Understanding laser cutting speed is crucial for manufacturers aiming to optimize their production processes. The speed at which laser cutting systems operate influences a range of factors, including throughput, cost efficiency, product quality, and overall process stability. By carefully managing the variables that affect laser cutting speed, manufacturers can achieve a competitive edge by enhancing both operational efficiency and the quality of their products. Below are some key reasons why understanding laser cutting speed is so important.

One of the most significant advantages of optimizing laser cutting speed is the ability to increase throughput. Faster cutting speeds allow manufacturers to complete jobs more quickly, leading to shorter production times. This increased efficiency can be especially valuable in industries where time-sensitive orders are common and production needs to meet tight deadlines. Higher throughput directly translates into the ability to handle more orders, which is a critical factor in increasing overall capacity and meeting customer demands more effectively.

Laser cutting is typically associated with high operational costs due to the expenses related to the equipment, energy, and materials. However, by increasing cutting speed, manufacturers can reduce the cost per part. Faster cutting speeds result in shorter machine run times, which helps minimize energy consumption and wear on components. In addition, faster cutting reduces labor costs associated with machine setup and monitoring, contributing to a more cost-effective operation. Over time, optimizing cutting speed can significantly lower the overall cost of production, particularly in high-volume manufacturing scenarios.

It may seem counterintuitive, but cutting speed also plays a critical role in improving the quality of the final product. When laser cutting speed is carefully balanced with power and focus, it can lead to smoother cuts with fewer imperfections, such as burrs or dross. Optimizing cutting speed helps maintain the integrity of the material by reducing thermal effects that could cause warping or discoloration. With better cut quality, manufacturers can reduce the need for post-processing steps, saving both time and money while ensuring that products meet the desired specifications.

Understanding how to adjust cutting speed in response to various materials and thicknesses grants manufacturers greater flexibility in their operations. Different materials—whether metal, plastic, or composite—require different cutting speeds to achieve optimal results. Moreover, thicker materials may require slower speeds to ensure high-quality cuts, while thinner materials can be processed at higher speeds. By adjusting the speed to match the material and the required cut quality, manufacturers can handle a broader range of materials and applications, increasing their versatility and enabling them to take on a wider variety of projects.

Process stability and repeatability are critical for ensuring consistent results in laser cutting operations. By understanding and optimizing cutting speed, manufacturers can improve these aspects of their process. A consistent cutting speed, paired with other controlled variables like laser power and focus, leads to a more stable cutting process. This reduces the likelihood of defects or variations between cuts, ensuring that the end product is consistent in terms of quality, precision, and appearance. This stability is particularly important in industries where high precision is required, such as aerospace or automotive manufacturing, where even slight variations can result in significant issues.

Understanding laser cutting speed is not just a matter of increasing speed for the sake of productivity; it’s about optimizing the balance between speed, quality, cost, and flexibility. By refining the cutting speed, manufacturers can enjoy higher throughput, reduced operational costs, improved product quality, greater versatility, and more stable, repeatable processes. This comprehensive approach to managing laser cutting speed ultimately helps manufacturers improve their competitive advantage in the marketplace.

