Laser Welding Brass Guide

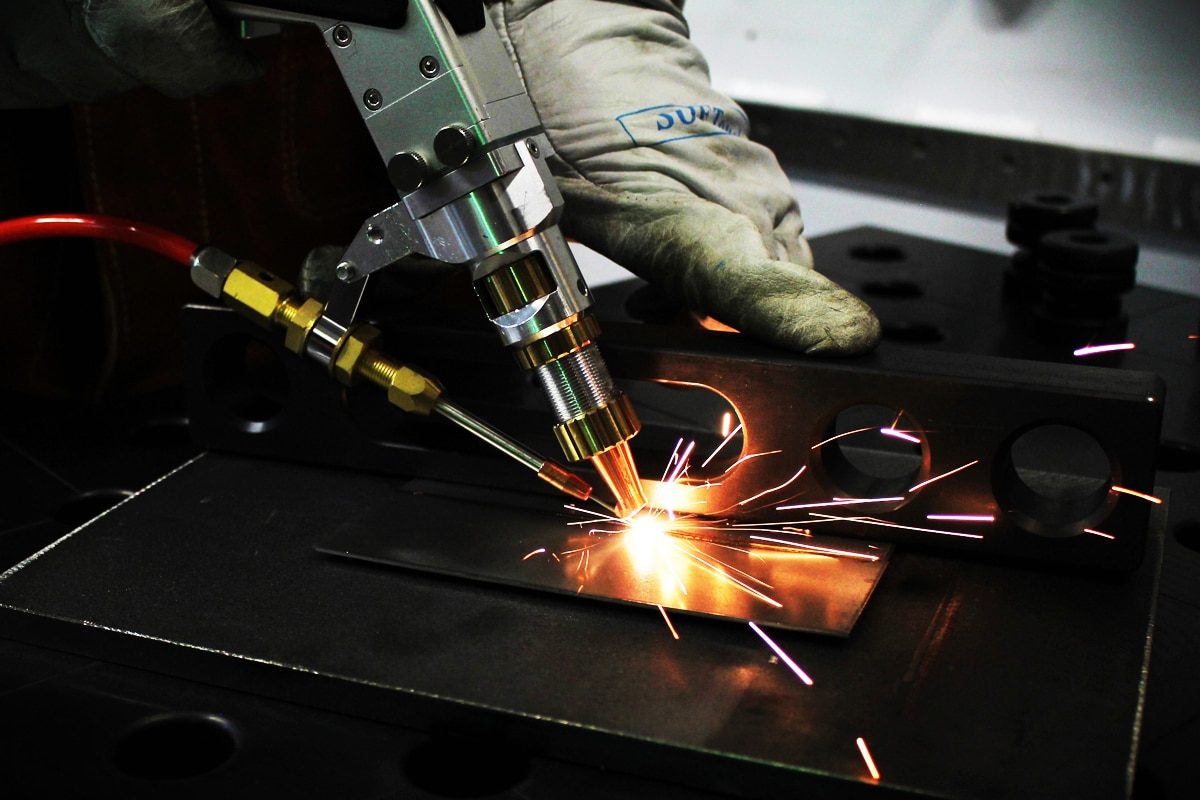

Laser welding has become one of the most advanced and efficient methods for joining metals, prized for its precision, speed, and ability to produce clean, narrow welds with minimal heat distortion. In industries where accuracy and repeatability matter — electronics, automotive manufacturing, aerospace, and precision engineering — laser welding provides capabilities that conventional arc or resistance welding simply cannot match.

Among the many metals used in industry, brass presents both opportunities and challenges. Brass, a copper-zinc alloy, offers outstanding electrical and thermal conductivity, corrosion resistance, and aesthetic appeal. These properties make it invaluable in electrical connectors, plumbing fittings, heat exchangers, and decorative applications. Yet these same traits also make it notoriously difficult to weld. Its high reflectivity to infrared light and the volatility of zinc complicate heat management and energy absorption.

Laser welding, however, provides a modern solution to many of these difficulties. Through careful control of wavelength, pulse energy, shielding gas, and beam focus, it is possible to produce strong, precise, and visually appealing welds in brass. This guide presents a comprehensive examination of how to successfully laser weld brass — exploring its material behavior, process parameters, defect prevention, and best practices.

