What Do We Mean by “Hot”?

When people ask how hot laser welding is, they often mix up different kinds of “hot.” To be clear, we’ll separate five distinct zones and talk about what “hot” means in each:

- Beam–surface interface: a micro-thin skin where photons deposit energy. In conduction mode, this sits just above the alloy’s liquidus; in keyhole mode, tiny patches are driven to near or above the metal’s boiling temperature.

- Keyhole vapor (inside the cavity): a narrow, dynamic void stabilized by recoil pressure from evaporation. Temperatures here are above boiling for the base metal — it’s a localized, violently energetic region.

- Plasma plume above the pool: ionized vapor and shielding gas just above the weld pool. It’s thousands of kelvins, bright, and tiny. It may absorb or deflect some of the beam, especially with CO2 lasers.

- Molten pool: the bulk of the liquid metal. Most of it sits just above the liquidus; the hottest spots are at the keyhole walls and the trailing lip where flow circulates.

- Heat-affected zone (HAZ): solid metal around the pool that experiences a spectrum of peak temperatures, from a few hundred °C to just below liquidus at the fusion boundary.

Important clarifications:

- The laser isn’t a hot object. The beam is light. Heat appears only where absorption happens — mainly in the workpiece and, to a lesser extent, in the plume.

- A single numeric temperature doesn’t describe the weld. Each zone has its own range, and those ranges shift with process parameters and materials.

- Heat input isn’t temperature. It’s a useful metric (J/mm), but the peak temperatures and gradients depend on how energy is delivered (power density, dwell time, coupling).

Rough material context (typical ranges):

- Aluminum alloys: liquidus ~580–660 ℃; boiling ~2,400–2,500 ℃.

- Carbon and stainless steels: liquidus ~1,420–1,530 ℃; iron boils ~2,860 ℃.

- Titanium alloys: liquidus ~1,600–1,700 ℃; boiling ~3,300 ℃.

- Copper and copper alloys: liquidus ~1,000–1,085 ℃; boiling ~2,560 ℃.

- Nickel-base superalloys: liquidus ~1,250–1,350 ℃; nickel boils ~2,730 ℃.

How Laser Welding Makes Heat

Laser welding converts light into heat at the metal surface (and within a tiny optical skin depth). Three things happen when the beam hits:

- Reflection: a fraction of light bounces off, especially from clean, smooth, or highly reflective metals.

- Absorption: the rest is converted to heat within nanometers to micrometers of depth.

- Transmission: effectively zero for metals at industrial wavelengths.

Absorptivity, Wavelength, and Surface Condition

Absorptivity sets how much of the beam turns into heat. It depends on wavelength, polarization, angle, surface roughness, oxide films, and temperature.

- Near-IR fiber/disk (≈1.03–1.07 µm): strong absorption in steels and many alloys; moderate in aluminum; initially low in copper but rising fast with temperature and surface changes. This is today’s dominant industrial wavelength.

- CO2 (10.6 µm): historically important; effective for steels, but more prone to plasma absorption above the pool and typically requires different optics and longer focal lengths.

- Green/blue (≈515–532 nm / ≈450 nm): excellent initial coupling in copper, gold, and some reflective metals; helps stabilize keyholes and reduce spatter at lower average power.

- Surface condition matters: Oxides and roughness increase absorptivity. That can be helpful for coupling, but uncontrolled oxides can introduce inclusions or porosity. Cleanliness still matters.

Power Density and Dwell Time

For a Gaussian spot, peak irradiance depends on power divided by spot area. Shrinking the spot quickly boosts irradiance. Useful scales:

- Conduction-mode welding: ~10⁵–10⁶ W/cm².

- Keyhole-mode welding: typically ≥10⁶ W/cm². At this level, the surface hits near-boiling locally, vapor jets form, recoil pressure opens a cavity (keyhole), and coupling increases via multiple reflections.