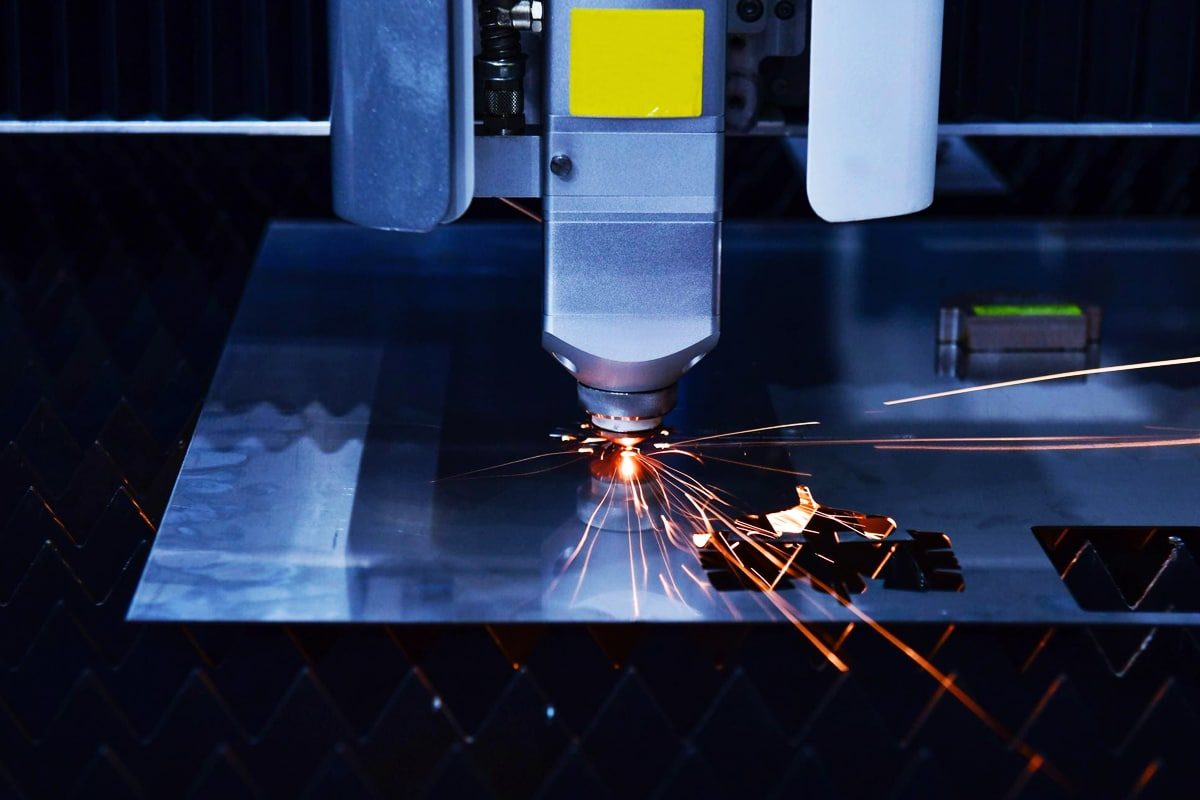

At the heart of laser cutting lies a fundamental physical reality that governs the process: the interaction between energy, material, and heat. This interaction directly influences cutting speed, as well as the quality of the final product. The laser cutting process is based on a focused laser beam that imparts concentrated energy onto a material’s surface. This energy is then absorbed by the material, which results in localized heating, melting, and sometimes vaporization. However, how the material absorbs and responds to the laser’s energy depends on its type and intrinsic properties, making these key factors in determining cutting speed.

Heat management is an essential consideration in laser cutting speed. As the laser heats the material, the temperature increases rapidly, causing the material to melt, burn, or vaporize depending on the material’s composition and the power of the laser. However, the ability of the material to absorb and retain this heat can affect both the cutting speed and quality.

Materials that efficiently absorb heat from the laser will reach their melting or vaporization points more quickly, allowing for faster cutting speeds. Conversely, materials that lose heat quickly (such as those with high thermal conductivity) or are difficult to heat effectively (such as reflective materials) may require slower cutting speeds to ensure the cutting process is effective.

The core physical reality of laser cutting is governed by the intricate relationship between energy, material, and heat. Material type and properties—such as thickness, density, reflectivity, and melting point—play a pivotal role in determining the amount of energy required for cutting, the heat absorption and dissipation, and the speed at which a material can be cut. By understanding these material characteristics and how they interact with the laser, manufacturers can optimize their laser cutting operations for both speed and quality. Efficient energy management ensures that the cutting process is both effective and cost-efficient, making it essential for maximizing productivity and minimizing material waste.

The efficiency and speed of laser cutting are closely tied to the characteristics of the laser itself, particularly its power and beam parameters. The laser’s output power, focus, beam quality, and spot size are fundamental factors that influence how effectively it interacts with the material and how quickly a cut can be made. Optimizing these parameters can lead to better cutting speeds, improved quality, and reduced operational costs. We explore the critical role of laser power and beam parameters in determining cutting performance.

The focus of the laser beam, along with the beam quality and spot size, plays a critical role in both cutting speed and quality. The beam focus refers to how precisely the laser beam is concentrated onto the material’s surface. A well-focused beam ensures that the laser energy is applied in a concentrated spot, increasing the intensity of heat on the material and allowing for a faster cut.

When the laser beam is focused too broadly, it may result in a less efficient use of energy, as the heat is dispersed over a larger area. This results in slower cutting speeds and potentially a lower quality of cut, with rough edges or excess heat-affected zones. On the other hand, a tighter, more focused beam allows for higher energy density at the cutting point, which is critical for making precise cuts at faster speeds.

The beam quality, which refers to the uniformity and coherence of the laser beam, directly impacts its ability to focus effectively. High beam quality results in a smaller and more consistent spot size, which translates into better precision and faster cutting speeds. Low beam quality, on the other hand, can cause fluctuations in the laser intensity, which can result in poor cut quality and slower cutting speeds.

The spot size, which is the diameter of the laser beam’s focal point, also plays a critical role in the cutting process. Smaller spot sizes enable higher precision cuts and better control over the heat input, allowing for faster cutting of thinner materials. A larger spot size can be used for thicker materials, as it distributes the energy over a larger area, but this can also result in slower cuts due to less concentrated heat. The right spot size is essential for balancing cutting speed with the quality of the finished product.

In addition to these parameters, other factors such as the assist gas used (oxygen, nitrogen, etc.), the type of laser (CO2, fiber, or solid-state), and the material properties also come into play. However, understanding the laser’s power and beam parameters is the first step in optimizing cutting speed for any given job.