Table of Contents

Understanding Brass as a Material

Before tackling the specifics of laser welding, it’s crucial to understand what brass is and how it behaves under heat and light. Brass is not a single substance but a family of copper-zinc alloys with widely varying compositions and physical characteristics. These variations directly influence weldability, making metallurgical understanding the foundation for process optimization.

Composition and Alloying Elements

Brass consists primarily of copper (Cu) and zinc (Zn), but the ratio between these two elements greatly affects the alloy’s structure and mechanical properties. Zinc content usually ranges between 5% and 40%.

- Alpha brasses (less than ~35% Zn) are single-phase alloys with a face-centered cubic (FCC) structure. They are highly ductile, easy to form, and relatively easy to weld.

- Alpha-beta brasses (35–45% Zn) contain both the alpha and beta phases. The beta phase adds strength but makes the material less ductile and more sensitive to thermal stress during welding.

Additional elements are sometimes introduced:

- Lead (Pb) improves machinability but creates low-melting inclusions that can promote cracking under thermal stress.

- Tin (Sn) enhances corrosion resistance.

- Aluminum (Al) and silicon (Si) improve strength and surface quality.

Each element alters the alloy’s response to laser energy and heat. Understanding the composition ensures appropriate parameter selection and helps prevent common defects like cracking or porosity.

Brass’s weldability depends strongly on its zinc content and secondary alloying elements. Lower-zinc brasses are easier to weld, while high-zinc or leaded brasses require careful thermal control. Knowledge of alloy composition is the first step toward consistent laser welding success.

Physical and Thermal Properties

Brass’s physical and thermal properties define its response to concentrated laser energy. High conductivity and a wide melting range make it a good heat conductor — and a difficult material to melt uniformly.

The thermal conductivity of brass ranges from 100 to 150 W/m·K, roughly three times that of steel. This high conductivity rapidly dissipates heat away from the weld zone, often requiring higher laser power or reduced welding speed to achieve full penetration.

The melting point of brass depends on zinc content, generally between 900℃ and 940℃. Because zinc boils at 907℃, it begins to vaporize as the alloy nears its melting range. This boiling effect can eject molten droplets, form pores, and alter composition near the weld.

The thermal expansion coefficient of brass (approximately 20 × 10⁻⁶ /K) causes significant expansion and contraction under heat, which can lead to residual stress and warping if not managed through fixturing or balanced heat input.

Brass’s high conductivity and narrow melting range make it sensitive to laser energy fluctuations. Controlling heat input is vital to prevent porosity, distortion, and zinc loss during welding.

Optical Reflectivity

Laser welding depends on energy absorption, but brass’s optical reflectivity makes this difficult. Understanding how brass interacts with laser light determines which laser sources and parameters are most effective.

At infrared wavelengths (about 1 µm), brass reflects up to 90% of incident laser energy. This means that a typical fiber laser operating at 1064 nm struggles to couple energy effectively into the material. The high reflectivity not only wastes energy but can also damage optics through back-reflection.

However, absorption improves dramatically when the surface melts. Molten brass absorbs far more energy than solid brass, enabling a self-sustaining process once melting begins. Techniques such as preheating, surface texturing, or using shorter wavelengths (green or blue lasers) can improve initial absorption and stabilize weld initiation.

Brass reflects most infrared light, complicating energy transfer during laser welding. Overcoming this barrier requires wavelength optimization, surface modification, or controlled preheating to enhance energy absorption.

Brass’s composition, conductivity, and reflectivity collectively define its weldability. Lower-zinc alloys are easier to handle, while high-zinc or leaded brasses pose challenges due to volatility and brittleness. The metal’s thermal and optical characteristics require precise energy control and often specialized lasers to ensure stable and clean welds. Understanding these fundamental properties sets the stage for mastering brass laser welding.

Principles of Laser Welding

Laser welding operates on a simple principle: a focused beam of coherent light delivers high-intensity energy to a small area, heating and fusing the material. But behind this simplicity lies complex thermodynamics, optics, and metallurgy.

