Fundamentals of Laser Cleaning

What is Laser Cleaning

Applications include:

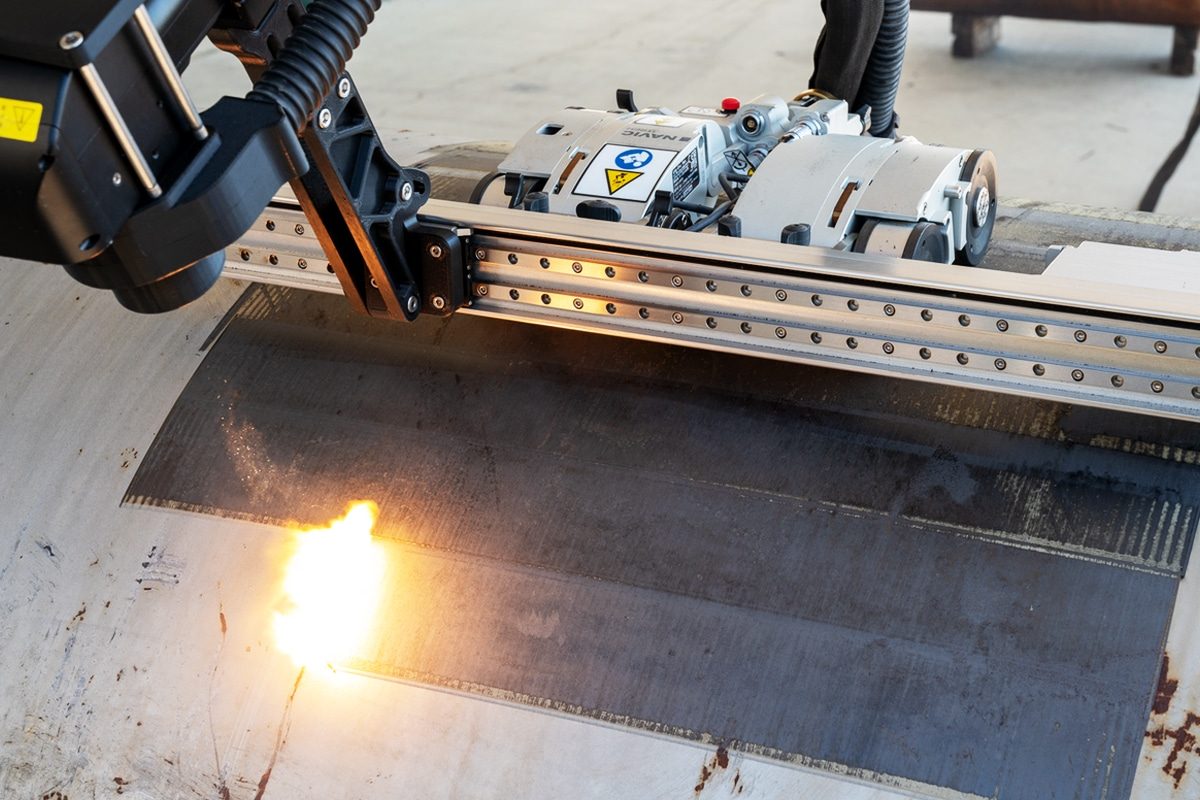

- Industrial Manufacturing: Removing oxides before welding, stripping paint before recoating, and preparing surfaces for bonding.

- Electronics: Cleaning printed circuit boards or delicate semiconductor parts.

- Cultural Heritage: Removing corrosion or pollution residues from stone, metal, or artwork without chemical exposure.

- Nuclear Industry: Decontaminating radioactive surfaces without generating hazardous liquid waste.

Principles of Operation

The effectiveness of laser cleaning depends on laser–material interaction. When a pulsed laser beam strikes the surface, the contaminant absorbs light differently than the substrate due to differences in optical absorption coefficients. This selective absorption creates one or more of the following effects:

- Localized Heating: The contaminant heats rapidly, causing melting or vaporization.

