosphorus) and porosity, especially in grades with higher carbon content. Using high-purity shielding gases (argon or helium), controlling heat input, and optimizing joint design can mitigate these issues. Fiber laser welding of austenitic grades is common in medical instruments, food-processing equipment, and chemical plants.

Ferritic and Martensitic Stainless Steels

Ferritic stainless steels (e.g., 430) contain little or no nickel, making them more affordable but also more prone to grain growth and reduced toughness after welding. Laser welding minimizes heat input and thus reduces grain coarsening, but care is still required to maintain toughness in the heat-affected zone (HAZ).

Martensitic stainless steels (e.g., 410, 420, 440) pose greater challenges. Their higher carbon content means they harden rapidly during cooling, increasing the risk of cracking and brittleness. To weld these steels successfully, preheating and post-weld heat treatment are often necessary to control microstructure and relieve stresses. Fiber lasers can be applied to martensitic grades in high-strength applications (e.g., turbine blades, surgical instruments, and cutlery) where precision and localized heating are advantageous.

Duplex Stainless Steels

Duplex stainless steels (e.g., 2205, 2507) combine austenitic and ferritic microstructures, offering excellent strength and corrosion resistance. However, their two-phase structure makes welding more complex. Maintaining the correct balance between ferrite and austenite is critical, as excessive ferrite can reduce toughness while excessive austenite can compromise corrosion resistance. Fiber lasers, with their high precision and low heat input, can help preserve this balance, but parameter optimization (beam focus, shielding gas selection, and heat input control) is essential. Duplex stainless steels are widely used in oil and gas pipelines, chemical processing equipment, and marine structures, where strength and corrosion resistance are paramount.

Stainless steels are generally well-suited to fiber laser welding, but their weldability varies by type. Austenitic stainless steels are the most straightforward, offering good weld quality with careful control of cracking and porosity. Ferritic and martensitic grades require stricter process management due to grain growth and brittleness risks, with pre- and post-heat treatments often needed. Duplex stainless steels can be welded effectively, but demand precise control to maintain their dual-phase balance. Overall, fiber laser welding provides a versatile and efficient solution for stainless steels, enabling strong, corrosion-resistant joints across a wide range of industrial applications.

Welding Aluminum and Aluminum Alloys with Fiber Lasers

Aluminum and its alloys are widely used in industries such as aerospace, automotive, and electronics due to their high strength-to-weight ratio, corrosion resistance, and formability. However, welding aluminum with fiber lasers presents unique challenges. At the fiber laser wavelength (~1.06 µm), aluminum is highly reflective, meaning much of the laser energy can be reflected rather than absorbed. Additionally, its high thermal conductivity dissipates heat rapidly, often requiring higher power input for stable weld penetration. The presence of an oxide layer (aluminum oxide, Al₂O₃, with a melting point above 2,000 ℃) further complicates the process, as it must be disrupted or melted to form a sound weld. Despite these challenges, fiber lasers can produce high-quality welds in aluminum and its alloys with proper process optimization.

Pure Aluminum

Commercially pure aluminum is among the most challenging to weld with fiber lasers. Its very high reflectivity and thermal conductivity reduce efficiency, often requiring higher laser power and careful focus control. Additionally, pure aluminum is prone to porosity, as hydrogen solubility in liquid aluminum leads to trapped gas during solidification. While welds can be achieved, they typically require tight control of shielding gases (argon or helium) and high laser intensity. Pure aluminum is less common in structural applications but appears in electrical conductors and packaging industries.

Al-Mg Alloys (5xxx Series)

Aluminum-magnesium alloys (e.g., 5052, 5754, 5083) are among the most favorable aluminum alloys for fiber laser welding. The presence of magnesium improves corrosion resistance and weldability compared to other alloy families. However, hydrogen-induced porosity remains a risk, especially in higher-magnesium grades. With optimized shielding and parameter control, fiber lasers can achieve strong, ductile welds with good corrosion resistance, making these alloys suitable for marine applications, automotive body structures, and aerospace panels.

Al-Si Alloys (6xxx Series)

Aluminum-silicon alloys (e.g., 6061, 6082) are more difficult to weld due to their tendency to form hot cracks during solidification. The silicon improves castability but also makes the weld pool brittle if solidification is too rapid. Fiber lasers, with their concentrated heat and fast cooling rates, can exacerbate this cracking tendency. Preheating the material, optimizing filler material (often with higher silicon content), and controlling heat input can mitigate cracking risks. When properly welded, 6xxx alloys are widely used in automotive frames, aerospace components, and transport structures.