Interaction of Laser and Metal

When a laser beam strikes a metal surface, several phenomena occur simultaneously. Part of the energy is reflected, part absorbed, and part transmitted into deeper layers. For brass, reflection dominates initially due to its high optical reflectivity, but as the surface temperature rises, the absorption coefficient increases.

Once sufficient energy density is achieved, localized melting occurs, and the process can transition from conduction-mode welding (surface heating and melting) to keyhole-mode welding, where vaporized material forms a narrow cavity in the melt pool. The keyhole allows the beam to penetrate deeply, achieving strong, narrow welds with minimal distortion.

The efficiency of this interaction depends on:

- Wavelength (shorter wavelengths absorb better).

- Power density (higher intensities overcome reflection).

- Beam focus and stability (ensuring consistent coupling).

In brass, achieving a stable keyhole is difficult due to zinc vaporization and fluctuating reflectivity. Thus, laser type and process settings must be chosen with great care.

Laser-metal interaction governs energy absorption and weld stability. In brass, overcoming reflection and managing keyhole behavior are critical for producing consistent, defect-free joints.

Laser Types Used for Welding

Lasers differ by their gain medium and wavelength, which determine their energy efficiency, absorption characteristics, and suitability for brass.

- CO2 Lasers (10.6 µm): High power but poorly absorbed by brass; seldom used for brass welding.

- Nd:YAG Lasers (1.064 µm): Shorter wavelength improves absorption, but reflection remains an issue.

- Fiber Lasers (~1.07 µm): Highly efficient and widely used in industry; absorption challenges persist but can be mitigated through process control.

- Green Lasers (515–532 nm): Dramatically higher absorption in brass (up to six times better than infrared). Excellent for micro-welding and precision parts.

- Blue Lasers (~450 nm): Exceptional absorption efficiency and growing in industrial use for copper and brass.

- Ultrashort Pulsed Lasers (picosecond or femtosecond): Ideal for microjoining thin foils without significant thermal damage.

While infrared lasers dominate industrial welding, green and blue lasers offer the best absorption for brass. The choice of wavelength directly impacts process stability, weld quality, and energy efficiency.

Laser welding success depends on understanding how light interacts with brass. Achieving proper absorption and stable keyhole formation requires matching laser wavelength, beam parameters, and power density to the alloy’s optical behavior. Shorter-wavelength lasers, such as green or blue, are the most effective at reducing reflection and delivering reliable welds.

Challenges of Laser Welding Brass

Laser welding brass is notoriously complex. While the process promises clean, precise welds, brass’s unique physical and chemical behavior introduces challenges rarely seen in other metals. Chief among these are high reflectivity, zinc vaporization, extreme thermal conductivity, and a tendency toward porosity and cracking. Understanding these challenges — and the science behind them — is crucial for designing effective welding strategies.

Reflectivity

Brass reflects more than 80–90% of incident infrared laser light. This means most of the energy is not absorbed but instead bounced away, often directly back into the optics. This reflection not only reduces welding efficiency but also poses risks to the laser source, potentially damaging lenses or mirrors.

Once the surface begins to melt, absorption improves, but reaching that melting point consistently is difficult. Even small variations in surface finish, oxidation, or angle can drastically change reflectivity. To counter this, many manufacturers use green or blue lasers, which are absorbed far more efficiently, or they modify the surface (roughening, darkening, or coating) before welding.

High reflectivity limits energy coupling in brass welding. Using shorter wavelengths and surface preparation techniques is essential to overcome this barrier and achieve stable melting.

Zinc Evaporation

Zinc, a key element in brass, has a boiling point of 907°C, far lower than copper’s melting point (1085°C). During laser welding, localized temperatures can exceed this threshold instantly, causing zinc to vaporize violently. The escaping vapor can form pores, eject molten droplets (spatter), and alter alloy composition at the weld.

Excessive zinc loss leads to weaker welds with inconsistent color and reduced corrosion resistance. The vapor can also disturb the keyhole, creating instability and potential voids.

Minimizing zinc evaporation requires precise control of laser power, optimized shielding gas flow, and sometimes preheating to reduce thermal gradients.

Zinc’s low boiling point makes vaporization unavoidable, but controlled heat input, proper shielding, and process optimization can minimize porosity and compositional imbalance.