Heat Flow vs. Temperature

The Temperature Map: Zone by Zone

Beam–Surface Interface

- Conduction mode (no sustained vaporization): the surface hovers just above the liquidus. Expect ~600–700 ℃ for aluminum alloys, ~1,450–1,600 ℃ for steels, ~1,050–1,150 ℃ for copper.

- Keyhole mode: the tiny area where the beam meets the advancing keyhole wall flashes to or above the boiling point of the metal. It’s a moving target, constantly renewed as the beam travels. This is what generates the recoil pressure that maintains the cavity.

Keyhole Vapor (Inside the Cavity)

Plasma Plume Above the Pool

Molten Pool

The pool isn’t at one temperature. Most of the liquid sits only slightly above liquidus, while narrow regions near the keyhole walls and the rear lip can approach local boiling.

- Aluminum pools: ~650–1,000 ℃ in bulk.

- Steel pools: ~1,500–1,900 ℃ in bulk.

- Copper pools: ~1,100–1,400 ℃ in bulk.

HAZ and Base Metal

Heat Input Isn’t Temperature (But It Drives It)

Heat input is the energy per unit length of weld. In practical terms: take the fraction of laser power that actually enters the work (process efficiency), multiply by the laser power, then divide by travel speed.

- η varies with mode, material, wavelength, and shielding. In conduction mode, you might see ~0.3–0.6; in keyhole mode, multiple reflections inside the cavity often raise η to ~0.6–0.9.

- Same H, different temperatures: You can achieve the same J/mm with low power/slow speed or high power/fast speed. The peak temperatures and gradients will differ because the irradiance and dwell time differ.

Conduction vs. Keyhole Mode: Why the “Hotness” Feels Different

Laser welding runs in two broad regimes:

- Conduction mode: Below the keyhole threshold. The surface melts; energy spreads by conduction; penetration is limited (often ≤1 mm in many alloys). The pool is calm, the surface glossy, and spatter is minimal. Peak temperatures hover around liquidus — hot enough to melt, not hot enough to sustain evaporation.

- Keyhole mode: Above the threshold. Localized near-boiling kicks off evaporation; recoil pressure opens a cavity. Multiple reflections in the keyhole increase absorption, so you get deep penetration with a small surface footprint. Peak local temperatures are higher at the keyhole wall. Spatter, porosity, and undercut become risks if the keyhole is unstable.

What Controls “How Hot?”

Laser Power and Duty Cycle

- Average power sets the overall energy available. More power at the same speed raises heat input and can support deeper penetration.

- Pulsed operation concentrates energy into short bursts with high peak power. A 200 W average pulsed laser can deliver multi-kilowatt peaks briefly, punching above its weight to cross the keyhole threshold without overheating the part overall. Pulse shaping (pre-heat, peak, tail) lets you control how fast the surface ramps toward boiling.

Spot Size and Focus (Focal Position)

- Smaller spots raise irradiance dramatically (irradiance rises sharply as the spot shrinks (halve the spot, roughly quadruple it)). Tight focus drives the surface hotter, faster.

- Focal position matters: focusing slightly below the surface often stabilizes a keyhole by putting peak irradiance where the cavity forms. Too much negative focus can over-energize the rear wall and destabilize the keyhole; too much positive focus (above the surface) softens irradiance and collapses penetration.

- Beam quality (M²), lens choice, and optics cleanliness all change the real spot you get, which changes how hot the interface runs.

Travel Speed

- Slower travel increases dwell time, inflating the pool and HAZ and allowing higher peak temperatures.

- Faster travel shrinks everything but demands higher irradiance to maintain penetration. That combination — high irradiance, short dwell — is how laser welding achieves deep welds with low overall heat input.

Wavelength

- 1 µm (fiber/disk): workhorse wavelength; strong coupling to steels; adequate for aluminum with enough power density; marginal on cold, shiny copper, but workable as it heats.

- 6 µm (CO2): capable but more sensitive to plasma absorption; requires different beam delivery optics and longer focal lengths.