Al-Cu Alloys (2xxx Series)

Aluminum-copper alloys (e.g., 2024, 2219) are among the least weldable with fiber lasers. Copper increases strength but severely reduces weldability due to high solidification cracking sensitivity and susceptibility to porosity. The rapid cooling associated with fiber lasers can also produce brittle microstructures. Successful welding often requires filler metals, preheating, and precise parameter optimization—sometimes making alternative joining methods more practical. These alloys are primarily used in aerospace and high-strength structural components, where mechanical properties are critical.

Fiber laser welding of aluminum and its alloys is possible, but varies greatly in difficulty depending on alloy composition. Pure aluminum is difficult due to reflectivity and porosity. Al-Mg alloys (5xxx) are the most favorable, offering strong, corrosion-resistant welds. Al-Si alloys (6xxx) can be welded but require careful control to avoid hot cracking. Al-Cu alloys (2xxx) remain the most problematic, often requiring extensive process modifications. Overall, fiber lasers provide a precise, high-speed welding solution for aluminum, but success depends on understanding each alloy’s unique challenges and tailoring parameters accordingly.

Welding Copper and Copper Alloys with Fiber Lasers

Copper and its alloys are critical in industries such as electrical engineering, plumbing, electronics, and aerospace due to their excellent conductivity, corrosion resistance, and mechanical strength. However, welding these materials with fiber lasers poses significant challenges. At the fiber laser wavelength (~1.06 µm), copper exhibits very high reflectivity, meaning much of the laser energy is initially reflected rather than absorbed. Additionally, copper has exceptionally high thermal conductivity, which rapidly disperses heat away from the weld zone, making it difficult to sustain a molten pool. Despite these challenges, advances in high-power fiber lasers, beam oscillation techniques, and process optimization have made laser welding of copper and its alloys increasingly feasible.

Pure Copper

Pure copper (often used in electrical conductors and heat exchangers) is the most difficult to weld with fiber lasers. Its high reflectivity can damage optical components if not properly controlled, while its high thermal conductivity demands extremely high power densities for deep penetration. Once molten, absorption improves, but weld consistency can still be affected by porosity due to trapped gases. Fiber laser welding of copper typically requires high peak powers, precise focus, and sometimes green or blue laser sources (shorter wavelengths with higher absorption). Successful welds provide excellent electrical conductivity, making them valuable for busbars, battery components, and electronic connectors.

Brass (Copper-Zinc Alloys)

Brass alloys, containing varying amounts of zinc, are also challenging to weld with fiber lasers. The main issue is zinc vaporization: zinc has a low boiling point (~907 ℃), far below copper’s melting point (~1085 ℃). During welding, zinc vaporizes violently, leading to porosity, spatter, and unstable weld pools. This not only compromises weld quality but can also contaminate optics. Techniques to mitigate these problems include preheating, joint designs with venting, beam oscillation, or, in some cases, partially removing zinc coatings before welding. When properly controlled, fiber laser welding of brass can produce joints used in plumbing fittings, decorative components, and electrical hardware.

Bronze (Copper-Tin Alloys)

Bronze, primarily copper-tin alloys (with small amounts of phosphorus, aluminum, or silicon in some cases), is generally more weldable with fiber lasers than pure copper or brass. Tin lowers the thermal conductivity compared to pure copper, improving energy retention in the weld zone. However, bronzes can still suffer from hot cracking and porosity, especially in high-tin alloys. Process optimization—such as carefully controlling heat input and shielding gas composition—is essential for achieving stable welds. Bronze components welded by fiber lasers are used in bearings, bushings, and marine hardware, where corrosion resistance and wear performance are important.

Welding copper and copper alloys with fiber lasers is technically demanding but achievable with the right process strategies. Pure copper is the most difficult due to its reflectivity and thermal conductivity, requiring high power densities and sometimes alternative wavelengths for stable absorption. Brass adds the complication of zinc vaporization, which must be controlled to avoid porosity and spatter. Bronze is comparatively more favorable, with reduced conductivity but still susceptible to cracking and gas entrapment. Overall, fiber laser welding can be successfully applied to copper and its alloys, but achieving high-quality results depends heavily on alloy selection, power density, shielding gas control, and weld design.

