What Are the Hazards of Laser Cutting Machines?

Laser cutting machines concentrate a lot of power in a small space: a high-energy light source, precision optics and motion, high-pressure gases, extraction fans, and control electronics. That same concentration makes them incredibly useful—and risky when controls slip. This guide goes deep. It explains how laser cutting machines work, details every major hazard with Possible Problems → Causes → Control Measures, flags materials that deserve extra caution, and shows how to build a safety program that actually works on the floor.

The goal is practical mastery. Use this as a blueprint for training, SOPs, audits, and day-to-day decisions at the machine.

Table of Contents

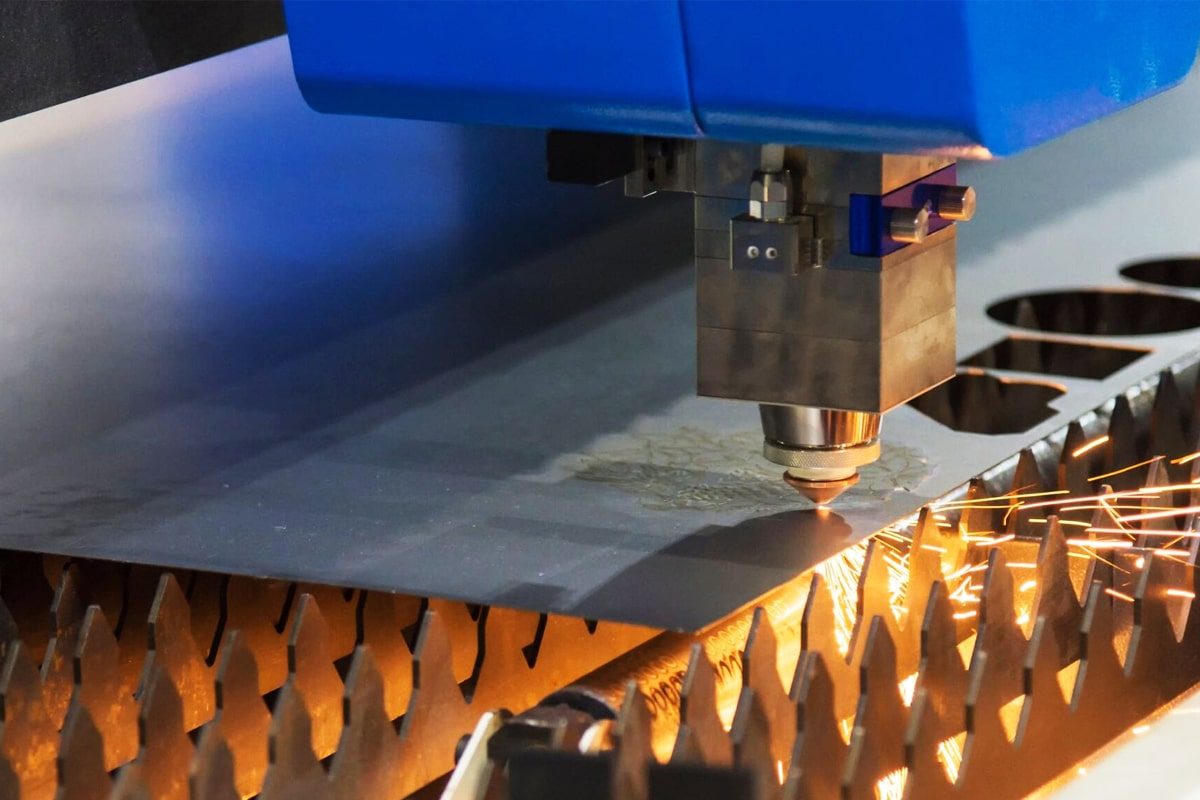

How Laser Cutting Machines Work

Laser cutting is heat and momentum applied with surgical precision. Understanding the subsystems helps you predict where hazards emerge.

The Laser Source and Wavelength

Most cutting systems use one of two families:

- CO2 lasers (10.6 μm, far-infrared): Excellent for nonmetals—wood, paper, leather, rubber, acrylics, many plastics. The beam is invisible. The main eye risk is to the cornea and lens; skin absorbs strongly.

