Types of Laser Welding Machines and Their Risks

CO2 Lasers

Risks associated with CO2 Lasers:

- While CO2 lasers are effective for heavy-duty welding, they also present specific safety hazards. The most immediate risk comes from the laser radiation itself. The infrared radiation produced by CO2 lasers is invisible to the human eye, and direct exposure can cause severe eye damage or blindness. Operators must wear proper laser safety goggles designed to block infrared wavelengths to protect their eyes.

- Additionally, CO2 lasers generate high heat, increasing the risk of fire, especially when welding flammable materials. The high temperatures involved in the welding process can cause burns or other injuries if not handled properly. CO2 lasers are typically housed in large machines that require proper maintenance and protective enclosures to prevent accidental exposure to the laser beam. Furthermore, CO2 lasers can produce toxic fumes depending on the materials being welded, which necessitates the use of effective ventilation systems to protect workers from inhaling hazardous gases.

Fiber Lasers

Risks associated with Fiber Lasers:

- Despite their many advantages, fiber lasers carry several risks. First and foremost, fiber lasers can emit highly concentrated and focused beams of light that can be hazardous to the eyes, especially due to the shorter wavelength. Fiber lasers require careful handling and the use of proper personal protective equipment (PPE), including eyewear specifically designed to block the laser’s wavelength.

- Another significant risk of fiber lasers is the potential for burns or skin injuries. Given the laser’s ability to focus on very small spots with high intensity, the beam can easily cause localized burns on the skin or other surfaces if direct exposure occurs. Additionally, fiber lasers can be prone to overheating in certain conditions, leading to risks of fires or equipment malfunction.

Nd:YAG Lasers

Risks associated with Nd:YAG Lasers:

- Nd:YAG lasers present unique risks due to their high intensity and potential for focused energy. One of the key dangers is direct exposure to the laser beam, which can cause serious eye damage or burns. As with other types of lasers, operators must wear specialized safety goggles to block out the specific wavelength of the Nd:YAG laser.

- Another concern with Nd:YAG lasers is the high temperatures they generate during welding. These lasers are particularly capable of creating deep penetration welds, which can lead to intense heat buildup and potential burns or fires if safety precautions are not taken. The risks of electrical shock are also present with Nd:YAG lasers due to the high-voltage systems that power the machines, making it essential for operators to be trained in safely handling these machines.

- Furthermore, Nd:YAG lasers can also generate harmful gases and fumes during the welding process. These fumes may contain toxic elements depending on the materials being welded, making it crucial to implement proper ventilation and exhaust systems to reduce the risk of respiratory issues among workers.

Laser Beam Hazards and Safety Measures

Eye Protection

The most significant hazard associated with laser beams is the potential damage to the eyes. Laser radiation can cause permanent eye injuries, including blindness, depending on the power of the laser, the wavelength of the emitted light, and the duration of exposure. The primary risk is from direct exposure to the laser beam, but even reflected or scattered light can cause serious eye damage.

- Risks to Eye Health:

- Laser beams, particularly those from high-power lasers such as CO2 and fiber lasers, can damage the retina, cornea, or lens of the eye. The severity of the injury depends on several factors, including the wavelength of the laser light and the intensity of exposure. For instance, infrared lasers, which are commonly used in welding, are invisible to the human eye but are still capable of causing severe retinal burns or irreversible damage.

- Even low-power lasers can cause temporary visual disturbances, but high-power lasers present a much greater risk, potentially leading to permanent vision loss. The effects may not be immediately noticeable, as laser-induced eye injuries can take time to manifest, making protective measures even more critical.

- Safety Measures for Eye Protection:

- To mitigate these risks, laser welding operators must always wear appropriate eye protection that is specifically designed to block the wavelength of the laser being used. Laser safety goggles or face shields with optical filters are the most common types of protective eyewear. These goggles are designed to absorb or reflect the dangerous wavelengths while allowing the operator to see the work area clearly. It’s essential to ensure that the eyewear is in good condition, free from scratches or other damage that could compromise its effectiveness.

- Moreover, operators should avoid looking directly at the laser source, even when the equipment is in operation, and never attempt to bypass safety mechanisms that prevent direct exposure to the laser beam. For areas with multiple operators or anyone near the work area, additional protective measures, such as laser barriers or protective curtains, should be installed to prevent accidental exposure.

Skin Protection

While eye protection is often emphasized, the risk of skin injury from laser welding is equally important. Laser beams, particularly those with high intensity, can cause severe skin burns upon direct or reflected contact. The intense heat generated by the laser can rapidly raise the temperature of the skin, leading to first, second, or even third-degree burns.

- Risks to Skin Health:

- Laser radiation can cause skin damage similarly to the way sunlight causes sunburn, except that the energy from laser beams is far more concentrated. High-intensity lasers can quickly raise the skin temperature to the point where it is effectively “cooked,” leading to painful burns, blistering, and potential long-term scarring. In addition to the direct risks posed by the laser beam, skin can also be damaged from the intense heat generated during the welding process. This can be particularly dangerous in scenarios where the operator is working in proximity to the welding point.