Welding Nickel and Nickel Alloys with Fiber Lasers

Nickel and its alloys are widely used in industries such as aerospace, chemical processing, energy, and marine engineering due to their excellent corrosion resistance, high-temperature strength, and oxidation resistance. Fiber laser welding has proven to be an effective method for joining nickel-based materials, thanks to the laser’s ability to deliver highly focused energy with low heat input. Unlike traditional welding processes, fiber lasers minimize distortion, reduce residual stresses, and produce narrow, deep weld seams—advantages particularly important for high-performance nickel components.

Despite their overall weldability, nickel and its alloys present challenges related to cracking, porosity, and microstructural control, especially in alloys designed for extreme environments. Understanding their absorption, thermal behavior, and metallurgical transformations is essential for achieving high-quality welds.

Pure Nickel

Commercially pure nickel (Ni 200/201) welds readily with fiber lasers due to its good absorption at ~1.06 µm and moderate thermal conductivity. It forms stable weld pools with minimal cracking risk and excellent corrosion resistance. The primary concern is porosity, often caused by gas entrapment, which can be mitigated with proper shielding gases (argon or helium) and surface preparation. Pure nickel welds are commonly used in chemical processing, food equipment, and electrical applications.

Nickel Alloys

Nickel alloys are broadly classified based on their alloying elements and service properties. Common families include:

- Nickel-Chromium Alloys (e.g., Inconel, Hastelloy, Monel): These high-performance alloys are used in aerospace engines, gas turbines, and chemical reactors. They weld well with fiber lasers, but rapid solidification can lead to solidification cracking and segregation of alloying elements (such as Nb or Mo). Careful parameter optimization, filler material selection, and controlled heat input are necessary to minimize defects.

- Nickel-Iron Alloys (e.g., Invar, Permalloy): These alloys have controlled thermal expansion properties, making them valuable in electronics, optics, and cryogenic systems. Fiber laser welding works effectively due to its stable absorption, but welds must be carefully controlled to avoid distortion that could compromise dimensional stability.

- Nickel-Copper Alloys (e.g., Monel 400): These alloys offer excellent corrosion resistance in marine and chemical environments. Fiber lasers can produce high-quality welds, though care must be taken to avoid porosity and segregation during solidification.

Metallurgical Considerations

Nickel alloys often contain elements like chromium, molybdenum, or niobium, which enhance strength and corrosion resistance but complicate welding. Fiber laser welding’s narrow heat-affected zone (HAZ) minimizes unwanted grain growth and phase transformations, but hot cracking remains a concern. Preheating, controlled cooling, and post-weld heat treatment may be required for certain alloys to ensure structural integrity.

Nickel and nickel alloys are generally well-suited to fiber laser welding due to their good absorption characteristics and stable weld pool formation. Pure nickel welds cleanly, with porosity as the main concern. Nickel-chromium alloys (e.g., Inconel, Hastelloy) are highly weldable but susceptible to cracking and segregation, requiring precise process control. Nickel-iron and nickel-copper alloys also weld effectively, though dimensional stability and porosity must be managed. Overall, fiber lasers offer a powerful solution for welding nickel-based materials, enabling high-quality, corrosion-resistant, and mechanically robust joints in demanding industries.

Welding Titanium and Titanium Alloys with Fiber Lasers

Titanium and its alloys are highly valued in aerospace, medical, chemical processing, and marine industries due to their exceptional strength-to-weight ratio, biocompatibility, and outstanding corrosion resistance. Fiber laser welding has become one of the preferred methods for joining titanium components because of its ability to deliver deep penetration welds with minimal distortion and extremely narrow heat-affected zones (HAZ). Unlike arc welding, which introduces higher heat input and longer exposure times, fiber lasers reduce the risk of contamination and structural degradation, making them ideal for precision-critical applications.

That said, titanium’s weldability comes with specific challenges. The metal has a strong affinity for oxygen, nitrogen, and hydrogen at elevated temperatures. If the molten or heated material is not perfectly shielded, contamination can lead to embrittlement, porosity, or discoloration. For this reason, fiber laser welding of titanium typically requires high-purity inert gas shielding (argon or helium), extended gas coverage beyond the weld zone, and extremely clean surfaces.

