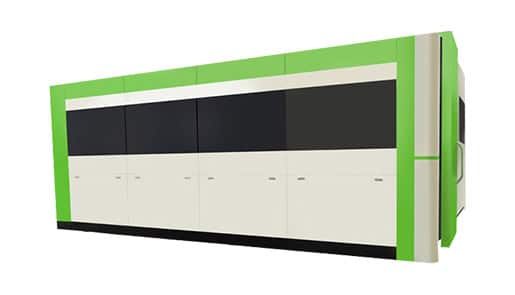

The Fully Enclosed Fiber Laser Cutting Machine with Exchange Platform is a high-performance, industrial-grade solution designed for safe, efficient, and precise metal cutting operations. This machine features a fully enclosed structure that enhances operator safety by containing laser radiation, smoke, and dust while maintaining a clean working area. The enclosed design also improves overall cutting stability by reducing environmental interference.

One of the machine’s key features is its dual exchange platform, which significantly boosts productivity. While one working table is actively cutting, the second table can be loaded or unloaded with materials, minimizing downtime between cycles. This efficient material handling system makes the machine ideal for high-volume production requiring high speed and continuous operation. The platform exchange is fast, automated, and precisely aligned, ensuring smooth transitions and consistent cutting performance.

MC3015FBC is particularly suited for cutting various metals, including carbon steel, stainless steel, aluminum, copper, and brass, with high precision and clean edges. The combination of safety, speed, and accuracy makes the fully enclosed fiber laser cutting machine with exchange platform an excellent choice for modern manufacturing facilities that prioritize efficiency and workplace safety.

4 reviews for Fully Enclosed Fiber Laser Cutting Machine with Exchange Platform

Mason –

We are very satisfied with the machine. It cuts consistently well and has improved our production capacity by 30%.

Evelyn –

The machine offers amazing precision for detailed work. It has increased our output and reduced our production time.

Ella –

The machine is reliable and easy to use. It’s helped reduce costs and improve our production quality.

Benjamin –

Great machine! It works flawlessly on a variety of materials and produces a smooth, clean cut every time.