Understanding Laser Cutting and Fume Generation

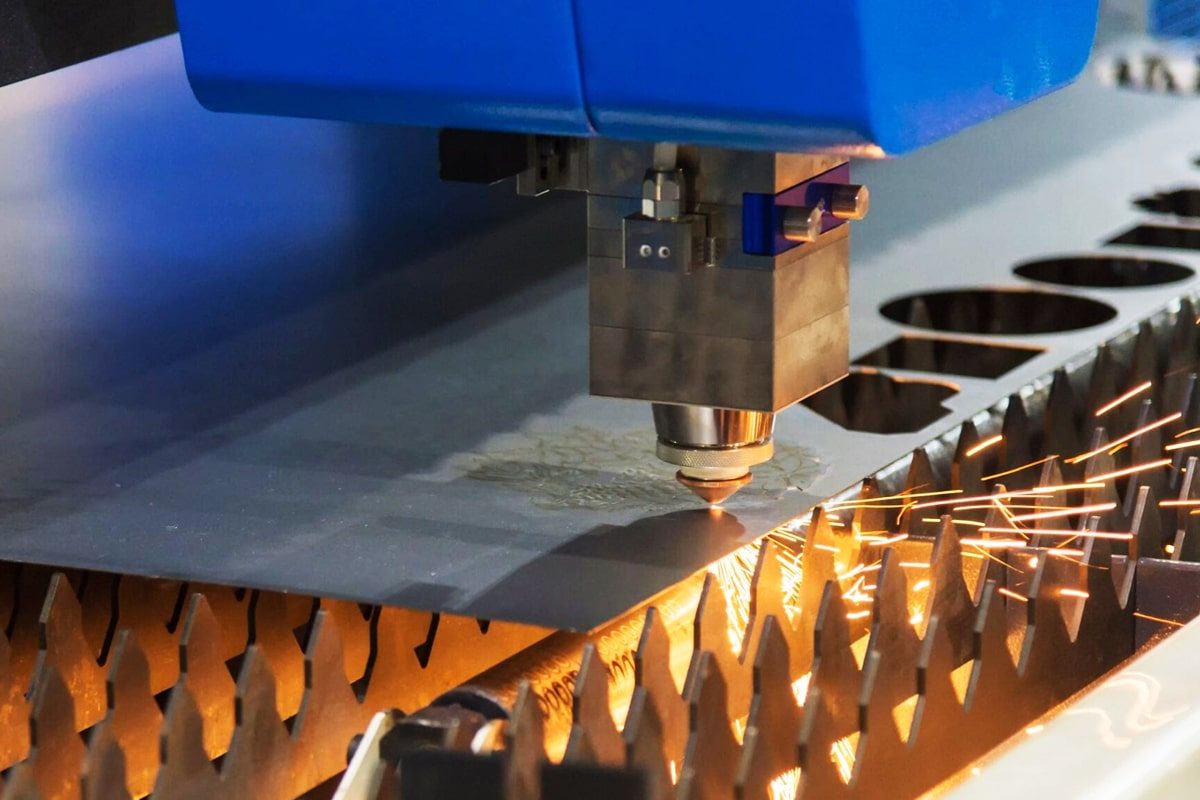

How Laser Cutting Works

Laser cutting directs a high-energy beam of light onto a material’s surface. Concentrated through a lens, this beam generates temperatures of thousands of degrees Celsius at a pinpoint location. The material is removed in different ways depending on the process:

- Fusion Cutting (melting): The laser melts the material, and an assist gas like nitrogen or air blows it out of the cut.

- Reactive Cutting (burning): Oxygen is used to ignite the hot metal, producing an exothermic reaction that speeds up cutting but also increases oxide formation.

- Vaporization (sublimation): For some materials, like wood or certain plastics, the laser instantly vaporizes the surface into smoke and vapor.

What Are Laser Cutting Fumes?

The term laser cutting fumes refers to the airborne byproducts generated when material is thermally altered by the laser. These can be divided into three broad categories:

- Ultrafine Particulate Matter (dust and smoke): Particles often smaller than 1 micron, easily inhaled deep into the lungs. Metals produce metal oxides, while organics form carbonaceous soot.

- Gaseous Compounds: Carbon monoxide, carbon dioxide, water vapor, and volatile organic compounds (VOCs). Some processes may also generate ozone or nitrogen oxides.