- Certain materials, when subjected to laser welding, can reflect laser light in unpredictable directions, increasing the risk of skin exposure. This is especially true with highly reflective metals, which can scatter the laser energy across the surrounding area. Therefore, both direct and indirect exposure to the laser beam must be carefully considered and managed.

- Safety Measures for Skin Protection:

- To protect the skin from laser beam hazards, operators must wear specialized clothing that covers exposed areas of the body. Protective garments made of flame-retardant or heat-resistant materials are essential to prevent burns caused by accidental exposure to the laser or the heat generated during welding. In addition to gloves and aprons, full-body suits or jackets may be necessary, particularly in high-risk environments where operators are working in proximity to the laser source.

Fire and Explosion Hazards

Fire Prevention

One of the most significant risks in laser welding is the potential for fire. The laser beam itself generates extremely high temperatures at the point of contact with the material, which can easily ignite flammable substances nearby. This is especially true when welding materials such as plastics, wood, or other combustible materials, which can catch fire from the heat of the laser. Even metals that are not inherently flammable can become hazardous if they are coated with or mixed with flammable substances, such as oil, grease, or solvents.

- Fire Risk Factors:

- The laser’s focused energy is concentrated in a very small area, generating intense heat. When this heat is transferred to the workpiece, it can rapidly elevate the temperature of nearby materials, leading to the risk of fire, especially when proper precautions are not taken. Additionally, the welding process can cause sparks or molten material to fly off the workpiece, which could ignite nearby combustible materials or surfaces.

- Another fire hazard arises from the fumes and gases released during welding. Certain materials, particularly those with coatings or finishes, can release volatile compounds that are flammable. The presence of such gases in the air, when combined with high temperatures, creates a risk of ignition.

- Fire Prevention Measures:

- To prevent fires during laser welding, it is critical to ensure that the workspace is free from any flammable materials. This includes cleaning the area of any combustible dust, oils, solvents, or papers that may have accumulated in or around the welding station. Ensuring that the materials being welded are free from contaminants that could catch fire is also essential. Regular cleaning and maintenance of the machine are necessary to ensure that no combustible material is trapped in the machine’s components or equipment.

- Furthermore, laser welding machines should be equipped with fire-resistant barriers or shields to contain sparks and molten material. These barriers prevent any materials from being ignited by the heat or sparks produced during the welding process. It is also advisable to have automatic fire suppression systems in place, such as sprinklers or CO2 fire extinguishing systems, especially in larger facilities where the fire risk may be more significant. Operators should also be trained in the proper use of fire extinguishers and emergency procedures in the event of a fire.

Ventilation to Prevent Explosion

While fire hazards are an obvious concern, laser welding also presents significant explosion risks, primarily due to the fumes and gases produced during the welding process. Many materials release hazardous gases, including volatile organic compounds (VOCs), when heated by the laser. These gases can accumulate in the workspace, and if they reach a certain concentration, they can ignite or even cause an explosion.

- Explosion Risk Factors:

- The type of material being welded plays a significant role in determining the risk of explosion. For example, welding metals that contain oils or plastics that release flammable vapors increases the likelihood of creating an explosive atmosphere. These gases can be ignited by heat, sparks, or even the laser itself, leading to a potentially catastrophic explosion.

- Another contributing factor is the buildup of combustible dust or fumes within an enclosed environment. If ventilation is insufficient, these particles and gases can accumulate to dangerous levels. A spark or small ignition source could then cause an explosion, particularly in areas where there is poor airflow or inadequate extraction systems.

- Ventilation Safety Measures:

- To mitigate the risk of explosions, proper ventilation is one of the most important safety precautions in any laser welding operation. Adequate ventilation systems should be installed to ensure that any hazardous gases, fumes, or particles are effectively removed from the workspace. Fume extractors, dust collectors, and industrial-grade ventilation systems should be used to maintain a safe air quality level.

- The ventilation system must be designed to handle the specific fumes and gases produced during welding. For instance, some materials may release particularly harmful or flammable fumes, requiring more specialized filtration or extraction systems. The ventilation system should be regularly inspected and maintained to ensure that it remains effective in removing these potentially dangerous gases.

Personal Protective Equipment (PPE)

Laser Safety Glasses

One of the most significant hazards in laser welding is the potential for eye damage due to exposure to laser radiation. Laser beams, especially those from high-powered lasers like CO2 and fiber lasers, can cause permanent damage to the eyes, including retinal burns or even blindness, if there is direct exposure. The high intensity of laser light, which is often invisible to the human eye (particularly in infrared wavelengths), makes it all the more dangerous.

- Risks to Eye Health: Laser radiation can damage the delicate structures of the eye, with the retina being particularly vulnerable. The severity of the injury depends on several factors, including the laser’s power, the wavelength of the light, and the exposure duration. While the eye can handle exposure to visible light, the infrared radiation emitted by lasers used in welding can penetrate the eye’s natural defenses, causing permanent damage that may not be immediately noticeable.