Laser power and beam parameters—namely, laser output power, focus, beam quality, and spot size—are all essential components in determining laser cutting speed. Higher laser power enables faster cutting, particularly for thicker or denser materials, while a precise focus, high beam quality, and optimal spot size improve energy concentration, leading to faster, more efficient cuts with superior precision. By adjusting these parameters to suit the material type, thickness, and specific cutting requirements, manufacturers can enhance cutting speed while maintaining or even improving the quality of the cut. Optimizing these laser settings helps achieve the most efficient cutting process, reducing operational costs and improving overall productivity in laser cutting operations.

The speed and efficiency of a laser cutting process are not solely determined by the laser’s power and beam characteristics; the process parameters—such as cutting speed, traverse speed, and assist gas type and pressure—play a significant role in optimizing performance. These parameters work in tandem with the laser’s output power to influence cutting speed, quality, and overall process efficiency. Understanding how cutting speed and assist gas interact with laser power is crucial for fine-tuning the cutting process to achieve the desired results.

Cutting speed, or the rate at which the laser moves along the material’s surface, is one of the most direct factors affecting the cutting process. It dictates how quickly the laser can cut through a material and, therefore, influences the throughput of a manufacturing process. The optimal cutting speed is determined by a delicate balance between the material being cut, the laser power, and other process parameters.

If the cutting speed is too high, the laser may not have enough time to effectively heat and melt the material, leading to poor cut quality, such as rough edges, excessive burr formation, or incomplete cuts. On the other hand, if the cutting speed is too low, the material may be subjected to excessive heat, which can cause warping, discoloration, or even a decrease in the material’s structural integrity. Thus, selecting the right cutting speed is essential for ensuring both high productivity and high-quality results.

In addition to cutting speed, traverse speed—the rate at which the cutting head moves when it is not actively cutting—is another important factor. Although traverse speed does not directly affect the cutting action, it impacts overall process time. A higher traverse speed can reduce cycle times, but if not properly synchronized with cutting speed, it can lead to inefficiencies or errors, such as poor alignment or incomplete cuts.

The pressure of the assist gas also plays a vital role in determining cutting speed and quality. Higher gas pressures can help expel molten material more efficiently, reducing the chance of material re-solidifying within the cut and causing blockages. However, if the pressure is too high, it can lead to excessive turbulence and poor cut quality, as it may blow molten material out of the cut zone too aggressively, resulting in rough edges or deformation. Properly regulating the assist gas pressure is critical to achieving the desired cutting speed and quality.

The relationship between cutting speed, assist gas, and laser power is highly interdependent. The laser power must be balanced with both the cutting speed and the assist gas parameters to achieve the optimal cutting conditions. For example, when cutting thicker materials, it may be necessary to reduce the cutting speed to allow sufficient time for the laser to melt the material adequately. In such cases, increasing the laser power or enhancing the assist gas pressure may compensate for the reduced cutting speed.

Similarly, adjusting the assist gas pressure can influence the laser’s effectiveness. For instance, a higher assist gas pressure may improve cutting speed by expelling molten material more quickly and efficiently, reducing the chance of re-solidification. However, the increased energy required to push the molten material out of the cut zone may require corresponding adjustments in the laser power to maintain a clean cut.

In practice, these parameters must be carefully fine-tuned to the specific material being cut and the cutting requirements. By making real-time adjustments to the cutting speed, assist gas type, and laser power, operators can optimize the process for both high speed and excellent cut quality.

Process parameters such as cutting speed, traverse speed, and assist gas type and pressure are critical to achieving the optimal laser cutting speed. The cutting speed directly impacts how quickly a material can be processed, while the assist gas helps remove molten material and maintain a clean cutting environment. The interaction between these factors and the laser’s power must be carefully managed to balance cutting efficiency with material quality. By fine-tuning these parameters, manufacturers can enhance the cutting speed, reduce cycle times, improve the surface finish, and maintain the overall quality of the final product. The right combination of cutting speed, assist gas, and power ultimately leads to a more efficient and cost-effective laser cutting process.

The efficiency and speed of a laser cutting process depend not only on the material being cut, the laser power, and process parameters, but also on the machine, optics, and setup conditions. These factors are integral to ensuring the laser cutting system operates optimally and that the cutting speed is maximized without compromising the quality of the final product. Machine type, laser source, optical components, and the maintenance of these systems play crucial roles in determining how well the system performs over time. We explore the key aspects of laser cutting machines and their components that influence cutting speed.

The choice of laser source directly affects the cutting speed, as each type of laser has different power capacities and beam characteristics. For instance, fiber lasers are known for their high cutting speeds, while CO2 lasers may require slower speeds for optimal results, particularly on thicker materials.

The condition of these optical components directly impacts the efficiency of the laser and, consequently, the cutting speed. Regular inspection and maintenance are necessary to ensure these components function properly.