- Green/blue: shine on copper and precious metals. They reduce the “cold start” reflectivity problem and stabilize keyholing at lower average powers.

Shielding Gas

- Argon: common and dense; good coverage; can promote a thicker plume at high irradiance.

- Helium: higher ionization potential suppresses plasma absorption; useful at high power or with reflective metals; lighter and more expensive.

- Nitrogen: useful for some austenitic stainless steels (can improve pitting resistance by nitrogen pick-up); avoid with ferritic steels, where nitrides can embrittle.

- Flow rate, nozzle distance, and angle shape the plume and affect how much of the beam reaches the surface.

Joint Geometry and Fit-Up

- Butt, lap, and fillet joints present different heat sinks and reflection traps. Tight fit-up conducts heat away efficiently; gaps force the keyhole to bridge voids, raising local temperatures and spatter risk.

- Backings (copper shoes, chill bars) pull heat and shape the pool bottom; they can prevent burn-through in thin sheet while allowing higher peak temperatures on top.

Base-Metal Properties

- Thermal conductivity: aluminum and copper wick heat away quickly; steels and titanium conduct more slowly.

- Reflectivity: copper and fresh, polished aluminum reflect strongly at 1 µm when cold; absorption climbs as they heat and oxidize.

- Latent heats: metals with high latent heats require more energy to melt and especially to vaporize; this influences how fast you can launch into keyholing and how violent the plume becomes.

Material-By-Material: What “Hot” Looks Like

Carbon and Low-Alloy Steels

- Temperature landscape: liquidus ~1,420–1,530 ℃; local boiling near iron’s ~2,860 ℃ in the keyhole interface. HAZ spans a wide range: 200–800 ℃ (tempering), 900–1,350 ℃ (austenitizing), up to just below liquidus at the fusion boundary.

- Process feel: easy coupling at 1 µm; stable keyholing over a wide window. Spatter rises when irradiance is excessive or shielding is poor.

- Metallurgy: rapid cooling (10³–10⁶ K/s) can create martensite in hardenable steels. Control hardness and cracking with preheat, interpass temperature, and post-weld temper when needed.

- Practical cues: a calm, narrow plume; consistent penetration; minimal undercut when focus is placed slightly sub- If the plume roars and blows spatter, you’re running too hot at the front wall.

Stainless Steels (Austenitic, Ferritic, Duplex)

- Temperatures: liquidus roughly 1,380–1,500 ℃ depending on grade. The pool runs just above that, with higher local peaks in keyhole mode.

- Flow quirks: trace elements (S, O) can flip Marangoni flow from outward to inward, changing bead shape. Cleaning and controlled sulfur/oxygen content matter.

- Metallurgy: avoid excessive heat input on austenitics to reduce sensitization (chromium carbide precipitation). Duplex grades need balanced heat input to hit the correct austenite/ferrite ratio.

- Shielding: consider nitrogen for some austenitics; avoid on ferritics where nitrides embrittle.

Aluminum Alloys (1xxx–7xxx)

- Temperatures: liquidus ~580–660 ℃; boiling ~2,470 ℃. Despite the low melting point, reaching and stabilizing the keyhole requires high irradiance because aluminum reflects and conducts heat aggressively.

- Defects: porosity (hydrogen), keyhole instability, and hot cracking (especially in high-Mg or high-Cu alloys). Clean, dry surfaces and shielding gas are non-

- Process strategies: use high peak power or green/blue wavelengths for easier keyholing; pulse shaping with a long tail to let gases escape; wobble to increase lateral fusion without spiking local temperature.

- Fillers: tailored filler (e.g., 4xxx/5xxx families) reduces crack sensitivity and manages composition.

Copper and Copper Alloys

- Temperatures: liquidus ~1,000–1,085 ℃; boiling ~2,560 ℃. Cold copper is a mirror at 1 µm and a gigantic heat sink.