- Material-specific emissions:

- Metals: Cutting stainless steel or alloys can release hazardous oxides like hexavalent chromium and nickel. Aluminum and titanium form fine oxide powders.

- Plastics and Polymers: Acrylics release methyl methacrylate (MMA); polycarbonate can produce phenols; PVC can emit hydrogen chloride and dioxins—particularly hazardous.

- Wood and Composites: Burning releases smoke, tars, formaldehyde, acrolein, and resin decomposition products in engineered woods and laminates.

The Composition of Laser Cutting Fumes

Metals

When metals are cut, the extreme heat oxidizes the surface, creating ultrafine metal oxide particles. These particles are often invisible but can remain airborne for long periods.

- Mild Steel: Generates iron oxides, generally considered less toxic but still harmful in high concentrations.

- Stainless Steel: Produces chromium and nickel oxides. Under high-heat oxidative conditions, hexavalent chromium (Cr VI) may form, a known carcinogen and respiratory hazard.

- Aluminum, Titanium, Copper: Release their respective oxides as very fine powders. Some (like aluminum oxide) are classified as respiratory irritants, while others (like copper oxide) can cause metal fume fever.

Plastics and Polymers

Plastics behave very differently because they decompose chemically when heated. Instead of oxides, they release volatile organic compounds (VOCs) and other gases.

- Acrylic (PMMA): Emits methyl methacrylate (MMA), which has a sharp odor and can irritate eyes, skin, and lungs.

- Polycarbonate: Releases phenolic compounds and bisphenol-A derivatives, which are harmful in repeated exposure.

- PVC: One of the most dangerous plastics to laser cut. It produces hydrogen chloride gas, which is corrosive, as well as chlorinated dioxins, which are highly toxic and persistent in the environment.

- Other Polymers (nylon, ABS, etc.): Can generate cyanide compounds, styrene, and other VOCs linked to neurological and respiratory effects.

Wood and Organic Materials

Wood, paper, and other organic materials mainly undergo pyrolysis, creating smoke made up of fine soot particles and organic gases.

- Natural Woods: Release carbon monoxide, carbon dioxide, tar, and irritants like acrolein and formaldehyde.

- Engineered Woods (MDF, plywood, particleboard): Much more hazardous due to the resins and adhesives they contain. Cutting these can release high levels of formaldehyde, isocyanates, and other resin byproducts.

Composites and Coated Materials

Cutting composites or coated surfaces introduces additional hazards because multiple materials are involved.

- Carbon Fiber Composites: Can release fine carbon dust as well as epoxy resin byproducts like phenols and amines.

- Fiberglass (glass fiber + resin): Produces sharp glass micro-fragments and toxic resin decomposition products.

- Painted or Coated Metals: Burning paint or powder coating can release lead, cadmium, isocyanates, or VOCs, depending on the coating composition.

Health Hazards of Laser Cutting Fumes

Short-Term Exposure Effects

Even brief exposure to laser cutting fumes can trigger immediate health problems, especially in poorly ventilated workshops. Common short-term effects include:

- Respiratory Irritation: Coughing, throat irritation, shortness of breath, or chest tightness caused by inhaling fine particulates and VOCs.

- Eye and Skin Irritation: Smoke and gases like acrolein, formaldehyde, or hydrogen chloride can irritate mucous membranes and cause watery eyes or skin rashes.

- Headaches, Dizziness, and Nausea: VOCs such as styrene, phenols, or MMA (from acrylics) can affect the central nervous system, producing acute discomfort.

- Metal Fume Fever: Cutting metals such as zinc, copper, or aluminum can cause flu-like symptoms (fever, chills, fatigue) within hours of exposure.

Long-Term Exposure Risks

Chronic exposure to laser cutting fumes poses much more serious risks. Prolonged inhalation of ultrafine particles and toxic compounds has been linked to:

- Chronic Respiratory Disease: Asthma, bronchitis, and reduced lung capacity from repeated irritation and inflammation.

- Carcinogenic Effects: Long-term exposure to hexavalent chromium (from stainless steel), nickel compounds, or formaldehyde is strongly associated with increased cancer risk.