In laser cutting, achieving the optimal cutting speed is always a balancing act. While higher speeds may increase productivity and throughput, they can also lead to trade-offs in the quality of the cut and material utilization. The delicate balance between speed, cut quality, and material efficiency is at the core of optimizing laser cutting processes. As manufacturers push for faster cutting speeds, it’s important to recognize the potential quality trade-offs that can arise, including issues with kerf width, taper, heat-affected zone (HAZ), and overall surface finish. Additionally, while faster speeds may reduce processing time, they can sometimes result in more waste and lower yield.

The kerf width—the width of the cut made by the laser—can significantly impact the overall quality of the finished part. At higher cutting speeds, the laser spends less time on each point of the material, which can result in a narrower or inconsistent kerf. While this might seem advantageous for increasing cutting speed, it can affect the precision of the cut, leading to parts that are not within the required tolerances.

Taper refers to the angle at which the cut edges are formed, often due to the varying speed of the laser as it cuts through the material. At faster cutting speeds, the laser may have less time to focus and melt the material uniformly, which can result in a more pronounced taper. This taper can affect the alignment and fitting of parts, especially in applications requiring high precision, such as aerospace or automotive components. Slower cutting speeds may reduce taper, allowing for more consistent cuts, but this comes at the cost of longer processing times. Thus, the trade-off is between faster cuts with more taper or slower cuts with better dimensional accuracy.

The speed of laser cutting also affects the quality of the cut edge, surface finish, and the extent of the heat-affected zone (HAZ). The cut edge quality is determined by how smoothly the laser cuts through the material. At higher speeds, the laser may not have enough time to melt and vaporize the material properly, which can lead to rougher edges, dross formation, and incomplete cuts. A high-speed cut can sometimes create more jagged or uneven edges, which might require additional post-processing, such as sanding or grinding, to achieve the desired finish.

The surface finish, or the texture of the material after cutting, is another important consideration. Faster cutting speeds can lead to a less smooth surface, which may be acceptable for some applications but problematic for others that require high-quality finishes. Slower cutting speeds typically allow for a more controlled process, resulting in smoother edges and higher-quality finishes. The trade-off here is clear: faster speeds generally lead to rougher finishes, while slower speeds provide higher quality but at a reduced throughput.

The heat-affected zone (HAZ) is the area around the cut that is affected by the heat generated during the cutting process. At higher cutting speeds, the laser spends less time heating the material, which can reduce the size of the HAZ. While this is advantageous for minimizing thermal distortion and preserving the material’s structural integrity, it can also lead to incomplete cutting or the inability to cut through thicker materials effectively. Conversely, slower cutting speeds allow for more time for the laser to melt and vaporize the material, which can increase the HAZ and cause undesirable effects like warping or discoloration. The challenge is to find the optimal cutting speed that minimizes the HAZ while ensuring a clean and complete cut.

Cutting speed also has a direct impact on the overall efficiency, material yield, and waste produced during the laser cutting process. Faster cutting speeds typically result in shorter cycle times, which increases overall efficiency and throughput. However, this can sometimes come at the cost of precision and quality, leading to increased waste in the form of parts that do not meet specifications. When cut quality suffers, manufacturers may need to discard parts, leading to material waste and lower yield.

Additionally, faster cutting speeds may reduce the time for the laser to interact with the material effectively, potentially leading to uneven cuts, excessive burn marks, or inaccuracies that require rework. Reworking parts or scrapping them altogether contributes to additional costs and material waste. Slower speeds can improve the precision of the cuts and reduce the likelihood of defects, thereby improving the yield and reducing waste. However, this comes at the expense of longer processing times and reduced productivity.

The trade-off between speed and material efficiency is particularly important when dealing with high-cost materials or when cutting thin sheets, where the margin for error is minimal. Faster cutting speeds may waste more material if the cut is not precise enough, whereas slower speeds, though more time-consuming, can help to maximize material utilization.

The trade-offs between cutting speed and process quality are an essential consideration when optimizing laser cutting operations. Faster cutting speeds often lead to increased throughput and efficiency, but they can negatively impact cut quality, such as increased kerf width, taper, and a rougher surface finish. Additionally, faster speeds can affect the heat-affected zone, leading to potential distortion or reduced material integrity. On the other hand, slower speeds may improve cut edge quality, surface finish, and precision but come at the cost of longer cycle times, reduced efficiency, and possibly higher waste. Manufacturers must carefully assess these trade-offs to strike a balance that maximizes productivity while maintaining the required quality standards. By understanding the interactions between speed, cut quality, and material efficiency, manufacturers can optimize their laser cutting processes to meet both production goals and quality requirements.

In laser cutting, achieving optimal performance requires understanding the interplay and trade-offs between various factors that influence cutting speed. The process is governed by multiple variables that are interdependent, and adjustments in one area often have consequences in others. Balancing speed, quality, material usage, and versatility is key to optimizing laser cutting for specific applications. We delve into the complex relationships between key factors, including speed versus quality, power versus material damage, gas efficiency versus cost, focus tightness versus tolerance for variation, and material throughput versus versatility. Recognizing these trade-offs is critical for making informed decisions to improve cutting performance while meeting operational goals.