Pure Titanium

Commercially pure titanium (Grades 1–4) welds very effectively with fiber lasers. Its relatively low thermal conductivity compared to aluminum or copper means that laser energy is efficiently retained in the weld zone, leading to stable and deep penetration. The resulting welds generally match or exceed the strength and corrosion resistance of the base metal when proper shielding is applied. However, contamination remains the biggest risk—any exposure to oxygen or nitrogen during welding can make the weld brittle. Pure titanium welds are widely used in chemical equipment, desalination plants, and medical devices where corrosion resistance is paramount.

Ti-6Al-4V Alloy

Ti-6Al-4V (Grade 5) is the most widely used titanium alloy, accounting for more than half of titanium applications. It combines titanium with aluminum and vanadium to deliver excellent strength, fatigue resistance, and corrosion protection. Fiber laser welding of Ti-6Al-4V is feasible and produces narrow, strong welds, but it presents additional metallurgical challenges. Rapid cooling can cause martensitic transformation, leading to increased hardness and potential brittleness in the weld and HAZ. To manage this, controlled heat input, proper joint design, and in some cases post-weld heat treatment (PWHT) are recommended. With optimized parameters, fiber laser welding of Ti-6Al-4V is widely used in aerospace structures, jet engine components, and biomedical implants.

Fiber laser welding is highly effective for titanium and its alloys, but requires strict process control. Pure titanium welds cleanly, delivering strong, corrosion-resistant joints when fully protected from atmospheric contamination. Ti-6Al-4V, while weldable, introduces challenges such as martensitic hardening and embrittlement, which can be mitigated through precise heat management and post-processing. Across both pure titanium and alloys, the key to success lies in exceptional shielding, surface preparation, and parameter optimization. When properly applied, fiber laser welding ensures lightweight, durable, and defect-free titanium joints suitable for the most demanding industries.

Welding Precious Metals with Fiber Lasers

Precious metals such as gold, silver, platinum, and palladium are highly valued for their unique properties, including exceptional corrosion resistance, electrical conductivity, and biocompatibility. They are widely used in industries ranging from jewelry and luxury goods to electronics, medical devices, and aerospace components. Fiber laser welding is particularly attractive for these materials because of its precision, low heat input, and ability to produce fine, defect-free welds without filler materials.

However, precious metals present unique challenges due to their reflectivity, thermal conductivity, and metallurgical characteristics. Each material responds differently to laser energy, and understanding these differences is essential for achieving reliable results.

Gold

Gold is relatively easy to weld with fiber lasers, especially in its pure form. It absorbs the near-infrared laser wavelength reasonably well, and its moderate thermal conductivity helps retain energy in the weld pool. However, gold’s softness and high ductility mean that joint design must be carefully considered to prevent deformation. In alloys (such as white or rose gold), the presence of nickel, copper, or other alloying elements can alter weldability, sometimes leading to porosity or cracking. Fiber laser welding of gold is widely applied in jewelry repair, microelectronics, and dental prosthetics, where precision and aesthetics are critical.

Silver

Silver is the most challenging precious metal to weld with fiber lasers. It has extremely high reflectivity at 1.06 µm and one of the highest thermal conductivities of all metals, which causes most of the laser energy to be reflected or rapidly dissipated. Achieving stable welds requires very high laser power, precise focusing, and sometimes shorter-wavelength laser sources (green or blue lasers) for better absorption. Even with optimized parameters, porosity and incomplete fusion are common risks. Despite the challenges, fiber lasers are used to weld silver in electrical contacts, medical components, and specialized jewelry where no alternative process is viable.

Platinum and Palladium

Platinum and palladium are highly weldable with fiber lasers. Both have good absorption at the fiber laser wavelength and relatively low thermal conductivity compared to gold and silver, making them more responsive to concentrated energy. They also exhibit excellent resistance to contamination during welding, which helps maintain corrosion resistance and mechanical properties in the weld zone. These metals are commonly welded in aerospace sensors, high-temperature equipment, medical implants, and fine jewelry.

Platinum, however, has a high melting point (~1768 ℃), requiring adequate power input, while palladium’s lower melting point makes it slightly easier to weld. Both materials produce stable weld pools and are less prone to cracking or porosity than gold alloys or silver.