Thermal Conductivity

Brass’s high thermal conductivity rapidly spreads heat away from the laser spot, reducing the local temperature and making it hard to maintain a molten pool. This leads to incomplete penetration or shallow welds unless compensated with higher power or slower travel speed.

At the same time, this conductivity increases the risk of distortion, especially in thin sections. The key is to find a balance — enough heat for fusion, but not so much that the entire part overheats.

Thermal conductivity in brass demands careful control of heat flow. Balancing laser power and travel speed ensures sufficient penetration while preventing overheating and distortion.

Porosity and Cracking

Porosity arises when zinc vapor bubbles become trapped during solidification. Cracking often follows due to thermal stress and rapid cooling. High-zinc and leaded brasses are especially vulnerable because they solidify over a wide temperature range, allowing gases to remain trapped.

To minimize these defects, the process must maintain a stable molten pool and controlled cooling rate. Using pulsed laser modes and shielding gases like helium helps reduce porosity and spatter.

Porosity and cracking stem from zinc vaporization and uneven solidification. Controlled heat input, stable keyhole formation, and optimized shielding gas flow are key to preventing these issues.

Brass’s weldability challenges stem from its physical nature — reflective, conductive, and volatile. The key to success is understanding each problem’s root cause and applying strategies like wavelength optimization, heat control, and gas management. These adjustments transform brass from a difficult-to-weld alloy into a material suitable for precise, repeatable laser joining.

Optimizing the Process

Overcoming the inherent challenges of brass welding requires strategic process optimization. Successful welding depends on balancing energy input, heat distribution, and vapor management. Every variable — from wavelength and power density to gas type and travel speed — interacts to determine weld quality.

Improving Absorption

Improving absorption is the foundation of reliable brass welding. Several methods are used:

- Laser wavelength selection: Green (515 nm) and blue (450 nm) lasers offer superior absorption efficiency.

- Surface roughening or coating: Applying a thin absorptive film (graphite, oxide, or carbon-based) increases initial coupling.

- Preheating: Heating the brass to 200–300℃ lowers reflectivity and reduces thermal gradients.

Combining these techniques can stabilize the welding process, especially in reflective or polished components. Enhancing energy absorption through wavelength control, surface treatment, or preheating greatly improves weld initiation and consistency.

Laser Parameters

Key laser parameters include power, spot size, focus position, and welding speed. High power ensures penetration but risks zinc loss; too low, and the weld becomes shallow or discontinuous.

For precision work, pulsed lasers allow better control over heat input, while continuous-wave (CW) lasers suit larger joints. The focus position should typically be slightly below the surface to maximize energy delivery into the joint.

Fine-tuning laser parameters achieves the balance between adequate penetration and minimal zinc vaporization — the central challenge of brass welding.

Shielding Gas

Shielding gas protects the molten pool from oxidation and stabilizes the keyhole. Argon is common, but helium provides deeper penetration and smoother welds due to its higher ionization potential. Gas flow should be laminar; excessive turbulence can introduce porosity.

Proper gas selection and delivery are vital for clean welds. Helium often yields superior results but at a higher cost. Controlled gas flow prevents oxidation and porosity.

Welding Speed

Travel speed affects both heat input and zinc vaporization. Slow speeds increase penetration but risk spatter; fast speeds reduce heat input and may cause lack of fusion. The optimal speed range depends on material thickness and laser type.

Welding speed directly influences bead shape and defect formation. The correct balance ensures full fusion without excessive zinc evaporation.

Pulse vs Continuous Wave Operation

Pulsed lasers deliver high peak power in short bursts, allowing controlled heat buildup and reduced zinc evaporation — ideal for small components. Continuous-wave (CW) operation provides consistent melting for larger joints but demands stricter cooling control.

Pulsed lasers offer precision and reduced thermal stress; continuous-wave systems excel in productivity. The choice depends on part geometry and performance requirements.

Optimizing brass laser welding involves managing reflectivity, vaporization, and thermal flow. Adjusting wavelength, power, gas type, and speed allows the welder to fine-tune results for different alloys and geometries. Process control transforms brass welding from unstable to predictable, ensuring repeatable results.

Suitable Laser Types

Not all lasers are equally suited for brass welding. The choice of laser source — fiber, green, blue, or ultrafast — dictates absorption efficiency, weld quality, and process cost. This section compares the performance of different laser types and their suitability for various brass applications.