- Fiber/solid-state lasers (~1.0–1.1 μm, near-infrared): Optimized for metals—carbon steel, stainless, aluminum, copper, brass—and high-speed marking. Invisible beam; the primary eye risk is retinal because near-IR penetrates deeper. High brightness increases the danger of specular reflections.

Externally, many shop machines are Class 1 (safe for casual exposure when closed), but they house an embedded Class 4 source. Any open-frame system—or any time you open an interlocked door while the beam could emit—creates Class 4 exposure conditions.

Optics and Beam Delivery

Mirrors guide the beam; lenses focus it; a protective window shields optics from spatter and resin. A contaminated optic absorbs heat, distorts the beam, scorches material, and can suddenly crack. The nozzle standoff controls gas dynamics and clearance.

Motion Platform

A gantry moves the head in X–Y. Some systems control Z (table/auto-focus). Rotary attachments turn the work for tubes and cylinders. Motion introduces pinch points, entanglement hazards, and the potential for ejected parts if small slugs tip into the kerf.

Assist Gas

Gas clears the molten material and shapes the cut chemistry:

- Air: General purpose; inexpensive; can leave some oxidation.

- Nitrogen: Inert; produces a bright, oxide-free edge on stainless and aluminum.

- Oxygen: Accelerates exothermic reactions for faster steel cutting but adds fire risk.

Gases arrive through regulators, hoses, and solenoids—this is a compressed-gas system with all the usual risks.

Ventilation and Filtration

Cuts produce fumes, vapors, and ultrafine particulates. Capture begins at the enclosure or hood, then runs through a filtration train—typically prefilter → HEPA for particulates → activated carbon for VOCs—before discharge or safe recirculation. Airflow must be adequate and monitored.

Controls and Parameters

Quality and safety hinge on speed, power, pulse frequency, duty cycle, focus height, nozzle size, standoff, gas type, and pressure. Wrong parameters are a leading cause of fires, fumes, poor edges, and crashes.

Hazard Categories

Each section lists Possible Problems, Causes, and Control Measures you can drop straight into SOPs, checklists, and training.

Optical (Laser Radiation) Hazards

Possible Problems

- Permanent eye injury from direct or specularly reflected beams.

- Retinal burns (fiber/near-IR) or corneal injury (CO2/far-IR).

- Skin burns with open-beam service.

- The viewing window transmits hazardous light due to the wrong material or damage.

Causes

- Interlocks bypassed or failed; doors open during emission.

- Mirror-like reflections from polished metals, glossy coatings, wet/oily surfaces.

- Wrong eyewear (incorrect wavelength/optical density), scratched/delaminated filters, counterfeit glasses.

- DIY or non-rated replacements for viewing windows.

- Open-frame machines without a controlled area or barriers.

Control Measures

- Engineering: Keep the system fully enclosed and interlocked for normal operation. Install certified viewing windows matched to the wavelength and internal power; guard against substitution. On fiber systems cutting reflective metals, use back-reflection protection (isolators/sensors) to protect the source.

- Administrative: Define a laser-controlled area for any open-beam work. Post laser class and wavelength, restrict access, and use temporary barriers and beam stops for alignment. Use low-power pilot beams for checks. Maintain a register of approved eyewear by wavelength with inspection intervals.

- PPE: For open-beam tasks or open-frame systems, wear laser protective eyewear with the correct optical density and wavelength range; verify markings before use. Add face shields and skin coverage for high-power or alignment tasks.

Fire and Explosion Hazards

Possible Problems

- Workpiece ignition (paper, wood, cardboard, leather, foams, fabrics, many plastics).

- Honeycomb/slat bed fires that spread beneath the work.

- Smoldering embers carry into filters/ducts, causing delayed fires.

- Oxygen-assisted cuts turn small flames into sustained fires.

- Dust deflagration in collectors occurs when fine combustibles become suspended and ignited.

Causes

- Excess power, too-slow speed, wrong focus height, and poor nozzle standoff.

- Debris/resin buildup in bed and plenum; accumulated fines act as fuel.

- Weak or failed exhaust; clogged filters; blocked plenum; ignored alarms.