- Neurological Damage: Persistent exposure to styrene, phenolic compounds, or other solvents may contribute to memory problems, cognitive decline, or nerve damage.

- Systemic Toxicity: Certain heavy metals (lead, cadmium) and chemical vapors (isocyanates, dioxins) can accumulate in the body, affecting the liver, kidneys, and immune system.

Occupational Standards

Regulatory agencies worldwide have established limits to protect workers from hazardous emissions:

- OSHA (U.S.): Sets Permissible Exposure Limits (PELs) for substances like hexavalent chromium (5 µg/m³), nickel (1 mg/m³), and formaldehyde (0.75 ppm as an 8-hour TWA).

- NIOSH (U.S.): Issues Recommended Exposure Limits (RELs), often stricter than OSHA’s, and recognizes welding and cutting fumes as potential occupational carcinogens.

- EU Directives: European standards (such as Directive 2004/37/EC) regulate carcinogenic, mutagenic, and toxic agents, with binding occupational exposure limits for chromium, nickel, and formaldehyde.

- General Dust and Particulates: Both OSHA and EU guidelines emphasize keeping exposure to respirable dust and ultrafine particles as low as reasonably achievable.

Environmental Impact of Laser Cutting Fumes

Air Pollution

When fumes are not captured effectively, they disperse into the atmosphere as particulate matter (PM) and volatile organic compounds (VOCs).

- Particulate Matter: Ultrafine particles (<1 µm) from metal oxides or carbon soot can remain airborne for long periods, contributing to smog formation and posing risks to surrounding communities.

- VOCs: Compounds from plastics, wood resins, and coatings can react with nitrogen oxides in the air to form ground-level ozone, a major pollutant regulated under clean air laws.

Greenhouse Gases

Laser cutting itself consumes significant electricity, but the fumes can also play a role in greenhouse gas emissions:

- Carbon Dioxide (CO2): Generated when organic materials (wood, plastics) combust under the laser.

- Carbon Monoxide (CO): Produced from incomplete combustion, a short-lived climate pollutant as well as a toxic gas.

- Methane and Other Organics: Certain polymers may degrade into hydrocarbons that have high global warming potential.

Hazardous Waste

Fume extraction systems capture pollutants in filters, cartridges, and activated carbon beds. Over time, these filters accumulate hazardous residues:

- Metal-Laden Dust: Contains oxides of chromium, nickel, or lead, often classified as hazardous waste under environmental law.

- Chemical-Saturated Filters: Activated carbon filters can become loaded with VOCs, solvents, and acidic gases, requiring careful disposal.

- Resin and Composite Byproducts: Cutting fiberglass, epoxy, or coated materials produces residues that are not biodegradable and may leach toxic compounds in landfills.

Indoor Air Quality

Perhaps the most immediate environmental concern is indoor air quality (IAQ). In workshops without effective extraction, fumes accumulate and degrade the breathing environment.

- High particle concentrations reduce visibility and create an unsafe workspace.

- VOC buildup can cause persistent odors and discomfort for employees.

- Long-term poor IAQ contributes to “sick building syndrome,” reducing productivity and increasing absenteeism.

Risk Factors That Influence Toxicity

Material Type

The composition of the material is the single most important factor:

- Metals: Cutting stainless steel, galvanized steel, or alloys can release hazardous oxides such as hexavalent chromium, nickel, or zinc.

- Plastics and Polymers: PVC, acrylic, polycarbonate, and composites release VOCs, acidic gases, or dioxins—some of which are known to be carcinogenic.

- Woods and Organics: Natural wood produces smoke and aldehydes; engineered wood releases more toxic resins and adhesives, such as formaldehyde and isocyanates.

- Coated or Painted Materials: Add an extra layer of danger, as paints, adhesives, or powder coatings can emit additional VOCs or heavy metals.

Laser Power and Speed

The cutting parameters directly affect fume volume and composition:

- High Power / Slow Speed: Increases thermal load, causing more material to burn or vaporize. This results in denser fumes and a greater risk of harmful byproducts.

- Low Power / Fast Speed: Produces less fume overall, but incomplete vaporization may generate more particulates and soot.

- Pulse vs Continuous Beams: Pulsed lasers may create bursts of fine particulates, while continuous lasers produce a steadier emission stream.