One of the most significant trade-offs in laser cutting is between cutting speed and cut quality. Increasing the speed of the laser cutting process may seem like an efficient approach to enhancing productivity, but it often comes at the expense of the final cut’s quality. Faster speeds mean that the laser has less time to properly melt, vaporize, or expel material from the cutting zone. As a result, imperfections such as rough edges, burrs, and inconsistencies in the cut can occur. Additionally, cutting speed impacts the precision of the cut, leading to dimensional variations that may not meet required tolerances.

On the other hand, reducing the cutting speed allows the laser to focus more time on each area, resulting in a smoother, cleaner cut with better edge quality and less dross. However, this slower cutting speed reduces throughput and productivity. The key to balancing speed and quality lies in carefully calibrating the laser parameters (such as power, focus, and assist gas) and choosing the appropriate cutting speed for the material thickness and desired quality level. High-quality cuts are important for industries where precision is critical, while faster cutting speeds might be prioritized in applications where productivity is the main goal.

Laser power is another critical factor that impacts cutting speed. Higher power allows for faster cuts, particularly when working with thicker materials. However, higher power levels also result in increased heat input into the material, which can cause thermal distortion, warping, or melting outside the intended cut line. This excess heat can create a larger heat-affected zone (HAZ), which can compromise the integrity of the material, especially for metals sensitive to heat or when fine dimensional accuracy is required.

A large HAZ can also affect the mechanical properties of the material, such as its strength and hardness, which may be undesirable for certain applications. Therefore, while higher power boosts cutting speed, it also increases the risk of material damage. Slower cutting speeds, combined with lower power, help to reduce the size of the HAZ and minimize thermal distortion, but this sacrifices cutting speed and throughput. Balancing power and cutting speed with material considerations is essential to prevent damage and maintain the desired material properties.

The use of assist gases like oxygen, nitrogen, and compressed air is integral to the laser cutting process. These gases not only help to clear molten material from the cutting zone but also play a role in determining cutting speed, quality, and efficiency. Oxygen, for example, increases cutting speed on ferrous materials by promoting an exothermic reaction that assists with the cutting process. Nitrogen, though less reactive, produces cleaner cuts and is used for cutting non-ferrous metals, but tends to result in slower cutting speeds compared to oxygen.

The choice of gas, along with its pressure, directly impacts operational costs. Oxygen tends to be more cost-effective for cutting carbon steel, but it may not provide the same quality when cutting materials like stainless steel, where nitrogen or compressed air is more appropriate. Higher gas pressures can also improve cutting efficiency by enhancing the removal of molten material, but they come with increased operational costs. Manufacturers must weigh the trade-off between achieving faster cuts with higher gas consumption and optimizing gas efficiency to reduce material costs while maintaining high quality.

The focus of the laser beam is critical for determining the precision and quality of the cut. A tightly focused laser produces a small spot size, allowing for higher energy density, more precise cuts, and faster cutting speeds, particularly for thinner materials. However, this tight focus is more sensitive to variations in material thickness and surface conditions. As such, the laser must maintain a consistent focal point, requiring precise setup and calibration. If the focus shifts or is not optimized for the material, it can result in inaccuracies, such as uneven cuts, poor edge quality, or excessive taper.

On the other hand, loosening the focus to increase the tolerance for variation can reduce the need for such fine calibration, but this typically sacrifices precision and increases the likelihood of taper, rough edges, and inconsistent cuts. This trade-off is crucial in applications where high precision is required, such as in the aerospace or electronics industries, where tight tolerances are often demanded. In less stringent applications, manufacturers may tolerate some variation in focus in exchange for the benefits of faster cutting speeds or easier setup.

In laser cutting, material throughput refers to the amount of material processed per unit of time. Faster cutting speeds lead to higher throughput, which is critical in high-volume manufacturing where meeting production quotas is a priority. However, high throughput often limits the range of materials that can be efficiently processed, as the cutting conditions required for different materials (e.g., metals, plastics, composites) vary significantly. The need to adjust parameters like cutting speed, laser power, and assist gas often reduces the overall versatility of the system.

Conversely, more versatile laser cutting systems that can handle a wide variety of materials at varying thicknesses often sacrifice some cutting speed in favor of adaptability. In industries where product variety is essential, maintaining versatility may take precedence, even if it means slightly lower throughput. The trade-off here lies in finding a balance between achieving high throughput in specific applications while maintaining the flexibility to handle a broad range of materials with varying requirements.