- Oxygen leaks or mis-set pressures elevate oxygen concentration in the cabinet.

- No spark arrestor; no post-purge; embers remain hot after shutdown.

Control Measures

- Engineering: Size local exhaust ventilation for worst-case jobs; include spark arrestors, pre-filters, HEPA, and activated carbon as materials require. Prefer steel slats or flame-retardant beds. Install thermal/optical fire detection and, where justified, automatic suppression in the cabinet or collector. Interlock assist-gas flow; add pressure/flow monitoring. Program post-purge airflow after cuts to clear heat and embers.

- Administrative: No unattended cutting of flammables (foams, fabrics, paper, thin woods, many plastics). Use a pre-use checklist: clean bed and crumb trays, verify exhaust/alarms, confirm parameters and gas recipe, confirm material identity. Clean plenum and ducts on a schedule with logs. Treat certain jobs as hot work with dedicated observation.

- PPE/Response: Stage the right extinguishers: CO2 or water mist for organics; Class D media for reactive metals (magnesium, titanium). Train on the response sequence: hit E-stop, close the lid if safe to starve oxygen, close assist-gas, apply extinguisher through designed ports or after opening cautiously, evacuate, and call emergency services if flame persists.

Air Contaminants (Fumes, Gases, Particulates)

Possible Problems

- Toxic gases/vapors (e.g., hydrogen chloride from PVC; hydrogen fluoride from fluoropolymers).

- Irritants/sensitizers (e.g., formaldehyde from MDF; isocyanates from some coatings).

- Metal fumes (e.g., hexavalent chromium from stainless; zinc oxide from galvanized; nickel/copper oxides).

- Ultrafine particles and soot have deep lung penetration.

- Ozone generation with UV/high-energy processes.

- Carbon monoxide from incomplete combustion in enclosed/poorly ventilated systems.

Causes

- Cutting banned or unknown materials (PVC, PTFE, brominated FR composites, unknown plastics/coatings).

- Insufficient capture at the source; undersized fans; saturated filters; exhausted carbon beds.

- Missing make-up air is causing negative pressure and back-drafts.

- Disabled or ignored airflow and differential-pressure alarms; recirculating air inappropriately.

Control Measures

- Engineering: Capture at the source with adequate hood/enclosure flow. Use HEPA for particulates and activated carbon for VOCs; vent outdoors where regulations allow. Provide make-up air so capture velocity stays stable. Interlock cutting with airflow sensors; stop the process on failure.

- Administrative: Maintain a materials whitelist/blacklist with SDS on file. If the composition is uncertain, do not cut until verified. Track filter life by pressure drop and hours; replace on schedule. Prohibit air recirculation for high-hazard materials.

- PPE: Respirators are a last line, not a substitute for LEV. Use P100 for particulates and OV cartridges for organics during maintenance or special scenarios; fit-test and manage cartridge changeout. Do not rely on respirators for CO or oxygen-deficient atmospheres.

Electrical Hazards

Possible Problems

- Shock or electrocution during service; residual charge after shutdown.

- Arc faults and electrical fires from damaged cords or improper repairs.

- Water and electricity interaction from chiller leaks or condensation.

Causes

- High-voltage power supplies and large capacitors retain energy.

- Damaged cables, missing strain reliefs, loose grounds/bonds.

- Panels opened without lockout/tagout (LOTO); energized troubleshooting by unqualified personnel.

- Coolant leaks or condensate dripping into electronics.

Control Measures

- Engineering: Interlocked electrical panels; bleeder resistors to discharge capacitors; ground-fault protection where required. Bond machine frame, ductwork, and gas lines. Provide drip trays/leak sensors near chillers.

- Administrative: Enforce LOTO for service. Test for the absence of voltage and verify capacitor discharge before work. Limit energized diagnostics to qualified persons with a written task plan. Inspect cords/connectors routinely and log corrections.

- PPE: Electrical-rated gloves and face protection for qualified energized work; insulated tools; remove conductive jewelry and secure clothing.

Mechanical and Motion Hazards

Possible Problems

- Pinch/crush injuries at gantries, Z-tables, doors/lids.