- Safety Measures for Eye Protection: To prevent eye injuries, operators must wear laser safety glasses or face shields designed to filter out harmful laser wavelengths. These glasses are specifically engineered to block the type of radiation emitted by the laser used in the welding process, ensuring that only safe levels of light reach the eyes. The glasses should be chosen based on the laser’s wavelength, and it is essential to ensure that they fit properly, covering the eyes completely and providing full protection. It is also important to inspect the glasses regularly for damage, as any cracks or scratches can compromise their effectiveness. In addition to personal eye protection, operators should ensure that the work area is equipped with safety enclosures or barriers to prevent accidental exposure to the laser beam.

Heat-Resistant Clothing

The intense heat generated by the laser during welding poses a significant risk to the operator’s skin. When the laser beam strikes the material, it causes localized heating, which can generate molten material, sparks, or debris that can easily burn the skin. Even if the operator is not directly in contact with the laser beam, they can still be exposed to the heat radiating from the welding process.

- Risks to Skin Health: Exposure to molten metal, hot sparks, or intense heat can lead to first-degree burns (redness and irritation), second-degree burns (blisters), or even third-degree burns (deep tissue damage). Additionally, the heat from the laser can cause discomfort, dehydration, or heat stress if the operator is not adequately protected.

- Safety Measures for Skin Protection: To protect against these risks, operators must wear heat-resistant clothing made from materials such as flame-retardant cotton, leather, or specialized high-temperature fabrics. These garments should cover the entire body, including gloves, aprons, and full-body suits, to ensure there is no exposed skin. Heat-resistant gloves protect the hands from molten metal and hot surfaces, while jackets or full-body suits provide additional protection from burns. The clothing should be durable and able to withstand the physical stresses of welding, including exposure to high temperatures and mechanical impacts from flying debris. It is also essential to regularly check for wear and tear on the protective clothing and replace it as necessary to maintain optimal protection.

Respiratory Protection

Laser welding produces fumes and gases as the materials being welded are heated to high temperatures. These fumes may contain harmful particles, vapors, and chemicals that can be hazardous when inhaled. Depending on the materials being welded (such as metals with coatings, plastics, or other chemicals), these fumes can be toxic or carcinogenic, leading to long-term respiratory problems or even poisoning.

- Risks to Respiratory Health: The welding process often generates fumes that can irritate the respiratory system, leading to symptoms such as coughing, shortness of breath, or a sore throat. Over prolonged exposure, these fumes can cause more severe respiratory conditions, such as lung damage, asthma, or even cancer. For instance, materials like galvanized steel can release zinc oxide fumes, which are particularly hazardous if inhaled over extended periods.

- Safety Measures for Respiratory Protection: To protect against inhalation of harmful fumes, operators must wear appropriate respiratory protection. This typically includes a half-mask or full-face respirator equipped with filters designed to trap harmful particles and gases. In high-risk environments, powered air-purifying respirators (PAPRs) may be necessary to provide clean, filtered air. In addition to personal respirators, the workspace should be equipped with a fume extraction system that captures and removes harmful fumes directly from the welding area. The ventilation system should be properly maintained and regularly inspected to ensure it operates efficiently. It is also advisable to monitor air quality using sensors to detect the presence of toxic gases and ensure that the levels remain below recommended safety limits.

Hearing Protection

While not as commonly associated with laser welding, hearing protection is also an important aspect of safety, particularly in environments where multiple machines are in use. Although laser welding is not as noisy as some other welding techniques, the noise levels generated by the equipment and the impact of molten material can still exceed safe hearing thresholds, leading to potential hearing damage over time.

- Risks to Hearing Health: Exposure to loud noises in a welding environment, especially in confined spaces or areas with high noise levels, can cause noise-induced hearing loss (NIHL). The decibel levels generated by welding machines, ventilation systems, and mechanical equipment can cause permanent damage to the inner ear if appropriate hearing protection is not used.

- Safety Measures for Hearing Protection: To protect against hearing damage, operators should wear hearing protection, such as earplugs or earmuffs, whenever they are working in noisy environments. The level of protection required depends on the noise levels present in the workspace, and it is important to ensure that the protection is comfortable and provides adequate sound attenuation. Regular monitoring of the workplace’s noise levels can help determine the need for hearing protection, and employees should be encouraged to use it consistently to prevent long-term hearing loss.

Fume and Gas Hazards

Fume Extraction Systems

Ventilation

Proper ventilation is another essential element of controlling fume and gas hazards in a laser welding environment. Even with the best fume extraction systems in place, adequate ventilation is necessary to prevent the buildup of harmful gases in the workspace. Without proper ventilation, hazardous fumes and gases can accumulate to dangerous levels, leading to potential health risks such as dizziness, nausea, headaches, or even more severe effects such as long-term lung diseases.