- Coupling: green/blue lasers excel here. At 1 µm, preheating, roughening, or using very high peak power to “break through” initial reflectivity can stabilize the process. Once hot, absorptivity rises and the weld “locks in.”

- Shielding: helium often outperforms argon at high power by thinning the plasma and improving coupling.

- Defects: spatter from violent evaporation, lack of fusion when the keyhole collapses, porosity if gases are trapped during ultra-fast solidification.

Titanium Alloys

- Temperatures: liquidus ~1,600–1,700 ℃; boiling ~3,300 ℃. Titanium couples well at 1 µm.

- Reactivity: at high temperatures, titanium grabs oxygen and nitrogen readily. Use excellent shielding (trailing shoe, gas chamber, or glove box). A bright silver or straw color indicates good shielding; blue/gray suggests overheating or contamination.

- Metallurgy: manage heat input to control microstructure (α/β balance). Cooling is fast; avoid excessive hardness or residual stress in thick sections with preheat and controlled restraint.

Nickel-Base Superalloys

- Temperatures: liquidus ~1,250–1,350 ℃; boiling (Ni) ~2,730 ℃.

- Process: small pools, narrow windows. Many grades are crack-sensitive (strain-age cracking, liquation). Control heat input and solidification path; use compatible fillers and, where needed, preheat.

- Application: laser’s small HAZ and focused heat can be an advantage for repair and additive processes, provided metallurgy is respected.

Magnesium and Reactive Metals

- Magnesium: melts at ~650 ℃ and is highly reactive and volatile. Keep shielding strong and parameters tight to avoid spatter and oxidation.

- Zirconium/Tantalum/Niobium: extremely reactive when hot; demand immaculate shielding and cleanliness. The metal itself is not “too hot” per se, but contamination at high temperatures will ruin properties.

Pulse, Wobble, and Hybrid: Shaping How Heat Arrives

Pulsed Laser Welding

Pulsing concentrates energy into short bursts. During the pulse, peak power can exceed the steady-state keyhole threshold; between pulses, the pool relaxes. Benefits:

- Achieve penetration with lower average heat input, reducing distortion.

- Pulse shaping (pre-heat foot, peak, tail) lets you moderate how quickly the surface ramps toward boiling, reducing spatter and porosity.

- Micro-welding and electronics: fine control over melt size and minimal HAZ.

Wobble (Beam Oscillation)

Oscillating the beam (Lissajous, circular, figure-eight) spreads energy laterally. This:

- Stabilizes the keyhole by avoiding a single extreme hot spot.

- Increases lateral fusion to handle gaps and misalignment.

- Lets you run higher speeds without losing fusion because the energy is distributed over a controlled width.