The interplay between various factors in laser cutting is complex, with each factor influencing others in ways that must be carefully balanced. Speed and quality are inherently tied, with faster cutting often leading to compromises in precision and surface finish. Power settings, while influencing speed, must be carefully managed to avoid material damage and excessive heat-affected zones. Gas choices and efficiency must be balanced with cost considerations to ensure the process remains both effective and economical. Tight focusing improves precision but increases sensitivity to variations in material, while more flexibility in focus can reduce speed and quality. Finally, while high throughput is essential for efficiency, it can limit the versatility of the laser cutting system. Manufacturers must consider all these interdependent factors and make trade-offs based on their specific production needs and material requirements. Understanding these dynamics is crucial for optimizing laser cutting performance and achieving the best possible results in terms of both speed and quality.

Optimizing laser cutting speed is a crucial factor in achieving both high productivity and quality in manufacturing. Laser cutting offers tremendous flexibility and precision, but the interplay of multiple variables requires careful management to ensure that the process is as efficient as possible. By considering factors such as laser power, beam parameters, assist gas, machine maintenance, and the balance between speed and quality, manufacturers can significantly improve cutting performance. We will explore practical guidelines and strategies that can help optimize laser cutting speed while maintaining high-quality results.

One of the fundamental strategies for optimizing laser cutting speed is selecting the appropriate laser power for the material and thickness being processed. Laser power directly affects the cutting speed, with higher wattage allowing for faster cutting of thicker materials. For thin materials, using high power may lead to excessive heat, which can affect cut quality. For instance, cutting thin metals or plastics with too much power could result in unwanted material warping or edge roughness. Conversely, thicker materials require more power to ensure the laser can penetrate and melt or vaporize the material effectively.

To optimize cutting speed, it is essential to match the laser’s wattage to the material’s properties and thickness. In industrial settings, knowing the recommended power settings for various materials and thicknesses helps in avoiding unnecessary adjustments and ensures optimal processing times.

Beam parameters, including focus, lens, spot size, and beam quality, have a direct impact on laser cutting speed. A well-focused laser beam ensures high energy density at the cutting point, which can significantly increase cutting speeds. If the beam is too wide or unfocused, energy is dispersed, leading to inefficient cuts and slower speeds.

The lens plays a vital role in ensuring the beam remains focused properly. Lenses should be kept clean and free from damage to maintain their ability to focus the laser effectively. Over time, lenses may degrade or get dirty, resulting in reduced beam quality, which can lead to slower cutting speeds and poor cut quality.

Spot size, or the diameter of the laser beam, is another critical factor. Smaller spot sizes allow for higher precision, which can be useful for fine cuts but may reduce cutting speed for thicker materials. Larger spot sizes are better suited for cutting thicker materials at faster speeds, as they deliver more energy to the material at once. However, larger spots may compromise cut precision, especially on thinner materials.

Finally, beam quality, or the coherence and uniformity of the laser beam, influences how effectively the laser can focus and cut. A high-quality beam leads to a more consistent and controlled cutting process, enhancing both speed and quality. Regular calibration of the laser cutting system ensures that beam quality is maintained at optimal levels.

The choice of assist gas and its pressure can have a significant impact on cutting speed, quality, and efficiency. The correct gas type must be chosen based on the material being cut. For instance, oxygen is ideal for cutting ferrous metals like carbon steel, as it accelerates the cutting process by contributing to the exothermic reaction that helps melt the material. However, using oxygen on non-ferrous materials, such as stainless steel or aluminum, can lead to oxidation and rough cut edges. In these cases, nitrogen is often preferred, as it produces cleaner cuts but generally results in slower cutting speeds compared to oxygen.

The pressure of the assist gas is equally important. Higher gas pressures can help expel molten material more efficiently from the cut zone, maintaining a clean cut and improving cutting speed. However, excessive gas pressure can lead to turbulence, which may negatively impact cut quality, causing issues like dross formation or poor edge finishes. The optimal gas pressure balances cutting speed with high-quality cuts and is typically dependent on the material type and thickness.

One of the most effective strategies for optimizing laser cutting speed is conducting iterative testing and parameter tuning. While manufacturers can start with recommended settings for material types and thicknesses, these values often serve as starting points. Fine-tuning parameters like laser power, cutting speed, assist gas type and pressure, and beam focus is essential to achieve optimal cutting performance for each specific application.

By conducting a series of tests under different conditions, manufacturers can identify the most efficient combination of settings that result in the fastest cutting speeds with acceptable quality. Parameter tuning should be performed regularly, as changes in material properties, laser performance, or environmental conditions can all affect cutting speed. In some cases, even small adjustments to parameters like cutting speed or laser power can make a significant difference in efficiency and quality.

The maintenance of the laser cutting machine and its optical components is crucial for sustaining optimal cutting speed over time. Regular maintenance ensures that the laser cutting system continues to perform at its best, minimizing the risk of slowdowns or quality issues caused by machine wear.

Optical components like lenses, mirrors, and nozzles should be regularly cleaned and inspected for wear or damage. Dirty or damaged optics can cause beam distortion, resulting in inefficient cuts and slower speeds. Nozzles must be carefully maintained to ensure proper gas flow, as even slight blockages or wear can disrupt the cutting process.