- Ventilation Design:

- To effectively control fume and gas exposure, the workspace should have a well-designed general ventilation system in addition to localized fume extraction. This includes ensuring that the welding area is adequately ventilated with an appropriate exchange of fresh air to dilute any airborne contaminants. A combination of supply and exhaust ventilation should be used to draw in fresh air while removing contaminated air.

- In enclosed environments, it may be necessary to install a dedicated industrial ventilation system to maintain airflow and prevent dangerous concentrations of gases. These systems should be capable of handling the specific types of fumes generated by the materials being welded. For example, when working with materials that release particularly hazardous fumes, such as lead-based coatings, additional ventilation measures may be required to ensure the safety of workers.

- Air Monitoring:

- In addition to physical ventilation, air monitoring systems can be used to detect the presence of harmful gases, such as carbon monoxide or ozone, in the air. These monitoring systems can provide real-time data on air quality and alert operators to dangerous conditions. In the event of elevated concentrations of hazardous gases, workers can take immediate action by adjusting ventilation systems, increasing airflow, or evacuating the area if necessary.

Material Safety Data Sheets (MSDS)

Maintenance and Inspection

Regular Inspection

Regular inspection is the cornerstone of maintaining a safe and effective laser welding system. These inspections help identify potential issues before they develop into serious problems, ensuring the machine continues to operate within safe parameters. The frequency and scope of inspections may vary depending on the machine’s usage, the materials being welded, and the manufacturer’s guidelines. However, certain key components require consistent attention to ensure that the laser welding machine remains safe and functional.

- Key Components to Inspect:

- Laser Optics: The laser optics, including mirrors, lenses, and beam delivery systems, need to be inspected frequently to ensure they are clean and free from scratches or damage. Contaminants, such as dust or dirt, can significantly reduce the beam quality, affecting the accuracy and efficiency of the welding process. Damaged optics can also redirect or scatter the laser beam, posing safety hazards to the operator. Regular cleaning with appropriate methods is necessary, and any signs of wear or damage should be addressed immediately.

- Laser Source: The laser source is the heart of the system and requires regular checks to ensure it is functioning correctly. Regularly inspecting the power levels, calibration, and alignment of the laser is critical to avoid inconsistent welding results or machine malfunctions. Monitoring the cooling system that prevents the laser from overheating is also vital, as overheating can damage the system or lead to system failure.

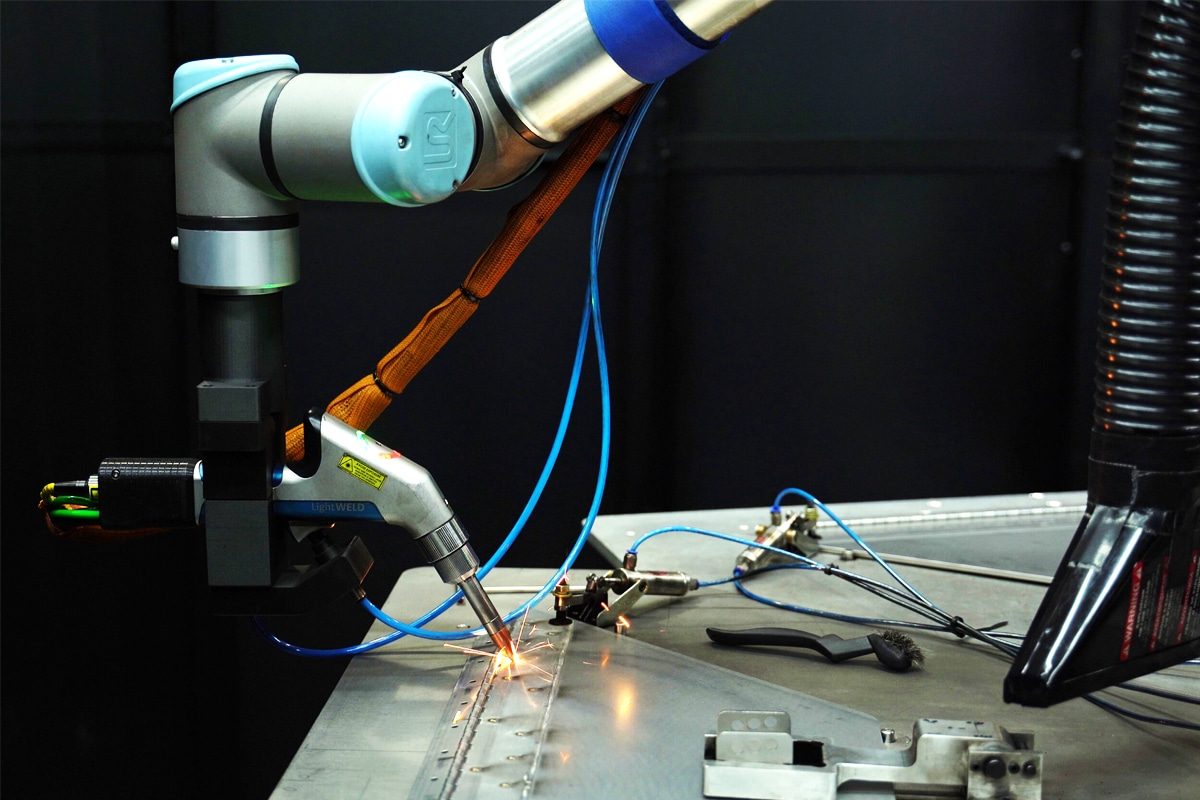

- Mechanical Components: The moving parts of the laser welding machine, such as robotic arms, actuators, and motion systems, should be inspected regularly for any signs of wear, corrosion, or misalignment. Malfunctions in these components can lead to mispositioned welds or mechanical failures during operation. Lubrication of moving parts is also crucial to prevent friction damage.

