Introduction

Available Models

Application

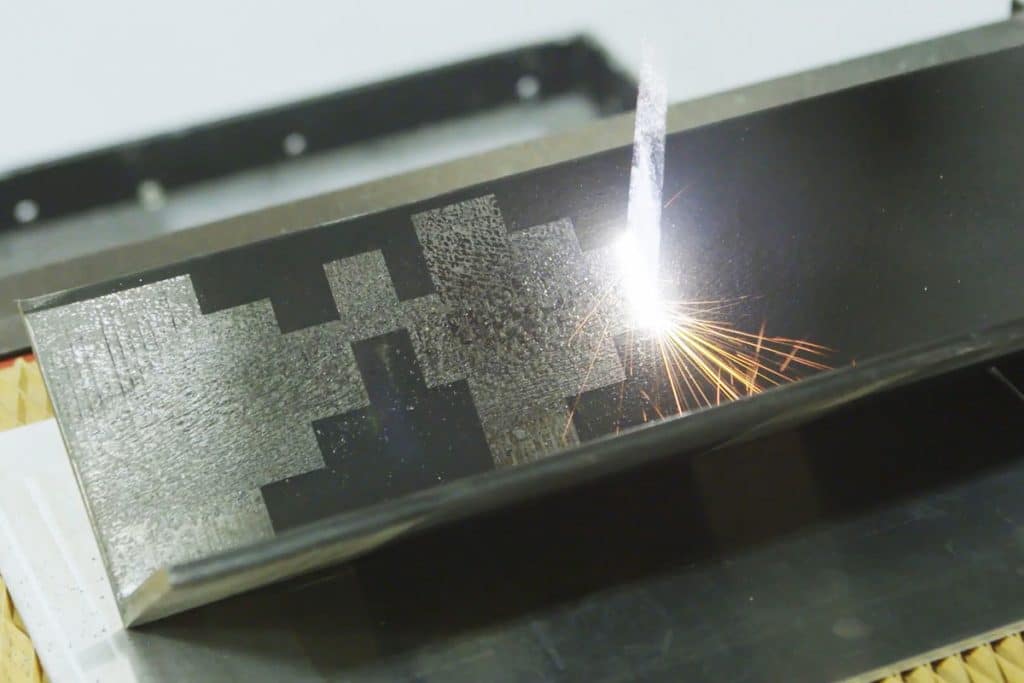

Laser graffiti removal machines are versatile tools that cater to a wide range of cleaning and restoration needs. Their precision and eco-friendly operation make them suitable for various applications, including:

- Public Space Maintenance: Efficiently remove graffiti and markings from walls, sidewalks, bridges, and other public surfaces to restore cleanliness and aesthetics.

- Commercial Building Restoration: Clean graffiti from building exteriors, windows, and signage without damaging the underlying materials, such as stone, brick, or glass.

- Historical Preservation: Gently remove graffiti and unwanted markings from historic monuments, statues, and cultural landmarks without harming delicate or porous surfaces.

- Transportation Maintenance: Remove graffiti from vehicles, trains, buses, and subway stations, ensuring a clean and professional appearance.

- Industrial Cleaning: Eliminate graffiti from industrial equipment and facilities, maintaining operational integrity and visual appeal.

- School and Campus Cleaning: Keep educational institutions graffiti-free, preserving a clean and welcoming environment for students and staff.

Comparison with Traditional Cleaning Methods

| Feature | Laser Graffiti Removal | Sandblasting | Chemical Cleaning | Ultrasonic Cleaning |

| Precision | High precision, removes graffiti without damaging surfaces | Moderate precision may damage delicate surfaces | Limited precision, risk of material corrosion | Best for small, intricate parts, not suitable for walls or large areas |

| Environmental Impact | Eco-friendly, no chemicals or abrasives used | Generates dust and abrasive waste | Uses harsh chemicals, creates toxic waste | Eco-friendly, but requires detergents |

| Cleaning Speed | Fast and efficient, with minimal downtime | Moderate, depending on the surface type and size | Slower, requires soaking and rinsing | Moderate, effective only for small objects |

| Setup Time | Minimal setup, ready to use quickly | Requires setup of abrasive materials and equipment | Involves chemical preparation and safety measures | Requires cleaning tank and solution preparation |

| Safety | Non-contact, safe for operators and surfaces | Risks from flying debris require PPE | Risks from chemical exposure need strict protocols | Generally safe, but cleaning agents can irritate |

| Waste Generation | Minimal, only vaporized particles | Significant dust and abrasive residue | Produces hazardous chemical waste | Minimal, but the used solution needs disposal |

| Surface Compatibility | Safe for delicate and porous materials | Abrasive, not suitable for sensitive surfaces | Can corrode or discolor certain materials | Limited to small, non-porous items |

| Portability | Compact, portable models available for on-site use | Bulky, not easily portable | Fixed setup, not portable | Requires stationary tank setup |

| Operating Cost | Low long-term cost, no consumables required | Moderate, requires a constant supply of abrasives | High, continuous purchase of chemicals | Moderate, depending on solution usage frequency |

| Durability | Durable components, minimal maintenance required | Equipment prone to wear from abrasives | Chemicals degrade over time, and frequent replacement is needed | Equipment requires regular maintenance |

Why Choose Us

Cutting-Edge Technology

Maxcool CNC is committed to integrating the latest technological advancements into our machines. Our laser cleaning machines feature precise control, high efficiency, and superior performance, ensuring optimal cleaning results for various industrial applications.

Reliable and Durable Equipment

Our machines are built to last, with robust construction and high-quality components that guarantee long-term reliability and minimal maintenance. You can trust Maxcool CNC to provide equipment that withstands even the toughest environments.

Comprehensive Support

From pre-sales consultation to after-sales technical assistance, we are with you every step of the way. Our dedicated support team ensures you have all the information and help you need to maximize the value of your investment.

Sustainability and Efficiency

Maxcool CNC’s laser cleaning machines are designed with energy efficiency in mind, reducing power consumption without compromising performance. This not only lowers operational costs but also contributes to a more sustainable future.

Customer Reviews

Frequently Asked Questions

Is Laser Graffiti Removal Safe to Use?

Can Laser Graffiti Removal Damage Surfaces?

What Types of Surfaces Can Laser Graffiti Removal Machines Clean?

How Fast Can Laser Graffiti Removal Machines Clean Surfaces?

What Safety Equipment is Needed to Operate Laser Graffiti Removal Machines?

Do Laser Graffiti Removal Machines Require Special Training?

Related Resources

Laser Cleaning VS Dry Ice Blasting

Comprehensive guide comparing laser cleaning and dry ice blasting: principles, equipment, applications, speed, surface effects, safety, environmental impact, costs, and selection criteria.

Applications of Pulsed Laser Cleaning

This article explores the diverse applications of pulsed laser cleaning across industries, highlighting its principles, benefits, and impact on modern maintenance and manufacturing.

Does Laser Cleaning Affect Surface Roughness and Cleanliness?

This article explores the fundamentals of laser cleaning, its effects on surface roughness and cleanliness, key parameters, advantages, limitations, and applications across major industries.