Fiber laser welding is a valuable technique for processing precious metals, though each presents unique challenges. Gold welds cleanly, though alloying elements can complicate results. Silver is the most difficult due to its reflectivity and conductivity, often requiring specialized wavelengths or high-power setups. Platinum and palladium offer the best weldability, with stable, high-quality welds achievable under standard fiber laser conditions. Across all precious metals, fiber lasers enable precise, low-distortion welding ideal for applications where material value, aesthetics, and reliability are paramount.

Welding Exotic and Refractory Metals with Fiber Lasers

Exotic and refractory metals such as tungsten, molybdenum, and tantalum are critical in industries that demand exceptional performance in extreme environments. These metals are valued for their very high melting points, corrosion resistance, and strength at elevated temperatures, making them indispensable in aerospace, nuclear energy, electronics, and chemical processing. However, their very properties that make them useful also make them difficult to weld. Traditional arc welding methods struggle with excessive heat input, cracking, and contamination.

Fiber laser welding, with its high energy density, precise control, and minimal heat-affected zones (HAZ), provides a viable pathway to join these challenging materials. The concentrated laser beam allows localized melting, limiting thermal stresses and reducing the risk of large-scale distortion. Still, each of these refractory metals responds differently to laser welding due to differences in melting point, brittleness, and chemical reactivity.

Tungsten

Tungsten has the highest melting point of all metals (~3422 ℃) and exceptional density, making it extremely resistant to heat. However, its weldability is poor due to brittleness and cracking during solidification. Rapid cooling of weld pools often leads to internal stresses and fractures. Fiber lasers can overcome some of these challenges by providing deep, narrow welds with limited heat input, but preheating and controlled cooling are often required. Pure argon or helium shielding is critical to prevent oxidation. Applications include plasma-facing components in fusion reactors, aerospace propulsion systems, and high-temperature furnace hardware.

Molybdenum

Molybdenum (melting point ~2623 ℃) is somewhat more weldable than tungsten but still suffers from grain boundary brittleness and cracking due to its body-centered cubic (BCC) crystal structure. Fiber laser welding reduces overall heat input, limiting grain growth in the HAZ. However, preheating and slow cooling are often necessary to minimize embrittlement. With careful parameter control, molybdenum welds can achieve acceptable ductility and strength, making them suitable for electronic components, aerospace parts, and furnace fixtures.

Tantalum

Tantalum (melting point ~3017 ℃) is the most weldable of these refractory metals. It has excellent ductility and absorbs laser energy more effectively than tungsten or molybdenum, allowing stable weld pools. The main challenge lies in its extreme reactivity with oxygen, nitrogen, and hydrogen at high temperatures. Any contamination leads to embrittlement and weld failure. To ensure quality, tantalum welding requires high-purity argon shielding, extended gas coverage, or vacuum welding environments. When properly welded, tantalum joints maintain outstanding corrosion resistance and biocompatibility, making them valuable in chemical processing equipment, biomedical implants, and high-performance capacitors.

Fiber laser welding opens new possibilities for joining exotic refractory metals that are otherwise very difficult to process. Tungsten is the most challenging due to its extreme melting point and brittleness, often requiring preheating and strict shielding. Molybdenum is more manageable but prone to grain boundary cracking without careful thermal control. Tantalum is the most favorable, producing strong, ductile, and corrosion-resistant welds when contamination is prevented. Overall, while fiber laser welding does not eliminate all challenges, it provides the most effective solution for creating reliable joints in these high-performance metals.

Factors Influencing Weld Quality Across Materials

While material properties such as absorption, conductivity, and melting point largely determine whether a metal is suitable for fiber laser welding, process parameters and external factors are equally critical in achieving high-quality welds. Regardless of whether the material is stainless steel, carbon steel, aluminum, copper, titanium, or refractory alloys, controlling the welding environment and process variables is essential to avoid defects such as porosity, cracking, incomplete fusion, and distortion. The following factors play a decisive role in weld quality across different materials.

Shielding Gas

Shielding gases prevent atmospheric contamination of the molten weld pool and stabilize the laser-material interaction. For most metals, argon is the standard choice due to its inertness and wide availability. Helium is often used for reflective or highly conductive materials like copper and aluminum, as its higher ionization potential improves penetration and reduces porosity. For titanium and tantalum, extended gas shielding or even vacuum welding is necessary to avoid embrittlement from oxygen, nitrogen, or hydrogen absorption. The choice, purity, and flow rate of shielding gas directly impact weld appearance, microstructure, and mechanical performance.