- Safety Features: Safety systems, such as interlocks, emergency stops, and protective enclosures, should be regularly tested to ensure they are operational. Any malfunction in these safety mechanisms can expose the operator to significant risks, such as laser exposure or accidental machine operation. Regular testing of these features ensures that, in case of an emergency, the system will respond effectively.

- Electrical Systems: Electrical connections, cables, and components must be regularly checked for wear, corrosion, or loose connections that could lead to electrical failures or even fires. Ensuring proper grounding and the integrity of power supplies is critical to preventing electrical hazards.

- Fume and Ventilation Systems: Since laser welding produces fumes and gases, ensuring that the fume extraction and ventilation systems are functioning properly is crucial. These systems should be checked regularly to ensure that they are capturing harmful fumes efficiently and maintaining safe air quality in the workspace.

- Inspection Frequency:

- While specific inspection intervals may vary, the general guideline is to perform a comprehensive inspection of the laser welding machine regularly, typically once a week or after every shift, depending on the intensity of use. In addition, a more detailed inspection should be conducted at least once a month or after extended periods of use, ensuring that any issues are addressed promptly before they escalate.

Preventive Maintenance

Preventive maintenance goes beyond simple inspections and focuses on proactively addressing potential issues before they can impact machine performance or safety. Preventive maintenance aims to identify areas where wear and tear may lead to breakdowns and fix them before they cause costly or hazardous failures. A well-structured preventive maintenance program ensures that all components of the laser welding machine continue to function optimally, improving both the safety and efficiency of the operation.

- Key Preventive Maintenance Practices:

- Cleaning and Calibration: Regularly cleaning the optics and calibrating the laser beam ensures consistent beam quality and welding results. Cleaning should be done with appropriate non-abrasive materials to avoid damaging sensitive optics. Calibration ensures that the beam is properly aligned and functioning at the correct power levels, reducing the risk of errors in the welding process.

- Component Lubrication: The moving parts of the machine should be lubricated regularly to reduce friction, prevent wear, and ensure smooth operation. Using the correct type of lubricant for each component is essential to avoid damage or performance issues. For example, robotics and actuators require a different type of lubrication than electrical components or beam delivery systems.

- Replacing Worn Parts: Over time, parts of the laser welding machine will naturally experience wear and tear. Components such as laser tubes, filters, lenses, and seals may degrade with use. Preventive maintenance includes regularly replacing worn-out parts based on usage intervals recommended by the manufacturer. This helps prevent more serious malfunctions and extends the overall lifespan of the machine.

- Cooling System Maintenance: The cooling system is crucial for maintaining the optimal temperature of the laser source. Preventive maintenance of this system involves regularly checking coolant levels, cleaning coolant filters, and ensuring that the heat exchange system is functioning properly. A malfunctioning cooling system can lead to overheating, damaging the laser source and other critical components.

- Electrical and Safety System Checks: Preventive maintenance should also involve checking the electrical wiring and safety systems. Ensuring that all electrical connections are secure and free from damage, testing emergency stop mechanisms, and verifying the functionality of laser enclosures or protective shields are all essential steps in preventing electrical or safety-related issues.

- Fume Extraction and Ventilation Maintenance: Fume extraction systems and ventilation systems should undergo regular maintenance to ensure they are working efficiently. This includes checking the filters and replacing them when needed, inspecting ducts for blockages or leaks, and ensuring that the airflow is sufficient to keep the workspace free of hazardous fumes.

- Establishing Preventive Maintenance Schedules:

- A preventive maintenance schedule should be developed based on the manufacturer’s recommendations and the specific needs of the welding operation. This schedule should include detailed procedures, intervals, and personnel responsible for performing the maintenance tasks. By following this schedule, operators can address potential issues before they cause equipment downtime or safety incidents.

Operator Training

Safety Protocols

Safety protocols are the foundation of operator training in laser welding. These protocols outline the standard operating procedures that operators must follow to minimize the risk of accidents and injuries. Training operators in these protocols is crucial, as even small lapses in safety can lead to significant hazards, including laser exposure, burns, electrical shocks, fires, or inhalation of harmful fumes. The following are key aspects of the safety procedures:

- Personal Protective Equipment (PPE): Operators must be trained on the proper use of PPE, including laser safety glasses, heat-resistant clothing, gloves, respiratory protection, and hearing protection. They need to understand the importance of wearing the right PPE for the specific laser welding machine they are operating and the materials being welded.