- Entanglement in rotary attachments or rollers.

- Ejected parts propelled by assist gas; slugs dropping through and bouncing out.

- Head crashes and collisions.

Causes

- Reaching into the work area while the axes move.

- Loose clothing, dangling jewelry, and unsecured hair near rotating tools.

- Poor fixturing, small cutouts tipping, warped sheets springing free.

- Skipped dry-runs; wrong origin; missing soft limits.

Control Measures

- Engineering: Guards and interlocks on access points; safe-speed/hold-to-run modes for setup; collision detection and soft limits in controls; reliable nozzle height sensing.

- Administrative: Secure hair, remove jewelry, avoid loose sleeves. Dry-run with beam off on new or risky jobs; verify clearance. Use fixturing and tabs for parts prone to tipping.

- PPE: Safety glasses for general debris; cut-resistant gloves for handling sheet stock and sharp edges—remove gloves near rotating attachments.

High-Pressure/Compressed Gas Hazards

Possible Problems

- Regulator/hoses fail, causing uncontrolled release and hose whip.

- Oxygen enrichment accelerates fires.

- Cylinder handling injuries or valve damage, turning cylinders into projectiles.

Causes

- Mis-matched regulators, degraded hoses, improper fittings.

- Oil/grease contamination in oxygen service.

- Cylinders unsecured; caps missing in transport; rough handling.

Control Measures

- Engineering: Use pressure-rated hoses/fittings; install check valves and flashback arrestors where applicable. Match regulators to gas and pressure range; ensure components are oxygen-clean for oxygen service. Chain or strap cylinders; use caps in transport.

- Administrative: Train on cylinder change-out and leak checks (soapy water or approved method). Label gas lines and setpoints. Separate oxidizers from fuels and oils.

- PPE: Gloves and safety footwear for cylinder handling; eye protection; use carts designed for cylinders.

Thermal Hazards

Possible Problems

- Contact burns from hot parts, slats, and scrap.

- Flare-ups at the nozzle from tar/resin buildup.

- Heat stress near open industrial tables.

Causes

- Handling parts without cooldown; rushing unloading.

- Dirty protective windows/nozzles that absorb heat and ignite deposits.

- Long exposure near radiant surfaces without breaks.

Control Measures

- Engineering: Cooling conveyors or part bins on high-throughput lines. Air knives to keep windows clean and cool.

- Administrative: Allow cooldown before handling; use tongs and trays. Clean nozzles; replace protective windows on schedule. Provide work-rest cycles for high heat loads.

- PPE: Heat-resistant gloves/sleeves; long cotton garments (synthetics can melt).

Noise and Vibration

Possible Problems

- Excessive noise from blowers, pumps, and high-pressure gas; communication failures in emergencies.

- Fatigue or hearing loss over time.

Causes

- Unenclosed or poorly isolated fans/pumps; high-velocity gas jets; large open-frame cutters.

Control Measures

- Engineering: Acoustically enclose or remotely mount blowers/pumps; add silencers where compliant; isolate vibration.

- Administrative: Conduct noise surveys; post signage; rotate tasks; implement visual alarm aids.

- PPE: Hearing protection (earplugs/earmuffs) when exposure warrants.

Ergonomic and Material Handling Hazards

Possible Problems

- Back/shoulder strains from lifting sheet stock; wrist strain from awkward reaches.

- Lacerations from sharp edges and burrs.

- Repetitive strain from frequent loading/unloading.

Causes

- Manual handling of heavy or large sheets; poor workstation heights.

- Deep beds requiring reaches, cluttered layouts, and poor lighting.

- No assistive tools or team-lift practices.

Control Measures

- Engineering: Roller tables, vacuum lifters, low-friction slats, height-adjustable benches, good lighting.

- Administrative: Team-lifts with defined weight limits; organize stock at waist height; minimize carries and twists; rotate tasks.

- PPE: Cut-resistant gloves/sleeves; safety footwear; protective aprons for burrs.

Optics and Back-Reflection Hazards

Possible Problems

- Catastrophic optical damage (COD) to a fiber laser from back-reflected energy.

- Cracked protective windows or lenses ejecting shards or suddenly transmitting more energy.