- Thermal Expansion mismatch: Different thermal responses between layers lead to stress and delamination.

- Bond Weakening: High photon energy may break bonds between contaminant and substrate.

Key laser parameters influencing cleaning include:

- Wavelength: Determines absorption efficiency (e.g., rust absorbs more strongly in IR than bare steel).

- Pulse Duration: Nanosecond, picosecond, or femtosecond pulses dictate whether cleaning is thermal (slow heating) or non-thermal (cold ablation).

- Fluence (J/cm²): The energy delivered per area; it must exceed the removal threshold but stay below the substrate damage threshold.

- Repetition Rate & Scanning Speed: Control how much cumulative energy the surface receives.

Types of Laser Cleaning Systems

Solid-State Laser

- Nd:YAG lasers: Early workhorses in laser cleaning, offering good efficiency and reliability.

- Fiber lasers: Currently the most widely adopted due to compact design, excellent beam quality, high power, and flexible fiber delivery systems.

Gas Lasers

- CO2 lasers (10.6 μm): Effective for non-metallic surfaces (polymers, ceramics), but less common for metals due to weaker absorption.

- Excimer lasers (UV, 193–351 nm): Short wavelengths allow precise, shallow cleaning of thin films and organic contaminants with minimal heat damage.

Pulsed VS. Continuous-Wave (CW) Lasers

- CW lasers: Provide constant energy, but are less common in cleaning due to the risk of substrate overheating.

- Pulsed lasers: Dominant in cleaning applications.

- Nanosecond pulses: Common for industrial rust/oxide removal.

- Picosecond/femtosecond pulses: Provide “cold ablation,” minimizing heat effects and suitable for delicate surfaces like microelectronics or heritage artifacts.

Mechanisms of Material Removal

The removal process is governed by one or more physical mechanisms, depending on the contaminant, substrate, and laser parameters:

- Photothermal Ablation

- Laser energy is absorbed and converted into heat.

- The contaminant vaporizes or melts, detaching from the substrate.

- Common in oxide and paint removal.

- Photomechanical Effects

- Rapid heating produces thermal expansion and shock waves.

- These stresses fracture brittle layers or eject particles.

- Particularly effective for rust flakes or surface particulates.

- Photochemical Reactions

- High-energy photons (especially UV lasers) directly break molecular bonds.

- Useful for organic films, polymers, and delicate cleaning tasks.

- Optical Breakdown and Plasma Formation

- At very high intensities, the laser induces plasma above the surface.

- The expanding plasma creates micro-shockwaves, blasting away contaminants.

- Often seen with ultrashort-pulse lasers.

Importance of Surface Roughness and Cleanliness

Surface Roughness

Surface roughness is a measure of the fine irregularities present on a material’s surface. It is commonly quantified by parameters such as Ra (arithmetical mean roughness), Rz (average maximum height of profile), or Sa (arithmetical mean height in 3D). Roughness directly affects a component’s mechanical, tribological, and functional properties:

- Adhesion and Coating Performance: Slightly rough surfaces can improve the adhesion of paints, coatings, and adhesives by providing anchor points. However, excessive roughness can weaken bonds due to stress concentrations.

- Friction and Wear: Higher roughness usually increases friction and accelerates wear, while smoother surfaces reduce contact resistance in sliding applications.

- Fatigue Resistance: Sharp peaks and valleys in rough surfaces act as stress concentrators, lowering fatigue life and crack resistance.

- Corrosion Behavior: Rough surfaces may trap moisture or corrosive agents, accelerating localized corrosion, whereas smoother surfaces are easier to passivate and protect.

Surface Cleanliness

Surface cleanliness refers to the degree to which a substrate is free from unwanted materials such as oxides, dust, oils, grease, salts, or chemical residues. Cleanliness plays a critical role in processes where surface integrity directly impacts performance:

- Welding and Brazing: Oxides and contaminants interfere with metallurgical bonding, leading to weak joints, porosity, or incomplete fusion.