Fiber Lasers

Fiber lasers are widely used in industry for their high efficiency, compact design, and reliability. Operating at approximately 1070 nm, they produce fine, stable beams capable of deep penetration. However, brass’s high reflectivity at this wavelength means that achieving consistent melting can be challenging without coatings or higher power levels.

Fiber lasers are versatile and efficient, but require reflection management for brass. They remain popular due to industrial maturity and automation compatibility.

Green Lasers

Green lasers, emitting around 515 nm, provide far superior absorption in brass — roughly six times higher than infrared lasers. They enable precise, low-defect welding at lower power levels, making them ideal for microelectronics and fine assemblies.

Green lasers are currently the most effective choice for high-quality brass welding, balancing energy efficiency with superior weld consistency.

Blue Lasers

Blue lasers (around 450 nm) represent the next generation of metal welding technology. Brass absorbs blue light exceptionally well, allowing immediate melting without the need for coatings or preheating. They excel in fine electrical connectors and thin foils.

Blue lasers deliver unmatched absorption and process stability, ideal for high-reflectivity metals like brass.

Ultrafast Lasers

Ultrashort-pulse lasers (picosecond or femtosecond) minimize heat diffusion by confining energy within nanometer-scale regions. This enables micro-welding of thin or delicate parts with almost no thermal damage — perfect for sensors and precision electronics.

Ultrafast lasers enable microjoining without significant heat effects, making them ideal for precision brass applications where accuracy outweighs speed.

Laser type determines the quality, efficiency, and feasibility of brass welding. While fiber lasers remain industrial workhorses, green and blue lasers dominate precision work due to their superior absorption. Ultrafast lasers offer unmatched control for microscale welding, positioning them at the frontier of advanced manufacturing.

Joint Design and Preparation

Even the best laser and process settings cannot compensate for poor joint design or preparation. Clean surfaces, accurate fit-up, and stable fixturing are the foundation of defect-free welding.

Surface Cleaning

Surface contamination — oil, oxide, or dust — drastically reduces laser absorption and can cause porosity or incomplete fusion. Cleaning methods include solvent degreasing, ultrasonic cleaning, or light abrasive treatment. Clean surfaces ensure stable absorption and defect-free welds. Neglecting cleaning leads to spatter and porosity.

Edge Preparation

Edges should be smooth and properly aligned. Sharp edges or burrs can scatter the laser beam and cause uneven melting. For thicker materials, small bevels or chamfers promote full penetration. Proper edge preparation ensures uniform melting and joint strength, particularly in thicker brass components.

Fixturing

Brass expands significantly when heated. Secure fixturing prevents distortion and misalignment during welding. Fixtures must hold parts firmly yet allow for thermal expansion to avoid stress buildup. Good fixturing maintains joint alignment and dimensional accuracy while reducing residual stress.

Joint Configurations

Common joint designs include butt, lap, and fillet joints. Butt joints are preferred for full penetration, while lap joints are easier to align but may trap gases. The design should minimize gaps and ensure uniform energy distribution. Choosing the right joint configuration improves mechanical integrity and weld quality. Tight fit-up and minimal gaps are essential for brass.

Joint design and preparation form the backbone of reliable brass welding. Clean, well-fitted joints supported by stable fixtures ensure consistent results. Preparation is not a preliminary step — it’s a defining factor in weld quality, especially for sensitive materials like brass.

Common Defects and Prevention

Even with optimized settings, laser welding brass can suffer from characteristic defects that compromise mechanical strength and appearance. Understanding how these flaws form and how to prevent them is central to mastering the process. The most common issues are porosity, cracking, spatter, and undercut or incomplete fusion.

Porosity

Porosity appears as tiny voids within or near the weld bead. In brass, these are mainly caused by trapped zinc vapor. When the molten pool solidifies too quickly, gas bubbles cannot escape, leaving voids that weaken the joint and reduce conductivity.

Prevention involves:

- Lowering the laser peak power to reduce zinc boiling.

- Maintaining steady keyhole formation.

- Using helium or helium-argon mixtures for faster gas evacuation.

- Applying mild preheating to slow solidification.