- Sudden flame at the nozzle when deposits ignite.

Causes

- Cutting reflective metals (copper, brass, aluminum) without isolation, or with poor parameters.

- Resin/spatter dusting optics and increasing absorption.

- Wrong standoff; worn capacitive sensor; misfocus.

Control Measures

- Engineering: Fit optical isolators or back-reflection sensors in fiber systems; use air knives and clean, dry assist gas to keep windows clear; maintain reliable stand-off sensing.

- Administrative: Inspect and clean optics with proper wipes/solvents; never touch coated surfaces; replace protective windows proactively based on hours/conditions. Validate parameters with coupons for reflective metals.

- PPE: Eye/face protection when swapping windows (glass breakage risk); store optics in clean, labeled cases.

Software/Operational Errors

Possible Problems

- Fires/char from wrong speed/power/focus; incomplete cuts; scrap ejection.

- Head crashes; cutting outside the work envelope; motion into fixtures.

- Poor edge quality and rework.

Causes

- Unverified material profiles; wrong thickness selected; focus not updated.

- Skipped dry-runs; wrong origin or coordinate system; kerf compensation errors.

- Uncontrolled post-processor changes after software updates.

Control Measures

- Engineering: Lock down material libraries and profiles; restrict edits to qualified personnel; enable soft limits and collision detection.

- Administrative: Dry-run with beam off for new jobs, new materials, and first-article runs. Use a setup checklist: material identity, thickness, profile, focus height, nozzle, gas type/pressure, exhaust status, part tabbing/fixturing. Require a two-person sign-off for high-risk or high-value runs.

- PPE: Standard shop PPE; be ready for unexpected ejection.

Maintenance and Non-Routine Tasks

Possible Problems

- Open-beam exposure during alignment; eye/skin injury.

- Electrical shock from stored energy; energized troubleshooting.

- Inhalation of hazardous dust when changing filters; dermatitis from residues.

- Solvent exposure; scratched optics from the wrong wipes or technique.

- Coolant/biocide handling hazards.

Causes

- Interlocks defeated; panels open; no barriers; “quick checks” without procedure.

- LOTO skipped; capacitors not discharged; no test for absence of voltage.

- Filter canisters opened or dropped; dust dispersed.

- Using paper towels or dirty wipes on coated optics and over-tightening retaining rings.

- Contact with glycol/biocides without gloves/eyewash access.

Control Measures

- Engineering: Provide service modes with reduced power; use pilot beams; use temporary beam tubes or barriers during alignment. Use self-sealing filter cartridges to minimize dust release.

- Administrative: Formal LOTO and permit-to-work for open-beam or energized tasks; job hazard analyses (JHAs) for alignment, filters, and coolant service; label containers; keep SDS accessible.

- PPE: Laser eyewear for open-beam work; respirators and disposable coveralls for dusty filter tasks; chemical-resistant gloves/eye protection for solvents/coolants.

Environmental and Waste Hazards

Possible Problems

- Improper disposal of contaminated filters and dust.

- Nuisance odors or regulated emissions; community complaints; violations.

- Rooftop/duct fires spreading off equipment.

Causes

- Assuming spent filters are ordinary trash; no waste characterization.

- Saturated carbon beds; poor duct design/maintenance; no monitoring.

- Lack of spark arrestors or temperature sensors in collectors.

Control Measures

- Engineering: Use a filtration train appropriate to materials: spark arrestor → prefilter → HEPA → carbon; consider temperature sensors in collectors; design ducts to avoid dust dropouts and smolder traps.

- Administrative: Treat spent filters/dust as potentially hazardous until evaluated. Keep emissions and maintenance records; follow air-quality rules on venting vs. recirculation.

- PPE: Respiratory and skin protection when handling spent filters/duct debris; sealed bags/containers; label and date waste.

Material-Specific Red Flags

Laser cutting machines aren’t universal. Some materials are no-go; others require strict controls. Build a materials whitelist/blacklist and enforce it.

- PVC and chlorinated plastics: Release hydrogen chloride and other corrosive/toxic gases that attack lungs and machine internals. Standard practice: do not cut.