- Adhesive Bonding and Coating: Residues or films can act as release agents, preventing adhesion and causing premature delamination or coating failure.

- Electrical and Electronic Applications: Dust or oxide films increase electrical resistance, impair conductivity, or create short circuits in microelectronic devices.

- Corrosion Resistance: Residual contaminants may act as corrosion initiation sites, accelerating material degradation in aggressive environments.

How Laser Cleaning Affects Surface Roughness

Minimal Mechanical Damage

Parameter-Dependent Effects

The effect of laser cleaning on roughness is strongly influenced by process parameters:

- Laser Fluence (energy per unit area): If fluence is slightly above the ablation threshold, contaminants can be removed with little impact on the substrate. At higher fluences, melting or ablation of the base material may increase roughness.

- Pulse Duration: Nanosecond lasers may produce thermal effects such as melting and recast layers, increasing roughness. Ultrashort pulses (picosecond/femtosecond) typically remove material through non-thermal processes, maintaining smoother surfaces.

- Repetition Rate and Overlapping: High repetition rates or excessive overlap of laser spots can lead to localized heating, roughening, or micro-cracking.

- Wavelength: Shorter wavelengths (e.g., UV lasers) allow higher precision, reducing the risk of roughness alteration compared to infrared lasers.

Roughness Modification

Laser cleaning can either increase or decrease surface roughness, depending on the context:

- Increase in Roughness: Localized ablation, micro-pitting, or thermal melting may create rougher textures. In some cases, this is desirable—for instance, slightly roughened surfaces can improve coating adhesion or paint bonding.

- Decrease in Roughness: On some metallic surfaces, laser-induced melting and resolidification can “smooth out” sharp peaks, reducing roughness. This effect has been observed in certain alloys where molten material redistributes across valleys.

Material-Dependent Response

The substrate material plays a central role in determining how roughness is affected:

- Metals (e.g., steel, aluminum, titanium): Generally robust under laser cleaning, but may show micro-pitting or recrystallization at higher fluences. Aluminum, with its high reflectivity, may require higher energy, increasing the risk of surface modification.

- Polymers: More sensitive to thermal input. Even low-energy laser cleaning can cause localized melting, swelling, or chemical degradation that alters roughness.

- Ceramics and Composites: Typically resistant to mechanical wear, but thermal stresses from laser pulses can cause microcracks or uneven surface textures.

- Cultural Heritage Materials (stone, artwork, bronze): Require low-energy, short-pulse lasers to avoid noticeable roughness changes while still removing deposits.

How Laser Cleaning Affects Surface Cleanliness

High Degree of Cleanliness

One of the defining advantages of laser cleaning is its capacity to completely remove surface contaminants such as oxides, paint layers, corrosion products, grease, oils, and dust. Because the laser beam can be tuned to target the contaminant’s absorption properties while sparing the substrate, the process is selective and efficient.

- Oxide Removal: Oxide films that interfere with welding or coating adhesion can be precisely eliminated.

- Paint Stripping: Multi-layer coatings can be ablated without damaging the underlying metal.

- Grease and Hydrocarbons: Organic contaminants are effectively decomposed and vaporized under laser irradiation.

Avoidance of Residues

Surface Activation

Laser cleaning not only removes contaminants but can also activate the surface by modifying its chemistry in beneficial ways. Exposure to laser energy may increase the surface energy of the substrate, enhancing wettability and adhesion. For example:

- Improved Bonding: Activated surfaces promote stronger adhesion for coatings, paints, and adhesives.

- Enhanced Welding Performance: Removal of oxides combined with surface activation improves metallurgical bonding in laser or arc welding.

- Better Coating Uniformity: Increased surface energy ensures even spreading of paints or protective layers.

Micro-Level Cleanliness

A key advantage of laser cleaning is its ability to operate at the micro- and nano-scale. Unlike mechanical cleaning, which is limited by abrasive grain size, lasers can remove ultrathin films, monolayers, or fine particulates. This is especially critical for high-tech applications:

- Microelectronics: Removal of submicron particles and thin films that could interfere with conductivity or lithography.