Porosity results from trapped vapor bubbles. Stabilizing the melt pool, moderating power, and using suitable shielding gas significantly reduce pore formation.

Cracking

Cracks form from residual stresses that exceed the alloy’s strength during cooling. High-zinc and leaded brasses are particularly vulnerable because they solidify over a wide temperature range and exhibit low ductility in the semi-solid state.

To prevent cracking:

- Use pulsed or ramp-down power modes to reduce thermal shock.

- Minimize restraint in fixtures so parts can expand freely.

- Avoid rapid cooling by preheating or adjusting gas flow.

Cracking stems from thermal stress and low ductility during solidification. Controlled cooling and flexible fixturing help eliminate it.

Spatter

Spatter occurs when molten droplets are ejected from the weld pool due to violent zinc vaporization or excessive laser power density. It not only mars surface finish but can also contaminate optics and neighboring parts.

Mitigation strategies include:

- Using shorter wavelengths (green or blue) reduces the required energy.

- Reducing peak power or applying pulse shaping.

- Ensuring smooth gas shielding and avoiding turbulent flow.

Spatter indicates over-aggressive energy input. Gentle parameter control and wavelength optimization produce smoother, cleaner welds.

Undercut or Incomplete Fusion

These defects occur when laser energy or joint fit-up is insufficient to melt both sides of the interface. Causes include low power, excessive speed, misalignment, or surface contamination.

Prevention involves precise focusing, consistent joint gaps below 0.1 mm, and thorough cleaning before welding.

Undercut and incomplete fusion reflect insufficient energy or poor preparation. Careful alignment, correct focus, and clean surfaces ensure full penetration and uniform welds.

Most brass-welding defects trace back to zinc vaporization and inconsistent energy delivery. Managing thermal input, shielding, and mechanical restraint minimizes porosity, cracking, and spatter. Preventive discipline, not post-repair, ensures long-term weld integrity.

Testing and Quality Control

Quality assurance verifies that brass welds meet mechanical, electrical, and visual requirements. Because laser welding operates at fine tolerances, even minor deviations can lead to significant functional failures. Testing spans from visual checks to advanced non-destructive evaluation.

Visual Inspection

The first step is always a trained visual assessment. Inspectors look for smooth bead appearance, uniform width, and absence of discoloration or spatter. Any irregularity often signals deeper issues such as porosity or lack of fusion. Visual inspection provides quick feedback on process stability and should be performed for every part batch.

Microscopic Examination

High-magnification optical or scanning-electron microscopy reveals grain structure, micro-cracks, and porosity invisible to the naked eye. Etching cross-sections helps study heat-affected zones and metallurgical transformations. Microscopic analysis exposes internal flaws and validates microstructure quality, crucial for fine-tolerance components.

Non-Destructive Testing

Techniques such as ultrasonic, X-ray, or eddy-current testing detect subsurface defects without damaging the part. For thin brass, X-ray radiography is most effective because of its sensitivity to small voids. Non-destructive testing ensures weld reliability in production without sacrificing samples, ideal for high-value components.

Mechanical Tests

Tensile, shear, and hardness tests measure the weld’s mechanical strength relative to the base material. Properly welded brass joints can achieve up to 90–100% of parent-metal strength when parameters are correct. Mechanical testing quantifies joint integrity and verifies that process settings yield functional strength.

Leak Tests

In applications such as plumbing, refrigeration, and sensors, leak testing under pressure or with tracer gases confirms hermetic sealing. Leak testing validates real-world performance, ensuring welds are both strong and airtight.

Quality control in brass laser welding integrates visual, microstructural, and mechanical assessments. Reliable welding demands systematic verification — combining rapid in-line inspection with periodic in-depth analysis to maintain consistent standards.

Applications

Laser-welded brass components appear in nearly every sector where precision, conductivity, and corrosion resistance matter. The combination of automation-friendly laser systems and brass’s functional properties has created a broad range of industrial uses.

Electronics

Brass’s conductivity and formability make it ideal for connectors, terminals, and sensor housings. Laser welding allows micron-level accuracy and minimal thermal impact on surrounding circuitry. In electronics, laser welding delivers precise, repeatable joints without damaging heat-sensitive parts.