Power Density

Power density (laser power per unit area) governs how much energy is delivered into the material. Too low, and the weld may lack penetration or fusion; too high, and excessive keyhole instability, spatter, or evaporation can occur. Reflective materials (copper, aluminum, silver) require very high power density to initiate and sustain a weld, while steels and nickel alloys typically weld well at moderate levels. Fine-tuning power density ensures deep penetration with minimal defects and distortion.

Joint Design

Joint design must accommodate both the material’s characteristics and the nature of the laser beam. Since fiber lasers produce narrow, focused welds, joints must allow precise access to the laser spot. Butt joints and lap joints are commonly used, though gap control is critical because the narrow beam does not tolerate misalignment. For galvanized or zinc-coated steels, special venting gaps may be designed to let vapor escape and reduce porosity. Good joint design ensures complete fusion, consistent penetration, and reduced defect formation.

Beam Oscillation

Beam oscillation (wobble welding) involves moving the laser beam in controlled circular or elliptical patterns as it travels along the weld path. This technique improves energy distribution, reduces hot cracking, and stabilizes the weld pool in difficult materials such as aluminum alloys, copper, and high-strength steels. It also helps bridge small gaps in joints and minimizes porosity by promoting better gas escape from the molten pool. Beam oscillation is increasingly applied in industrial laser welding to improve process robustness.

Preheating and Post-Weld Treatment

Preheating is often essential for materials with high thermal conductivity (aluminum, copper) or high cracking sensitivity (high-carbon steels, tungsten). By raising the base temperature, preheating reduces thermal gradients, minimizes stresses, and improves weld penetration. Post-weld heat treatments (PWHT) may be required for certain alloys (e.g., martensitic steels, Ti-6Al-4V) to relieve residual stresses, temper brittle phases, or restore ductility. These thermal management strategies ensure weld strength and long-term reliability.

Weld quality in fiber laser welding is not dictated by material properties alone but by the careful control of shielding gas, power density, joint design, beam oscillation, and thermal management. Argon or helium shielding ensures clean welds; optimized power density guarantees proper penetration; thoughtful joint design prevents gaps and porosity; beam oscillation stabilizes difficult weld pools; and preheating or post-weld treatments reduce cracking and brittleness. By balancing these factors with the inherent properties of each material, fiber laser welding can consistently produce defect-free, strong, and reliable joints across a wide range of metals and alloys.

Industrial Applications of Fiber Laser Welding Across Materials

Fiber laser welding is no longer a niche technology—it has become a cornerstone of modern manufacturing thanks to its precision, speed, and ability to join difficult materials with minimal distortion. The flexibility of fiber lasers allows them to weld steels, aluminum, titanium, nickel, copper, and even precious metals, making them invaluable in industries that demand strength, reliability, and efficiency. Below are the major sectors where fiber laser welding has become essential.

Automotive Industry

The automotive sector has been one of the earliest adopters of fiber laser welding. It is used for body-in-white structures, exhaust systems, battery components, and powertrain parts. Mild steel, stainless steel, and aluminum alloys are widely welded for lightweight construction, while copper components in electric vehicle (EV) batteries and motors require precise laser joining to ensure conductivity. Fiber lasers enable high-speed, automated, and repeatable welding, critical for mass production.

Aerospace

In aerospace, weight savings and mechanical integrity are paramount. Fiber lasers are used to weld titanium alloys (e.g., Ti-6Al-4V), nickel-based superalloys (Inconel), and aluminum alloys, producing lightweight, fatigue-resistant structures. Applications include airframes, turbine engine components, and fuel systems. The narrow heat-affected zones provided by fiber lasers reduce distortion in thin-walled aerospace parts, while deep penetration welds ensure strength in load-bearing structures.

Electronics

The electronics industry benefits from fiber lasers’ ability to make microscale welds with minimal heat input. Materials such as copper, nickel, and gold are welded in connectors, sensors, semiconductors, and battery packs. Fiber lasers also support the growing demand for miniaturization, as they can join tiny components without damaging adjacent circuitry. Beam oscillation and pulsed welding techniques further improve weld quality in highly reflective metals like silver and copper.