- Optical Components: Cleaning of delicate lenses, mirrors, or sensors without introducing scratches.

- Cultural Heritage: Precise removal of dirt layers or corrosion products from artworks or historical objects without altering fine details.

Advantages of Laser Cleaning for Surface Quality

Superior Cleanliness

No Secondary Waste

Surface Activation

A unique benefit of laser cleaning is its ability not only to clean but also to activate the substrate surface. The laser energy can modify the chemical composition and increase the surface free energy, leading to:

- Improved adhesion of coatings, adhesives, and paints.

- Enhanced weldability, due to the removal of oxides combined with fresh surface exposure.

- Better corrosion resistance, as coatings applied to activated surfaces adhere more uniformly and protect more effectively.

Eco-Friendly and Safe

Highly Controllable

Limitations of Laser Cleaning for Surface Quality

Parameter Sensitivity

Laser cleaning is highly sensitive to process parameters such as wavelength, fluence, pulse duration, scanning speed, and repetition rate. Even slight deviations from optimal settings can significantly impact surface quality:

- Overexposure: Excessive fluence or overlapping laser passes may cause melting, micro-pitting, or cracking, leading to increased roughness.

- Underexposure: Insufficient energy may fail to remove contaminants completely, leaving residues that compromise cleanliness.

- Thermal Effects: Longer pulse durations or high repetition rates can induce thermal accumulation, altering surface morphology.

Material-Specific Effects

Different materials respond to laser cleaning in distinct ways, which can complicate process standardization:

- Metals: Generally robust, but highly reflective materials (like aluminum or copper) require higher laser fluence, increasing the risk of roughness changes.

- Polymers: Prone to thermal damage, discoloration, or chemical degradation if not carefully controlled.

- Ceramics and Composites: May experience microcracking or localized spallation due to rapid thermal expansion.

- Cultural Heritage Materials: Extremely sensitive to over-cleaning; excessive energy can irreversibly alter patina or fine details.

Cost of Equipment

Operator Expertise

Although laser cleaning is automated in many setups, it still requires skilled operators and engineers who understand laser–material interactions. Effective operation involves:

- Selecting the correct laser parameters for a given contaminant-substrate pair.

- Monitoring cleaning progress in real time to avoid substrate damage.

- Ensuring safety protocols are followed, as laser beams pose risks to the eyes and skin.

Industrial Applications and Requirements

Aerospace Industry

The aerospace sector demands the highest levels of reliability and safety, with surface quality being non-negotiable.

- Applications: Oxide removal before welding, cleaning of turbine blades, preparation of bonding surfaces for composites, and stripping of protective coatings.

- Requirements:

- Surfaces must remain smooth and fatigue-resistant to prevent crack initiation.

- Oxide-free surfaces are essential for strong welds and adhesive bonds.

- Residue-free cleaning is crucial, as even trace contaminants can cause premature failure under cyclic loading.

Automotive Industry

The automotive industry prioritizes speed, cost-efficiency, and durability in cleaning processes.

- Applications: Pre-treatment of car body panels before painting, rust and oxide removal before spot welding, and cleaning of molds or dies in production lines.

- Requirements:

- Surfaces must exhibit consistent roughness to ensure uniform paint adhesion.

- Cleaning must be fast and scalable to match high production throughput.

- Processes must minimize waste and consumables for cost-effectiveness.

Electronics Industry

In the electronics sector, even microscopic contamination can cause failure.

- Applications: Cleaning of printed circuit boards (PCBs), removal of oxides from electrical contacts, and precision cleaning of semiconductor wafers.

- Requirements:

- Micro-and nano-level cleanliness is critical to maintain conductivity and prevent short circuits.

- Surfaces must remain smooth and undamaged, as excessive roughness can alter electrical pathways.

- Processes must be dry and residue-free, since moisture or chemicals can compromise sensitive components.