- PTFE (Teflon) and fluoropolymers: Can generate highly toxic decomposition products (including hydrogen fluoride). Avoid cutting.

- Unknown plastics/composites: Pigments, fillers, and flame retardants vary; without documentation, treat as unknown risk and decline until verified.

- Polycarbonate and some PETG grades: Strong tendency to discolor, char, and fume; extraction must be robust if processed at all.

- MDF, plywood with unknown glues: High VOC emissions; smoldering risk; never leave unattended; use strong extraction and conservative settings.

- Printed circuit boards (FR-4/CEM): Brominated FRs, copper, possibly leaded finishes. Use high-efficiency filtration; treat dust/filters as hazardous waste. Consider alternative processes.

- Stainless and high-nickel alloys: Potential for chromium/nickel compound fumes; use nitrogen assist, strong LEV, and careful waste handling.

- Galvanized steel: Zinc oxide fumes; avoid overheating and ensure ventilation.

- Reactive metals (magnesium, titanium): Combustible fines; potential Class D fires. Keep appropriate extinguishers; avoid oxygen assist.

- Foams and fabrics: Ignite easily; burn fast; demand active supervision and suppression readiness.

- Painted/coated items of unknown chemistry: Some coatings contain isocyanates/halogens; verify composition first or decline.

Building a Safety Program That Works

Safety that sticks requires four pillars: People, Procedures, Equipment, and Culture. Treat all four as essential.

People

- Competency-based onboarding:New operators must prove the basics on the actual machine: identify materials, set focus, load the right profile, perform a dry-run, respond to a staged flame, and shut down correctly. Use a sign-off checklist and keep records.

- Tiered authorizations: Differentiate between operators, setup technicians, and maintainers. Lock machine permissions accordingly (recipes, gas settings, overrides).

- Refresher training:Trigger refreshers after incidents, near misses, equipment/software changes, or new materials. Make refreshers hands-on, not just slides.

- Clear emergency roles:Pre-assign who hits the E-stop, who grabs the extinguisher, who calls emergency services, who leads the evacuation, and where to muster. Practice it.

- Coaching and feedback:Supervisors should regularly observe setups, housekeeping, and responses to alarms and provide immediate coaching.

Procedures

- SOPs aligned to reality: Write step-by-step procedures that match how work is actually done. Include visuals and torque/cleaning notes for optics.

- Pre-use checklists: Simple, visible, mandatory: material verified vs. whitelist; correct profile loaded; focus height and nozzle checked; gas type/pressure confirmed; exhaust status alarms green; extinguisher present; crumb tray empty; spark arrestor in place; post-purge enabled.

- Dry-run discipline: Beam-off passes for new jobs/materials, first articles, new fixtures, or after software updates. Require sign-off for high-risk runs.

- Material approval workflow: Don’t let “one-off” or customer-provided items bypass review. Require SDS/product data; document the decision (approved/denied/controls required).

- Maintenance plans with triggers: Base filter changes on differential pressure and hours; schedule duct/plenum cleanouts; define optics inspection intervals; test interlocks/airflow alarms monthly; record results and corrective actions.

- Permits for non-routine work: Use LOTO and permit-to-work for open-beam alignment, energized diagnostics, first-time materials, and oxygen-assisted metal jobs with elevated fire risk.

- Waste handling procedure: Bag and label spent filters; keep a log; coordinate with waste vendors for proper disposal.

- Contractor control: If third parties service the machine, they require proof of competency, alignment with your LOTO rules, and a site-specific JHA.

Equipment

- Choose enclosure and controls wisely: For general use, prefer Class 1 fully enclosed machines. Fiber laser cutting systems on reflective metals require back-reflection monitoring and manufacturer-validated cut data.

- Ventilation that fits the work: Size LEV for the worst case. Use airflow sensors and alarms interlocked to beam enable. Include spark arrestors for flammables and post-purge timers. Provide make-up air so capture stays stable.

- Fire detection/suppression: Optical/thermal detectors in the cabinet; automatic suppression for high-risk duty cycles or materials. Temperature monitoring on dust collectors.