Assist Gas Used

Assist gases influence both cutting chemistry and fume profile:

- Oxygen: Promotes exothermic reactions, increasing oxidation and generating more metal oxides. Cutting stainless steel with oxygen raises the chance of producing hexavalent chromium.

- Nitrogen: Provides an inert atmosphere, reducing oxidation and producing cleaner edges with fewer oxide particles.

- Air: A cost-effective option, but contains oxygen and nitrogen, leading to a mix of oxide particulates and possible nitrogen oxides.

Duration of Exposure

Exposure risk is cumulative.

- Short-Term Exposure: May cause acute irritation, headaches, or temporary respiratory symptoms.

- Long-Term, Repeated Exposure: Increases the risk of chronic diseases such as asthma, COPD, or even cancer.

- Cumulative Dose Matters: Even if fume concentrations are low, extended daily exposure without proper controls builds up risk over time.

Workplace Ventilation

The work environment determines whether fumes disperse harmlessly or concentrate to dangerous levels.

- Poor Ventilation: Allows particulates and gases to accumulate indoors, leading to unsafe air quality.

- Local Exhaust Ventilation (LEV): Captures fumes directly at the source, reducing worker exposure significantly.

- General HVAC Systems: Useful for dilution, but insufficient on their own without targeted fume extraction.

- Filter Maintenance: Even well-designed systems fail if filters are clogged or not replaced regularly, allowing hazardous buildup.

Mitigation Strategies

Local Exhaust Ventilation (LEV)

LEV systems are the first line of defense against fumes. They capture emissions as close as possible to the point of generation, preventing them from dispersing into the work environment.

- Downdraft Tables and Extraction Arms: Pull fumes directly away from the operator.

- Integrated Laser Cutting Machine Extraction Ports: Designed into the machine for efficient capture.

- Best Practice: Capture should occur within a few centimeters of the cut zone; otherwise, fine particles may escape.

Filtration Systems

Captured fumes must be treated before being released back into the workshop or outside air. This is where filtration systems come in:

- HEPA Filters: Trap ultrafine particulate matter down to 0.3 microns, including metal oxides.

- Activated Carbon Filters: Absorb gases, VOCs, and odors from plastics and coatings.

- Multi-Stage Filtration: Combining pre-filters, HEPA, and carbon ensures comprehensive protection.

- Maintenance: Filters must be replaced on schedule, as saturated filters become ineffective and can even release contaminants back into the air.

Enclosures and Isolation

Another effective method is physically separating cutting operations from the rest of the workspace:

- Fully Enclosed Laser Systems: Keep fumes contained within the machine until extraction and filtration are complete.

- Dedicated Cutting Rooms or Booths: Isolate the process, limiting exposure to non-operators.

- Automation: Using robotic loading/unloading reduces the need for operators to be close to the fume source.

Personal Protective Equipment (PPE)

While engineering controls should always be the priority, PPE provides an additional layer of defense:

- Respiratory Protection: N95, P100, or powered air-purifying respirators (PAPRs) depending on fume type and concentration.

- Eye Protection: Safety glasses or goggles prevent irritation from smoke and particulates.

- Protective Clothing: Gloves and sleeves help avoid skin contact with fine dust when cleaning equipment or handling filters.

Monitoring and Maintenance

Even the best systems fail without consistent oversight. Regular monitoring and maintenance ensure long-term effectiveness:

- Air Quality Monitoring: Sensors can detect particulate and VOC levels, providing real-time safety data.

- Routine Inspections: Checking ducts, seals, and filters for leaks or blockages.

- Scheduled Filter Replacement: Based on usage hours or manufacturer recommendations.

- Record-Keeping: Tracking maintenance and exposure levels helps with compliance audits and ensures accountability.

Occupational Safety Standards and Regulations

OSHA (Occupational Safety and Health Administration)

OSHA enforces legally binding Permissible Exposure Limits (PELs) for specific substances found in laser cutting fumes:

- Hexavalent Chromium (Cr VI): 5 µg/m³ (8-hour time-weighted average, TWA).

- Formaldehyde: 0.75 ppm TWA, with a 2 ppm short-term exposure limit (STEL).

- General Particulates: OSHA requires limiting total and respirable dust exposure, even when substances are not specifically regulated.