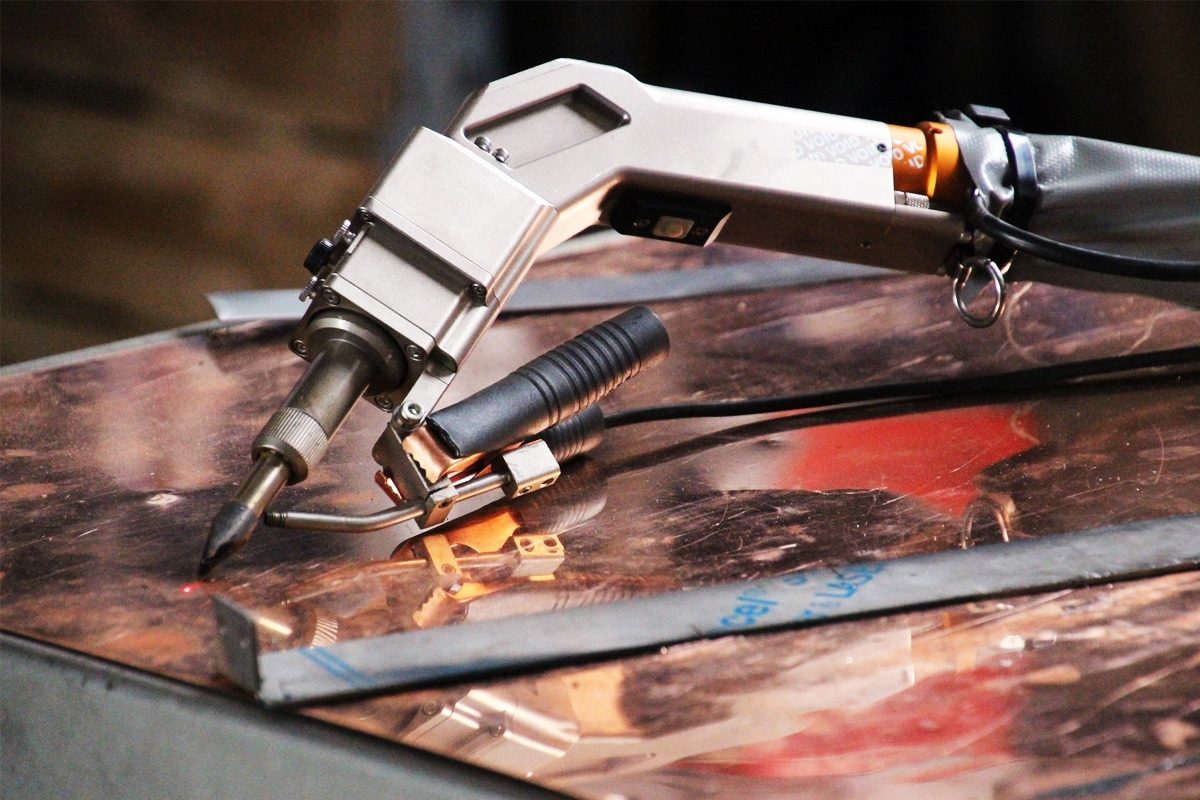

Laser-Arc Hybrid Welding

Benefits:

- Deep, fast welds with wire feed for composition control and gap bridging.

- Lower distortion than pure arc for equivalent thickness.

- Tunable “hotness distribution”: the laser drives depth; the arc wets edges and fills.

Cooling Rates

Laser welding produces extreme thermal gradients and very fast cooling once the beam passes — often in the 10³–10⁶ K/s range. This matters because the cooling rate drives:

- Microstructure: martensite formation in hardenable steels; dendrite arm spacing in aluminum; γ′ evolution in nickel alloys; α′ in titanium.

- Residual stress: low total heat input reduces distortion, but steep gradients lock in high local stresses if joints are heavily restrained.

- Defects: fast solidification can trap gas (porosity) or create hot tears in susceptible alloys. Process stability during the hot phase is key; a stable keyhole is often less porous than a marginal, “cooler” one.

Practical Numbers and Back-of-Envelope Estimates

Keyhole Threshold Check

Take a 1 kW laser focused to a 100 µm diameter spot (w ≈ 50 µm):

- At those settings, the peak irradiance is about 2.5×10⁶ W/cm², firmly in keyhole territory for many alloys.

Heat Input vs. Distortion

Two parameter sets with the same heat input can behave very differently:

- Setup A: 3 kW at 3 m/min (50 mm/s), η=0.8 → H≈48 J/mm. High irradiance, short dwell: hotter surface briefly, narrow HAZ, deep penetration.

- Setup B: 1.5 kW at 1.5 m/min (25 mm/s), η=0.8 → H≈48 J/mm. Lower irradiance, longer dwell: wider HAZ, lower peak surface temperature, similar distortion but different bead shape.

Full-Penetration Rule of Thumb (Thin Sheet)

Other quick checks:

- If the plume forms and remains steady with little spatter, you’re near a stable keyhole.

- If penetration wanders at constant settings, suspect focus drift, shielding, or absorptivity changes (contamination/oxide).

- If oxide colors march far from the bead on stainless or titanium, your peak temperatures and time-at-temperature are too high, or shielding is weak.