- Service-friendly design: Easy access to optics and filters; self-sealing filter cartridges; drip protection around electronics; clear routing of gas/electrical lines. Keep spares: protective windows, lenses, nozzles, fuses, hoses, and filters.

- Right extinguishers, right place: CO2 or water mist near the machine for organics; Class D media where reactive metals are possible. Mount within quick reach and inspect monthly.

- Ergonomic aids: Sheet lifters, roller stands, parts trays, adjustable tables, and bright task lighting.

- Sensing and logging: Where possible, log airflow DP, interlock status, gas usage, and fault codes. Use trends to spot problems before they turn into incidents.

Culture

- Housekeeping as a habit: Clean beds, empty crumb trays, clear plenum entries, wipe nozzles, date filters. Make housekeeping a scheduled, checked task with ownership.

- Near-miss gold mining: Encourage reporting of “almost” events and minor anomalies (e.g., brief sustained flame, unusual smell, falling airflow). Reward reporting, not silence. Fix systems, not blame people.

- No shortcuts: Never trade safety controls for throughput. Ban “temporary” interlock bypasses, unattended flammable jobs, and cutting unknowns.

- Visible leadership: Leaders budget for filters, spare optics, extinguishers, and downtime to fix real problems. They ask to see checklists and maintenance logs and treat them seriously.

- Standardized handoffs: Shift changes include machine status, filter DP, recent anomalies, pending maintenance, and what job is next.

Summary

Laser cutting machines are compact factories: high-energy light, hot work, moving parts, high-pressure gases, and extraction systems in one box. They reward discipline and punish sloppiness. Most incidents trace back to the same themes: unknown materials, weak or failed ventilation, dirty optics, oxygen misuse, debris accumulation, rushed setups, and bypassed interlocks.

Control the risk by stacking layers:

- Eliminate/substitute: Ban PVC, PTFE, and unknowns; choose safer materials; prefer nitrogen or air where oxygen adds unjustified risk.

- Engineer it out: Keep the enclosure closed and interlocked; size and monitor extraction; add spark arrestors, fire detection, and post-purge; protect fiber sources from back-reflection; design gas systems with correct, clean components.

- Manage with procedures: Lock material profiles; use pre-use checklists and beam-off dry-runs; approve materials via SDS; run LOTO and permits for non-routine work; maintain optics and filters on schedule with logs; handle waste properly.

- Backstop with PPE: Laser eyewear for open-beam tasks; safety glasses in the shop; respirators for maintenance or special cases; heat and cut protection; hearing protection where needed.

- Build the culture: Housekeeping pride, near-miss reporting, leadership that backs safety with time and money, and zero tolerance for “just this once” shortcuts.

Do that consistently, and the machine becomes what you want it to be: precise, productive, and boring from a safety standpoint—a tool that never surprises you.

Get Laser Cutting Solutions

When safety and throughput both matter, choose a laser cutting package engineered for hazard control from the start. Maxcool CNC designs Class 1, fully enclosed laser cutting systems with fail-safe interlocks, wavelength-rated viewing windows, and real-time back-reflection monitoring/optical isolation to protect the laser source when processing reflective metals. We pair the machine with right-sized local exhaust ventilation: HEPA for ultrafine particulates, activated carbon for VOCs, airflow sensors tied to auto-shutdown, spark arrestors, and programmable post-purge to clear embers after cutting. For higher-risk duty cycles, add in-cabinet thermal/optical fire detection and automatic suppression.

Assist-gas packages are built for reliability and control: oxygen-clean components, pressure-rated hoses, leak-tested regulators, and clear line labeling, plus pressure/flow monitoring at the nozzle. On-head safety features include capacitive height sensing, anti-collision, and quick-swap protective windows. Software locks proven process recipes, enforces material whitelists, and guides operators with pre-use checklists and beam-off dry-runs.

A safe shop runs on discipline, so every solution can include commissioning, operator/maintainer training, SOP and LOTO templates, and first-article validation. Preventive-maintenance plans cover optics care, airflow, and interlock audits, filter changes, and spare-parts kits—along with documentation to support emissions and waste handling for used filters and metal fines. Ready to turn risk into predictable, high-quality output? Ask AccTek for a site assessment and a tailored, safety-first laser cutting solution.