- Safe Operation of the Laser Welding Machine: Operators must be trained in the proper setup, calibration, and operation of the laser welding system. This includes understanding how to adjust the laser settings, the safe handling of materials, and ensuring that the system is correctly aligned before starting the welding process. Operators should also be familiar with machine controls, including emergency stop buttons, safety interlocks, and safety shields.

- Laser Beam Safety: Operators should be taught the dangers of laser radiation and how to avoid exposure. This includes understanding the potential harm from direct or reflected laser beams and the importance of maintaining a safe distance from the laser source, using protective barriers, and following strict guidelines for working near the laser.

- Workplace Safety: Operators need to be aware of the general safety measures in the welding area, such as keeping the workspace clean and free from flammable materials, ensuring that ventilation and fume extraction systems are functioning properly, and maintaining a safe distance from others when operating the machine. They should also be trained to recognize potential hazards, such as overheated equipment or exposed wiring, and take appropriate action.

- Handling Hazardous Materials: Many materials used in laser welding can release toxic fumes or gases, so operators must be educated about the materials they are working with, including potential chemical hazards. They should be trained in handling and disposing of materials safely and in accordance with the Material Safety Data Sheets (MSDS).

Emergency Procedures

Despite taking every precaution, accidents can still happen, and operators must be prepared to respond effectively to any emergencies that may arise during laser welding operations. Well-established emergency procedures must be part of the operator training process to ensure quick, decisive action in the event of a fire, electrical malfunction, laser exposure, or other incidents. The following are the key elements of the emergency procedure:

- Fire and Explosion Response: Operators must be trained on how to respond to fires or explosions. This includes knowing the location of fire extinguishers, how to use them effectively, and understanding the specific types of fires that may occur (e.g., electrical, chemical, or material fires). Additionally, operators should be aware of the procedure for evacuating the area in the event of a fire or explosion, and they should be familiar with the facility’s emergency evacuation routes.

- Laser Exposure Incidents: In the event of accidental laser exposure, operators must know how to respond immediately to minimize damage. This may include flushing the eyes with water in case of eye exposure, seeking medical attention for burns or skin exposure, and reporting the incident to supervisors. Operators should be trained to recognize the symptoms of laser exposure and know when to seek emergency medical assistance.

- Electrical Failures and Shock: Operators should be aware of the dangers of electrical shock, especially when working with high-voltage components in the welding machine. They must be trained in how to safely shut down the machine in case of electrical failure, how to handle electrical emergencies, and how to provide first aid in case of shock, including when to call emergency medical personnel.

- Fume and Gas Exposure: In the event of harmful fume or gas exposure, operators need to know the signs of poisoning or respiratory distress. They should be familiar with the location of ventilation and fume extraction systems and how to quickly turn them on or adjust settings to improve air quality. In more severe cases, operators should be trained in how to perform first aid and when to seek medical help.

Ongoing Training

Laser welding technology is constantly evolving, with new advancements in laser types, materials, and safety measures being introduced regularly. As such, it is crucial that operator training does not end after the initial certification but continues throughout the operator’s career. Ongoing training ensures that operators remain up-to-date on the latest safety procedures, technologies, and best practices, enabling them to work safely and efficiently in a constantly changing environment. The following is the ongoing training content:

- Refresher Courses: Regular refresher training sessions should be scheduled to review safety protocols, emergency procedures, and any updates to laser welding techniques. These sessions can serve as a reminder of safe practices and help prevent complacency, ensuring that safety remains a top priority.

- Training on New Technology: As new laser welding systems, tools, or safety technologies are introduced, operators must be trained to use these innovations effectively. This might include training on new laser types, such as fiber lasers, or updates to fume extraction and ventilation systems. Ongoing training ensures that operators are prepared to handle new technology without compromising safety.

- Simulation and Hands-On Training: In addition to classroom-style training, hands-on experience is critical for operators to fully understand how to respond in real-world situations. Simulation-based training can be used to practice emergency scenarios, such as laser exposure, fire outbreaks, or electrical failures. This gives operators the confidence and skills to act quickly and decisively during actual emergencies.

- Safety Audits and Feedback: Ongoing training should also include regular safety audits, during which operators are evaluated on their adherence to safety protocols. These audits provide valuable feedback to help identify any areas where additional training is needed. Continuous feedback helps improve performance and encourages operators to remain vigilant in maintaining safety standards.

Maintaining Safe Working Environments

Workplace Organization

Proper workplace organization is a key factor in maintaining a safe laser welding environment. A well-organized workspace reduces the risk of accidents by keeping hazards at bay, improving efficiency, and ensuring that safety protocols can be followed easily. When the workspace is cluttered or disorganized, it becomes more difficult to identify and address potential hazards, and it increases the likelihood of accidents, such as tripping, exposure to hazardous materials, or accidental laser exposure. The following are key elements of workplace organization:

- Clear Work Zones: Designating specific work zones for laser welding operations is essential. The laser welding area should be clearly marked, with boundaries that restrict access to unauthorized personnel. This helps reduce the risk of accidental exposure to the laser beam or other hazards. Operators should have sufficient space around the machine to maneuver safely and access tools or materials without obstruction.