Managing the “Too Hot / Not Hot Enough” Problems

Not Hot Enough (Lack of Fusion, Shallow Penetration)

- Increase power or reduce speed.

- Tighten focus (smaller spot) and/or move focus slightly below the surface for keyhole work.

- Improve absorption: clean and dry the surface; consider green/blue for copper; use helium or He-rich mixes at high power to thin the plume.

- Reduce heat sinks: close gaps, support the joint with backing, and avoid massive clamps close to the seam.

Too Hot (Excess Spatter, Undercut, Porosity, Burn-Through)

- Back off-peak irradiance or shift from keyhole toward conduction if the application allows.

- Use pulse shaping (gentler ramp-in, longer tail) or wobble to soften the launch into keyholing and distribute energy.

- Adjust focus position; focusing too far below the surface over-energizes the rear wall and destabilizes the keyhole.

- Improve shielding to reduce oxidation that triggers violent evaporation and spatter.

Porosity in Aluminum and Copper

- Ensure dry, clean surfaces and shielding gas; avoid hydrocarbons and moisture.

- Keep the keyhole stable: err slightly “hotter but stable” rather than “cool and collapsing.”

- Shape pulses with a long tail to give bubbles time to escape before the pool freezes.

- Consider preheating thick sections to reduce gradients and collapse time.

Hot Cracking

- Choose a compatible filler to adjust the solidification range and reduce crack sensitivity.

- Control solidification rate by modestly increasing heat input or preheating restrained joints.

- Minimize contaminants (S, P) that widen the solidification range and embrittle grain boundaries.

Comparing “Hotness”: Laser vs. Arc vs. Electron Beam

- Gas Tungsten Arc (GTAW/TIG) and Gas Metal Arc (GMAW/MIG): arc cores run ~8,000–20,000 K — far hotter as plasmas than a laser plume — but the energy spreads over a much larger area. Pools are bigger, HAZs wider, and total heat input is higher for the same penetration.

- Laser: smaller spot, extreme power density, near-boiling at the keyhole interface in a microscopic region. Deep penetration with lower total heat input and narrower HAZ.

- Electron Beam (EBW): like laser keyhole, but with electrons in a vacuum. Enormous energy density and coupling; very deep penetration. Local metal temperatures at the keyhole interface also reach near-boiling; overall heat input is comparable or lower than that of the laser for the same depth, but vacuum and part size constraints apply.

Safety

Laser welding compresses dangerous amounts of energy into tiny spaces. Treat the system like a live furnace with invisible flames.

- Eye and skin safety: near-IR beams are invisible and can permanently damage eyes. Use interlocked enclosures and eyewear rated for your wavelength and power. Protect skin from reflections and spatter.

- Specular reflections: shiny copper/aluminum can bounce significant power. Eliminate line-of-sight reflections; use beam dumps and non-reflective fixtures.

- Fume and plume: hot metal vapor creates fine oxides and nanoparticles. Capture and filter at the source. Never weld without adequate ventilation.

- Fire risk: the plume is hot enough to ignite nearby combustibles. Keep the area clear; don’t underestimate how far spatter can travel.

- Gas safety: helium cylinders, argon, and nitrogen displace oxygen; manage asphyxiation risk in enclosed spaces.

- Thermal burns and hot parts: treat anything near the weld as hot until proven otherwise. Use tools, not hands, to handle recent welds and coupons.

Summary

There isn’t one number that answers “How hot is laser welding?” The honest answer is a map of temperatures:

- The beam–surface interface runs at liquidus in conduction mode and near/above boiling in keyhole mode.

- The keyhole vapor is superheated above boiling, generating recoil pressure that opens the cavity and pumps energy deep.

- The plasma plume above the pool sits at thousands of kelvins in a tiny volume; it can steal or deflect light if unmanaged.

- The molten pool sits just above the liquidus, with local peaks near the keyhole wall.

- The HAZ ranges from a few hundred ℃ to just under the liquidus, depending on distance and dwell.