Medical

Medical applications demand welds that are not only mechanically strong but also biocompatible and free of contamination. Fiber lasers are ideal for welding stainless steel, titanium, and precious metals used in surgical instruments, pacemakers, stents, and implants. The precision of laser welding ensures clean seams with minimal finishing, reducing risks of micro-cracks or contamination that could compromise patient safety. Titanium, in particular, is widely laser-welded for orthopedic and dental implants.

Energy Sector

The energy industry—including nuclear, renewable, and conventional power—relies on materials that can withstand extreme heat, corrosion, and pressure. Fiber lasers are used to weld nickel alloys, stainless steels, and refractory metals in turbine blades, fuel cells, oil and gas components, and heat exchangers. In renewable energy, fiber lasers are crucial for battery welding (lithium-ion cells) and photovoltaic module interconnections, where copper and aluminum must be joined reliably at high volumes.

Jewelry and Luxury Goods

Fiber laser welding also plays a vital role in the jewelry and luxury goods industry, where precision and aesthetics matter as much as strength. Gold, silver, platinum, and palladium are welded to create or repair fine jewelry, watches, and decorative pieces. Fiber lasers produce smooth, nearly invisible seams with minimal heat effects, preserving the appearance and value of high-end products. The same precision extends to luxury electronics and fashion accessories.

Fiber laser welding has become a cross-industry technology, enabling innovation and efficiency in fields ranging from high-volume automotive production to precision-critical aerospace and medical applications. In the automotive industry, it supports lightweighting and EV battery manufacturing. In aerospace, it ensures strength with minimal distortion in titanium and nickel alloys. In electronics, it enables miniaturization and reliable copper/gold connections. In medical manufacturing, it ensures biocompatible, contamination-free welds. In the energy sector, it joins materials for turbines, batteries, and fuel systems under extreme conditions. Finally, in jewelry and luxury goods, it provides flawless, aesthetic welds in precious metals.

Fiber laser welding’s adaptability across diverse materials and industries underscores its role as a critical enabler of modern manufacturing and advanced technologies.

Summary

Fiber laser welding has established itself as one of the most versatile and precise joining technologies in modern manufacturing. Its ability to deliver high power density, deep penetration, narrow weld seams, and minimal distortion makes it suitable for a wide range of metals and alloys. However, the success of the process depends heavily on the material’s properties—absorption at the laser wavelength, thermal conductivity, melting point, and metallurgical behavior—as well as careful control of welding parameters.

Carbon steels and stainless steels remain the most straightforward to weld, with mild steel and austenitic stainless steels showing excellent results. Aluminum and copper alloys, while more challenging due to reflectivity and conductivity, can be welded successfully with high power, beam oscillation, or specialized techniques. Nickel and titanium alloys weld well and are widely used in aerospace, energy, and medical applications, though post-weld treatments may be necessary. Even precious and refractory metals such as gold, platinum, tungsten, and tantalum can be joined under the right conditions.

Across all materials, shielding gases, joint design, power density, and thermal management play a critical role in weld quality. With proper optimization, fiber laser welding delivers strong, precise, and reliable joints that meet the demanding standards of industries from automotive and aerospace to electronics, medical, energy, and luxury goods.

Get Laser Welding Solutions

Selecting the right laser welding solution requires more than just knowing whether a material is weldable—it demands expertise in process optimization, equipment selection, and application-specific requirements. Different metals respond differently to fiber laser welding, and achieving consistent, high-quality results depends on balancing factors such as laser power, shielding gas, joint design, beam delivery, and thermal control. For manufacturers, this often means that off-the-shelf equipment is not enough; what’s needed is a tailored solution that matches material properties with production goals.

At Maxcool CNC, we specialize in providing intelligent laser welding systems designed to handle a wide variety of materials—from carbon and stainless steels to aluminum, copper, titanium, nickel alloys, and even precious or refractory metals. Our machines are built for precision, efficiency, and reliability, making them suitable for industries as diverse as automotive, aerospace, medical devices, electronics, energy, and jewelry. With advanced controls and automation features, our systems ensure deep penetration, minimal distortion, and clean weld seams, even in challenging materials.

Whether you are looking to improve product quality, reduce production costs, or expand into new materials and applications, Maxcool CNC offers the expertise and technology to deliver results. Partner with us to find the laser welding solution that fits your exact needs.