- Proper Storage of Tools and Materials: Tools, materials, and PPE should always be stored in designated, easily accessible areas. This prevents unnecessary movement in the work area and reduces the chances of hazardous materials being left out in the open. Additionally, storing materials properly helps minimize the risk of fire or explosion, especially when dealing with flammable substances. For example, gas cylinders and other chemicals should be stored in well-ventilated, fire-resistant cabinets away from the welding area.

- Clear Signage and Labeling: All safety signs, emergency exits, and important equipment (such as fire extinguishers or emergency stops) should be clearly visible and accessible. This ensures that operators can quickly locate critical safety features during an emergency and that all personnel are aware of potential hazards. Labels indicating the risks associated with materials or equipment should be prominently displayed to prevent improper handling or misuse.

- Organization of Electrical and Power Sources: Electrical panels, power switches, and other essential controls should be clearly labeled and easily accessible in case of an emergency. Cables should be organized and secured to avoid tripping hazards or damage to wires, which could lead to electrical faults or fire risks.

Regular Maintenance and Inspections

Regular maintenance and inspections are critical for keeping the laser welding machine and associated equipment in safe working order. Over time, equipment can wear down, and the risk of malfunction increases. Without a systematic approach to maintenance and inspections, operators may find themselves working with faulty machinery, which increases the likelihood of accidents, injuries, and downtime. The following are key aspects of maintenance and inspection:

- Machine Inspections: Routine inspections should be performed to identify any signs of wear or damage to the laser welding machine and its components. Key components to check include the laser optics, cooling systems, electrical connections, and safety mechanisms. Ensuring that all components are properly calibrated and in good working condition is vital for maintaining safe operations. Any issues identified during inspections should be addressed immediately to prevent more severe problems from arising.

- Fume Extraction Systems and Ventilation: The fume extraction system and ventilation must be checked regularly to ensure they are functioning effectively. Blockages, damaged filters, or inadequate airflow can result in the accumulation of harmful fumes and gases in the workspace, posing a significant health risk to operators. These systems should be cleaned, filters replaced, and air ducts inspected for any obstructions. A regular maintenance schedule will help ensure that these systems can handle the amount of fume generated during welding operations.

- Electrical and Mechanical Maintenance: The electrical and mechanical components of the machine should be regularly checked for damage or wear. This includes inspecting power sources, control panels, wiring, and robotic arms or actuators. Electrical malfunctions or mechanical failures could lead to hazards such as electrical shocks, fires, or even machine breakdowns that disrupt operations. Preventive maintenance, such as cleaning, lubrication, and component replacement, ensures the longevity of the equipment and helps avoid safety-related malfunctions.

- Calibration and Alignment: Regularly calibrating the laser and aligning the optics ensures that the machine is operating at its optimal efficiency. Misaligned optics can result in poor weld quality, while inaccurate calibration can lead to safety issues, such as accidental laser exposure or material damage. Calibration should be performed according to the manufacturer’s recommendations or after extended use to ensure that the laser beam is focused and correctly positioned.

Safe Handling of Materials

The materials being welded often represent a significant hazard in laser welding operations. Whether it’s the potential for fire, the release of toxic fumes, or the handling of heavy or delicate materials, safe material handling is essential to maintaining a secure work environment. Proper material handling minimizes the risk of accidents and ensures the integrity of the weld, leading to better overall outcomes for the welding process. The following are key aspects of safe material handling:

- Correct Storage of Materials: As mentioned earlier, materials must be stored in designated areas that minimize risks such as fire or chemical reactions. Flammable materials should be kept away from the laser welding station, and chemicals or coatings that produce hazardous fumes when heated should be stored and handled according to their MSDS. Proper labeling and categorization of materials ensure that workers can easily identify hazardous substances and handle them appropriately.

- Handling Hazardous Materials: Many metals and materials used in laser welding can release toxic fumes when heated. For instance, metals like lead or zinc can emit hazardous gases when exposed to high temperatures. Operators must be trained to handle these materials safely and use the appropriate PPE. When working with such materials, operators should also ensure that the fume extraction systems are operational and effective. In addition, combustible materials should be handled with care to prevent ignition from sparks or molten metal generated during the welding process.

- Transporting and Positioning Materials: When transporting or positioning materials, care should be taken to ensure that they are stable and securely placed. Materials should be lifted and moved using appropriate equipment, such as cranes, hoists, or trolleys, to avoid physical strain or accidents. Improperly secured or unstable materials can result in injury to operators or others in the area. Operators should also be mindful of the possibility of sharp edges or hot surfaces when handling materials after welding, as these can cause burns or cuts.