In addition to optics, the laser’s mechanical systems, such as the cutting head, motors, and drives, must be kept in top condition to ensure smooth movement and accurate cutting. Any misalignment or mechanical malfunction can cause slowdowns, inaccurate cuts, or inconsistent speed. Ensuring a stable setup, with accurate calibration and alignment, is key to maintaining consistent cutting speed and high-quality output.

Finally, it’s important to recognize that optimizing laser cutting speed involves balancing speed with quality. While faster cutting speeds generally improve throughput, they may compromise the quality of the cut, including factors like kerf width, edge smoothness, and the heat-affected zone (HAZ). In many applications, some level of quality trade-off is acceptable, but manufacturers should define the acceptable boundaries of these trade-offs based on their specific needs.

For example, in high-volume production, speed might take precedence over precision, and manufacturers may tolerate slightly rougher edges to meet production targets. In contrast, industries such as aerospace or electronics, where precision and surface finish are critical, may require slower cutting speeds but higher-quality results. It’s essential to define these acceptable trade-offs ahead of time to ensure the cutting process is optimized for both performance and the specific quality standards of the application.

Optimizing laser cutting speed requires a holistic approach that takes into account laser power, beam parameters, assist gas settings, machine maintenance, and the balance between speed and quality. By matching laser power to the material and thickness, optimizing beam parameters, tuning assist gas type and pressure, and conducting regular testing and parameter tuning, manufacturers can maximize cutting speed without sacrificing quality. Additionally, maintaining the machine and optics in peak condition and understanding the trade-offs between speed and quality are crucial strategies for ensuring long-term cutting efficiency. By applying these practical guidelines, manufacturers can achieve faster, more efficient laser cutting processes while maintaining the desired level of product quality.

While laser cutting is an efficient and highly versatile technology, it is not without its challenges and limitations. The pursuit of faster cutting speeds comes with several trade-offs that must be carefully managed to ensure optimal results. Manufacturers need to understand how various factors—ranging from material limitations to machine wear—can impact both the speed and quality of the cutting process. We explore the challenges that arise in laser cutting, including material limitations, heat-related distortions, gas consumption, quality degradation, and the complexity of optimization. Additionally, we will examine how machine maintenance, environmental concerns, and operational constraints play a role in the overall process.

Material properties are one of the most significant factors limiting laser cutting speed. Different materials—whether metals, plastics, or composites—have varying responses to laser energy, which directly affects cutting speed. For example, metals with high reflectivity, such as copper and brass, tend to reflect a large portion of the laser energy, requiring more power or slower cutting speeds to achieve clean cuts. On the other hand, materials with low thermal conductivity, such as certain plastics or ceramics, may absorb laser energy more efficiently, allowing for faster cutting speeds.

Additionally, as material thickness increases, cutting speed tends to decrease. Thick materials require more laser power and slower speeds to achieve a clean, complete cut. In contrast, thinner materials can be processed faster but may require more precise control to avoid issues like warping or surface roughness. These material limitations make it essential for manufacturers to understand the specific characteristics of the material being cut to ensure that cutting speeds are appropriately adjusted.

Laser cutting involves intense localized heating, which can lead to various heat-related distortions or damage, particularly at higher speeds or with higher power settings. The heat-affected zone (HAZ), which is the area surrounding the cut, can experience changes in material properties due to excessive heat, such as warping, discoloration, or altered mechanical properties. These distortions are particularly problematic in materials that are sensitive to heat, such as aluminum, titanium, or certain plastics.

Faster cutting speeds can reduce the time the material is exposed to the laser, thus minimizing the size of the HAZ. However, if the speed is too high, it may not provide sufficient heat to cut through thicker materials, potentially resulting in incomplete cuts or rough edges. Balancing speed with heat input is a constant challenge to ensure that the material remains intact and the final cut meets the desired quality standards.

The use of assist gases such as oxygen, nitrogen, and compressed air is vital to the laser cutting process, as these gases help expel molten material and maintain an optimal cutting environment. However, higher assist gas pressures and the use of more reactive gases like oxygen can increase gas consumption, raising operational costs. In industries where gas efficiency is critical, excessive consumption can become a significant cost burden.

Moreover, there are environmental and safety considerations associated with gas use. Certain gases, particularly oxygen, can pose safety risks if not properly handled, as they can promote combustion or contribute to harmful reactions when interacting with some materials. Additionally, the disposal of gases and other by-products, including fumes and dust generated during cutting, must be managed in accordance with environmental regulations to reduce harmful emissions. In environments with strict safety and environmental standards, controlling gas use becomes a key challenge in optimizing laser cutting speed.

A major challenge in optimizing laser cutting speed is the potential degradation of quality and consistency. While higher speeds can improve throughput, they often result in lower-quality cuts. Speeding up the process reduces the time the laser has to focus on the material, which can lead to rough edges, poor surface finish, and increased kerf width. These quality issues are particularly problematic in applications where precision and fine finishes are crucial, such as in the aerospace, automotive, or electronics industries.