Automotive

Modern vehicles rely on brass for electrical contacts, fuel-system fittings, and temperature sensors. Laser welding ensures compact, leak-tight joints that withstand vibration and corrosion. Automotive brass components benefit from laser welding’s combination of strength, speed, and cleanliness.

Aerospace

In aerospace systems, brass appears in instrumentation, hydraulic connectors, and communication components. Laser welding’s narrow heat-affected zone preserves dimensional stability and prevents contamination. Aerospace applications exploit laser welding for its precision and ability to join delicate assemblies without rework.

Decorative Arts

Brass’s golden luster makes it popular in musical instruments, lighting, and jewelry. Laser welding allows nearly invisible seams, preserving aesthetics while maintaining strength. For decorative pieces, laser welding offers both beauty and durability, blending art with engineering.

HVAC and Plumbing

Heat exchangers and plumbing fittings require airtight, corrosion-resistant joints. Laser welding provides fast, automated sealing with minimal post-processing. In HVAC and plumbing, laser welding enhances production speed and reliability, ensuring leak-free operation.

Laser-welded brass serves industries from microelectronics to heavy manufacturing. The process’s adaptability — precision for small parts and power for robust joints — secures its place as a cornerstone of modern fabrication.

Safety Considerations

Laser welding introduces hazards distinct from conventional welding. Operators must guard against optical, thermal, electrical, and fume risks. Brass adds a particular danger: zinc vapor, which can be toxic if inhaled. Safe operations combine proper equipment, ventilation, and personal protective measures.

Laser Radiation

Exposure to direct or reflected laser beams can cause eye and skin injuries. Enclosed workcells, interlocks, and wavelength-specific protective eyewear are mandatory. Beam paths should be shielded, and reflective surfaces minimized. Laser safety relies on containment, interlocks, and correct eyewear matched to the laser wavelength.

Fumes

Zinc vaporizes readily, forming zinc oxide fumes that irritate the respiratory system. Local exhaust ventilation and HEPA filtration remove fumes at the source. Operators should never rely solely on room ventilation. Effective fume extraction is essential when welding brass, preventing zinc-oxide exposure, and ensuring a safe workspace.

Electrical and Fire Safety

High-power lasers require robust grounding and surge protection. Because brass reflects heat, stray reflections can ignite flammable materials nearby. Maintain clean, uncluttered work areas and follow lock-out procedures during maintenance. Proper grounding, housekeeping, and lock-out practices prevent electrical hazards and fires in laser welding environments.

Laser welding safety integrates optical protection, fume control, and disciplined electrical management. Brass adds the extra demand of vapor containment. With rigorous adherence to standards like ANSI Z136 and ISO 11553, the process remains safe and sustainable.

Summary

Laser welding of brass blends art, physics, and precision engineering. Brass’s high reflectivity, thermal conductivity, and zinc volatility once made it a challenging material.

Laser welding has elevated brass fabrication from an art of compromise to a science of precision. With the right equipment, parameters, and understanding, engineers can achieve strong, repeatable, and aesthetically superior welds — proving that even the most reflective and volatile alloys can yield to the focused brilliance of a laser beam.

Get Laser Welding Solutions

At Maxcool CNC, we understand that welding brass is not just about melting metal — it’s about achieving precision, reliability, and efficiency in every joint. As a professional manufacturer of intelligent laser equipment, we provide end-to-end solutions designed specifically for the challenges of brass welding, including high reflectivity, zinc vaporization, and thermal control.

Our laser welding systems deliver exceptional absorption rates and stable energy output, ensuring consistent results across diverse brass alloys and component geometries. Whether you’re producing fine electrical connectors, decorative fittings, or industrial assemblies, Maxcool CNC’s technology integrates advanced beam control, real-time monitoring, and automated process optimization to deliver flawless welds with minimal rework.

Beyond equipment, we offer comprehensive application support, from process development and sample testing to customized automation and operator training. Our engineering team helps you fine-tune parameters to achieve optimal speed, penetration, and surface quality.

Choosing Maxcool CNC means more than buying laser welding systems — it means gaining a trusted partner in precision manufacturing. Contact Maxcool CNC today to discover intelligent laser welding solutions tailored to your production needs and set a new benchmark in brass welding performance.