Medical Device Manufacturing

Medical devices operate in direct contact with the human body, where biocompatibility and sterility are essential.

- Applications: Cleaning and preparation of implants (titanium, stainless steel), surgical instruments, and drug-delivery devices.

- Requirements:

- Surfaces must be completely free from contaminants, especially organics and residues that could trigger rejection or infection.

- Controlled roughness is sometimes required—for example, slightly roughened titanium surfaces enhance osseointegration of implants.

- Cleaning must comply with strict regulatory standards such as the FDA and ISO.

Cultural Heritage Conservation

In conservation, the priority is preservation without altering the original material.

- Applications: Removal of corrosion from bronze statues, pollution deposits from stone monuments, and overpaint or varnish from historical artworks.

- Requirements:

- Surfaces must retain their original microtexture and patina, which are often part of historical authenticity.

- Cleaning must be selective, removing dirt or corrosion while sparing the underlying artwork.

- Processes must be non-invasive, residue-free, and reversible wherever possible.

Optimizing Laser Cleaning Parameters

Laser Power and Fluence

- Definition: Laser power is the energy output per unit time, while fluence is the energy delivered per unit area (J/cm²).

- Impact:

- Too low → contaminant not fully removed, leaving residues.

- Too high → substrate ablation, melting, or micro-pitting, increasing surface roughness.

- Optimization: Fluence must exceed the contaminant’s ablation threshold but remain below the substrate’s damage threshold. For example, rust removal from steel typically requires 1–5 J/cm², while delicate polymer cleaning may need sub-J/cm² fluence levels.

Pulse Width

- Definition: The duration of each laser pulse (nanoseconds, picoseconds, femtoseconds).

- Impact:

- Nanosecond pulses: Longer interaction → thermal effects (melting, recast layers) → possible increase in roughness.

- Picosecond/femtosecond pulses: Ultra-short interaction → “cold ablation” (minimal heat diffusion) → preserves smoothness and microstructure.

- Optimization: For industrial cleaning (rust, paint), nanosecond pulses are often sufficient. For high-value applications (electronics, medical, heritage), shorter pulses prevent thermal damage.

Wavelength Selection

- Definition: The laser wavelength determines absorption efficiency between the contaminant and substrate.

- Impact:

- Infrared (e.g., fiber laser, 1064 nm): Well-suited for rust and oxides on metals.

- UV (excimer, 193–351 nm): Strong absorption by organics → ideal for delicate films, polymers, or microelectronics.

- CO2 (10.6 μm): Effective for non-metallic surfaces (ceramics, plastics).

- Optimization: Selecting the correct wavelength ensures contaminants absorb energy preferentially, minimizing substrate heating and roughness modification.

Scanning Speed

- Definition: The velocity at which the laser beam moves across the surface.

- Impact:

- High speed: Less energy per unit area → insufficient cleaning.

- Low speed: Excessive local heating → surface roughening, microcracks, or oxidation.

- Optimization: Must balance throughput and quality. Automated systems often use adjustable galvanometer scanners or robotic arms to maintain uniform cleaning with controlled overlap.

Number of Passes

- Definition: The number of times the laser scans over the same area.

- Impact:

- Single-pass cleaning: May not fully remove thick contaminants.

- Multiple passes: Improves cleanliness but increases the risk of thermal accumulation and surface modification.

- Optimization: A stepwise approach is often used—start with conservative parameters and add passes as needed to ensure full contaminant removal while avoiding surface damage.

Assist Gases

- Definition: Inert or reactive gases used during cleaning to influence efficiency and surface outcomes.

- Impact:

- Inert gases (e.g., argon, nitrogen): Prevent oxidation, cool the surface, and aid in debris removal.

- Reactive gases (e.g., oxygen): Can enhance the removal of carbonaceous materials but may introduce oxidation if uncontrolled.

- Optimization: Choice depends on application—argon/nitrogen are preferred for precision cleaning, while oxygen may be used for stubborn organic contaminants.