- Waste Disposal: Proper disposal of waste materials, such as metal scraps, debris, and spent filters, is critical to maintaining a safe working environment. Waste should be segregated based on material type and disposed of according to safety guidelines. Regular disposal of hazardous materials, such as spent filters or contaminated PPE, helps prevent clutter and reduces the risk of exposure to dangerous substances.

Emergency Procedures

Types of Emergency Situations and Response Actions

Laser Exposure Incidents

Laser exposure is one of the most dangerous hazards in a laser welding environment. Direct exposure to the laser beam, particularly from high-powered sources like CO2 or fiber lasers, can cause severe eye damage (including permanent blindness) and serious skin burns. Laser beams, especially infrared ones, are often invisible and can cause injury even when scattered or reflected off surfaces. The following are countermeasures against laser irradiation:

- Eye Exposure: If a worker’s eyes are exposed to the laser beam, the most critical action is to move the individual away from the laser source immediately. If the exposure is to the eyes, the affected worker should flush their eyes with water for at least 15 minutes and seek medical help without delay. The quicker the intervention, the less the potential for permanent damage.

- Skin Exposure: If the skin is exposed to the laser beam, the immediate response is to cool the affected area using cold water or cool compresses to reduce the severity of burns. For serious burns, emergency medical treatment should be sought immediately. Skin exposure to laser beams can result in first to third-degree burns, depending on the power of the laser and the duration of exposure.

- Preventive Measures: To prevent such incidents, all personnel should wear appropriate laser safety glasses to block harmful wavelengths, and protective barriers or enclosures should be used to contain the laser beam. Ensuring proper machine maintenance and calibration will also reduce the risk of unintentional exposure.

Fire Emergencies

Laser welding generates high heat that can cause nearby materials to catch fire, especially if they are flammable. The intense energy of the laser can also result in sparks or molten material flying out from the welding zone, increasing the potential for ignition. In addition, electrical malfunctions can lead to equipment fires. The following is a fire emergency response:

- Activate Fire Suppression Systems: Many laser welding facilities are equipped with automated fire suppression systems such as sprinklers or CO2-based extinguishers. These systems should be activated immediately in the event of a fire.

- Use of Fire Extinguishers: If the fire is small and manageable, operators should use the correct type of fire extinguisher based on the type of fire. For electrical fires, CO2 extinguishers are recommended, while ABC dry chemical extinguishers are suitable for material fires. All operators must be trained in the proper use of fire extinguishers.

- Evacuate the Area: If the fire cannot be controlled quickly or if it threatens the safety of workers, the area should be evacuated immediately. Emergency exits should be clearly marked, and all personnel should know the fastest evacuation routes. Emergency drills should be conducted regularly to ensure everyone is familiar with evacuation procedures.

- Preventive Measures: To reduce the likelihood of fire, ensure that no combustible materials are within the laser welding area and that flammable materials are properly stored. Regular maintenance of the machine, especially the cooling system, and keeping the surrounding area clear of debris or chemicals, will also help prevent fire hazards.

Electrical Failures and Shock

Laser welding machines use high-voltage components and electrical systems that can fail, leading to equipment malfunctions, sparks, or electrical shock hazards. Electrical failures can result from power surges, equipment damage, or improper maintenance. The following are measures to handle electrical faults:

- Shut Down the Power: The first action in the event of an electrical failure is to immediately shut off the power supply to the machine using the emergency stop button or main disconnect switch. If the power source is not accessible, operators should avoid touching any electrical components.

- Electrical Shock: If an operator experiences an electrical shock, it’s crucial to cut the power supply immediately, then assess the person’s condition. If the person is unresponsive, start CPR and contact emergency medical services. Workers must be trained in basic first aid and CPR for such situations.

- Regular Equipment Inspections: To prevent electrical malfunctions, it is essential to perform regular inspections of the machine’s wiring, power sources, and control systems to ensure everything is functioning properly. Any faulty wiring or equipment should be repaired or replaced immediately.

Fume and Gas Exposure

Laser welding processes can generate harmful fumes and gases, particularly when welding metals with coatings or alloys that produce toxic byproducts. These fumes can lead to respiratory issues, eye irritation, or long-term health effects if inhaled over extended periods. The following are measures to deal with smoke and gas exposure:

- Activate Fume Extraction Systems: If there is an unexpected increase in fumes, operators should immediately turn on or adjust the fume extraction system to enhance airflow and reduce the concentration of harmful substances in the air.

- Evacuate the Area: If the fume levels are dangerous and ventilation does not resolve the issue, workers should evacuate the area immediately and move to a well-ventilated location.

- Use Respirators and PPE: In situations where fume extraction is insufficient, operators should wear appropriate respiratory protection, such as NIOSH-approved respirators, to protect themselves from inhaling harmful particles and gases.

- Seek Medical Help: If an operator begins to experience symptoms of fume exposure, such as coughing, dizziness, or difficulty breathing, medical help should be sought immediately. Workers should be educated on the symptoms of fume inhalation and provided with proper training on how to respond.