ACGIH (American Conference of Governmental Industrial Hygienists)

Unlike OSHA, ACGIH publishes Threshold Limit Values (TLVs®), which are recommendations, not enforceable laws. However, they are widely regarded as industry best practices and often adopted into company safety policies:

- Nickel Compounds: TLV of 0.2 mg/m³ (inhalable fraction).

- Formaldehyde: TLV of 0.1 ppm.

- Particulates Not Otherwise Classified (PNOCs): TLV of 3 mg/m³ (respirable) and 10 mg/m³ (inhalable).

NIOSH (National Institute for Occupational Safety and Health)

NIOSH issues Recommended Exposure Limits (RELs) and recognizes welding and cutting fumes as occupational hazards. While not legally enforceable, RELs strongly influence workplace safety programs:

- Hexavalent Chromium: REL of 0.2 µg/m³, much stricter than OSHA’s PEL.

- Nickel and Cadmium Compounds: Classified as carcinogens with very low RELs.

- Formaldehyde: REL of 0.016 ppm (8-hour TWA).

EU Directives

In Europe, worker protection is guided by binding directives that member states must implement in national law:

- Directive 2004/37/EC: Covers carcinogens and mutagens at work, including formaldehyde, nickel, and hexavalent chromium.

- Directive 98/24/EC: Addresses the risks of chemical agents, requiring risk assessments and exposure minimization.

- Occupational Exposure Limits (OELs): Each EU country sets specific OELs, many of which align with or exceed ACGIH TLVs.

Local Environmental Agencies

In addition to national and international standards, local agencies often regulate emissions and waste from laser cutting:

- Air Quality Management Districts (U.S.): May restrict outdoor release of VOCs or particulates from industrial facilities.

- National Labor Ministries (non-EU countries): Implement country-specific standards for dust and chemical emissions.

- Waste Management Authorities: Oversee disposal of used filters and collected particulates, often classifying them as hazardous waste.

Best Practices for Safe Laser Cutting

Know Your Material

Different materials release different fumes.

- Check material specifications before cutting. Avoid especially hazardous options such as PVC, lead-coated metals, or unknown composites.

- Watch for coatings and adhesives, which may produce toxic gases not present in the base material.

- Material labeling and documentation help ensure operators know exactly what they are working with.

Use Proper Ventilation

Ventilation is the cornerstone of fume control.

- Local Exhaust Ventilation (LEV): Capture fumes directly at the cut source.

- General Ventilation: Provides background air exchange but should not replace LEV.

- Duct Design and Placement: Ensure capture points are close enough to prevent fumes from dispersing.

Maintain Equipment

A poorly maintained system quickly loses effectiveness.

- Replace filters (HEPA, carbon) on schedule—saturated filters allow contaminants to bypass.

- Inspect ducts and seals for leaks that can release fumes back into the workspace.

- Calibrate monitoring equipment to ensure accurate readings of air quality.

Provide PPE

Personal Protective Equipment (PPE) acts as the last line of defense.

- Respirators: N95, P100, or powered air-purifying respirators (PAPRs), depending on risk level.

- Eye Protection: Shields workers from smoke and particulate irritation.

- Gloves and Protective Clothing: Useful when cleaning residue or handling contaminated filters.

Train Workers

Knowledge is critical for safety.

- Hazard Recognition Training: Teach workers how to identify risky materials and cutting conditions.

- Safe Handling Procedures: Proper filter replacement, waste disposal, and machine maintenance.

- Emergency Response: Workers should know what to do in case of accidental fume release or equipment failure.

Comply with Regulations

Legal compliance ensures both worker protection and liability reduction.

- Follow OSHA, NIOSH, and EU exposure limits.

- Document safety practices for inspections and audits.

- Adopt stricter internal standards where recommended (e.g., ACGIH TLVs).

Monitor Air Quality

Continuous monitoring prevents hidden risks.

- Install sensors for particulates and VOCs near cutting stations.

- Conduct periodic sampling to measure actual worker exposure.

- Track data over time to detect trends and adjust controls proactively.

Consider Alternatives

Sometimes the safest option is to avoid high-risk processes altogether.

- Choose safer materials (e.g., acrylic instead of PVC).

- Use mechanical cutting methods for materials known to release extremely toxic emissions.

- Adopt cleaner technologies such as waterjet or plasma cutting in certain contexts.