Defects like excessive taper, heat-affected zones, and dross formation become more prominent as cutting speed increases. Additionally, there is often variability in the results when operating at high speeds. Inconsistent cuts or imperfect edges can lead to the need for rework or rejection of parts, increasing production costs and reducing overall efficiency. Manufacturers must find a balance between cutting speed and acceptable quality standards to ensure that speed does not compromise the final product.

Optimizing laser cutting speed is a complex and dynamic process that requires constant adjustments to multiple parameters, including laser power, cutting speed, assist gas type, and focus. Finding the optimal settings for different materials, thicknesses, and cutting requirements is not a straightforward task. As material properties and environmental conditions change, the ideal combination of settings will vary, requiring ongoing testing and fine-tuning.

Furthermore, optimizing speed while maintaining quality requires balancing multiple trade-offs, such as the relationship between cutting speed and kerf width, or the impact of assist gas pressure on speed versus surface finish. This complexity is compounded by the need to continuously monitor and adjust machine parameters, making it a resource-intensive process. Manufacturers need to invest in expertise and tools to continuously optimize laser cutting parameters and achieve the best possible results.

The performance of laser cutting machines declines over time due to wear and tear. Components like laser tubes, optics, mirrors, and mechanical parts (such as motors and drives) degrade with use, which can reduce cutting speed and overall efficiency. Worn-out parts can result in misalignment, beam distortion, and decreased laser power, all of which contribute to slower cutting speeds and lower-quality cuts.

To maintain consistent performance and cutting speed, regular maintenance is required, including cleaning lenses, calibrating the machine, and replacing worn parts. Failure to perform routine maintenance can lead to increased downtime, inconsistent performance, and higher operating costs. Preventive maintenance schedules and timely replacement of components are essential to avoid significant production disruptions and ensure the machine operates at optimal speed and precision.

Environmental factors, such as temperature, humidity, and air quality, can also affect the performance of laser cutting systems. For example, excessive moisture or dust in the air can impair the performance of the laser, affecting both speed and cut quality. Similarly, high or low temperatures can impact material properties and alter how the laser interacts with the material, necessitating adjustments to the laser power or cutting speed.

Operational constraints, including limited space, energy supply, and workforce expertise, can also limit the ability to achieve optimal laser cutting speeds. In smaller workshops or facilities with limited power capacity, achieving high cutting speeds may be difficult due to energy constraints. Similarly, inexperienced operators or a lack of training can result in inefficient machine use, leading to slower speeds and increased errors.

While laser cutting offers remarkable speed and precision, there are numerous challenges, limitations, and trade-offs that manufacturers must consider. Material limitations, heat-related distortions, and gas consumption are just a few of the obstacles that can impact cutting speed. Quality degradation and defects become more pronounced as cutting speeds increase, requiring careful management to ensure the desired result. Optimization of cutting parameters is complex, often requiring ongoing testing and adjustments, and machine wear and environmental factors can further complicate the process. Balancing these factors and making informed decisions about cutting speed, quality, and efficiency is essential for achieving optimal results in laser cutting applications. By understanding and addressing these challenges, manufacturers can maximize their cutting speed while maintaining the high standards of quality and performance required for success in competitive industries.

Laser cutting is a highly efficient and versatile manufacturing process, but the speed at which it operates is influenced by a variety of factors that must be carefully managed to achieve optimal results. Throughout this article, we have explored the key factors that affect laser cutting speed, including material properties, laser power, beam parameters, assist gas settings, machine conditions, and the balance between speed and quality.

Material properties, such as thickness, reflectivity, thermal conductivity, and density, play a significant role in determining the appropriate cutting speed. Thicker, denser, or more reflective materials generally require more laser power and slower cutting speeds to achieve clean, precise cuts. Understanding the specific characteristics of each material is essential for adjusting the laser parameters to maintain efficiency and quality.

Laser power is another critical factor; higher wattage enables faster cutting, particularly for thicker materials, but can also lead to heat-related issues, such as warping or a larger heat-affected zone. Beam parameters, including focus, spot size, and beam quality, also directly influence cutting speed by affecting the energy density at the material surface. Optimizing these parameters ensures that the laser beam remains efficient and precise.

Assist gases, such as oxygen or nitrogen, are used to remove molten material and maintain a clean cutting environment. The choice of gas and its pressure can significantly impact cutting speed, with oxygen typically enabling faster cuts, while nitrogen offers cleaner results but at slower speeds.

In addition to these factors, maintaining the machine, optics, and setup conditions is essential for ensuring consistent performance. Regular testing and parameter tuning help optimize cutting speed, while machine wear and environmental conditions can affect the system’s efficiency over time. Finally, understanding the trade-offs between cutting speed and quality is key to balancing productivity with the required cut precision.

By carefully considering and optimizing these variables, manufacturers can enhance both the speed and quality of their laser cutting processes, leading to improved productivity, reduced costs, and higher-quality products.