Are There Any Challenges With Laser Cutting Technology?

Laser cutting is one of the most transformative technologies of modern manufacturing. It combines precision, speed, and versatility, making it indispensable in industries such as aerospace, automotive, medical devices, and consumer electronics. The ability to cut complex geometries quickly, with minimal waste, has pushed manufacturers to adopt laser cutting systems worldwide. Yet, despite its reputation as a near-perfect process, laser cutting is far from flawless. Challenges exist at nearly every stage, from selecting the right material to maintaining equipment, managing operating costs, and ensuring worker safety. These hurdles often determine whether a laser cutting operation is profitable, sustainable, and capable of meeting strict industry standards. In this article, we examine the challenges in detail, offering a comprehensive exploration that spans the technical, material, operational, and economic dimensions of laser cutting technology.

Table of Contents

Understanding Laser Cutting

What Is Laser Cutting?

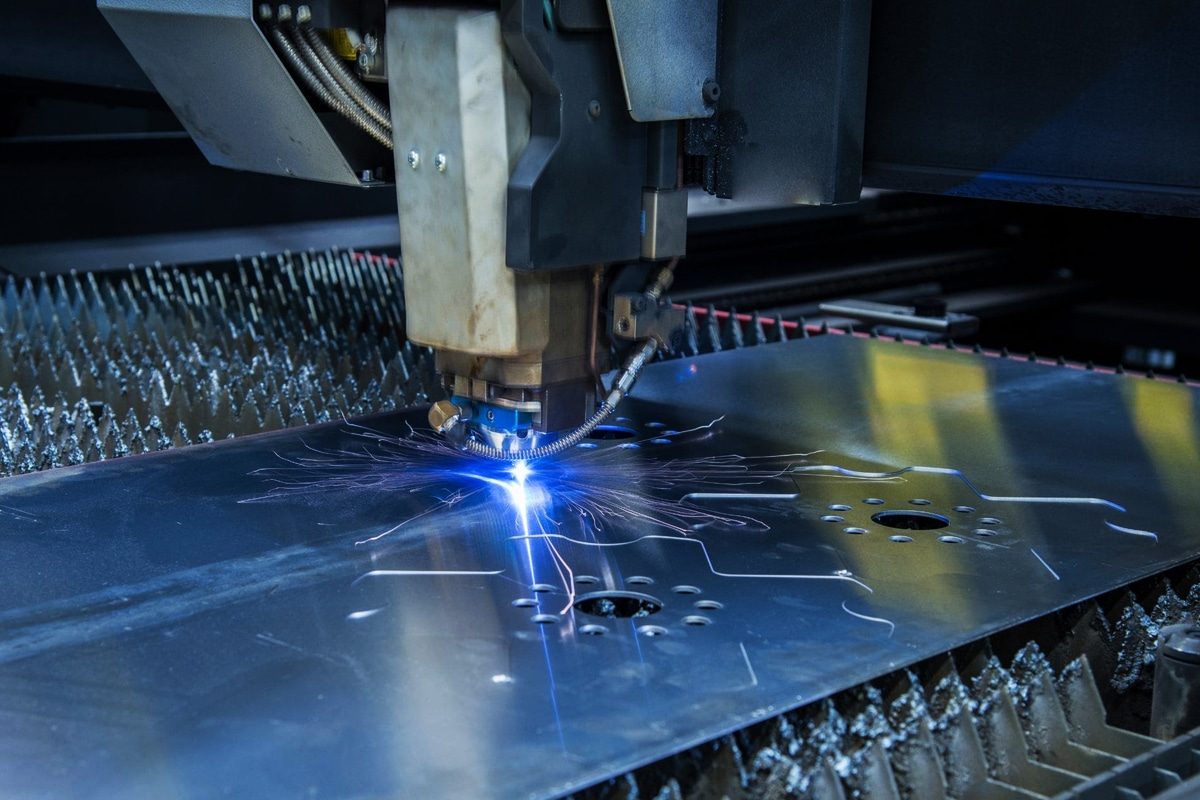

Laser cutting is a subtractive process that uses a concentrated beam of light to cut, mark, or engrave materials. Unlike mechanical processes, the laser does not physically contact the workpiece. Instead, it relies on thermal energy to vaporize, burn, or melt the material, assisted by a jet of gas to clear debris. This makes it possible to achieve cuts with micron-level accuracy.

How Does It Work?

The process begins with a laser source, such as a CO2 resonator or fiber system. Mirrors or fiber optics direct the beam toward a focusing lens, which concentrates it to a small point. At this point, the energy density is extraordinarily high, often reaching levels that exceed millions of watts per square centimeter. The material surface absorbs the energy, causing localized melting or vaporization. Assist gases, like oxygen or nitrogen, blow the molten material out of the kerf and influence the chemical interactions at the cutting zone. The result is a precise and often clean cut.

Types of Laser Cutting Systems

- CO2 Lasers: Long-established, versatile machines suitable for cutting non-metals such as wood, plastics, and textiles, as well as mild steel. They are less effective with reflective metals and require more maintenance than fiber lasers.

- Fiber Lasers: Highly efficient systems that excel at cutting metals, including reflective materials such as aluminum and copper. Fiber lasers have become the dominant choice in industrial applications due to lower operating costs and longer lifespans.

- Nd:YAG Lasers: Used in specialized applications such as drilling and welding, where high peak power is essential. While less common for sheet cutting, they play an important role in niche industries.

Materials Suitable for Laser Cutting

Laser cutting works on metals (carbon steel, stainless steel, aluminum, titanium, copper, brass, galvanized steel, nickel alloy), plastics (acrylic, polycarbonate, polypropylene), wood, ceramics, glass, textiles, and composite materials. However, not all materials respond equally well, and their thickness, reflectivity, or chemical composition can significantly influence cut quality and process safety.

Advantages of Laser Cutting

- Exceptional precision and repeatability

- Capability to cut intricate and complex geometries

- Reduced material wastage due to optimized nesting and thin kerf

- Non-contact process reduces tool wear and mechanical stress

- Speed and efficiency in thin to moderately thick materials

- Flexibility to switch between different materials with limited setup time

Disadvantages of Laser Cutting

- High capital investment for advanced machines

- Limited efficiency with very thick plates compared to plasma or waterjet cutting

- Reflective materials can damage optical components

- Heat-affected zones may alter metallurgical properties

- Operational hazards, including toxic fumes, fire risks, and radiation exposure

Application of Laser Cutting

Laser cutting has a wide array of applications: aerospace components requiring tight tolerances, automotive parts where strength and precision matter, medical devices such as stents and surgical tools, consumer electronics housings, and architectural features where aesthetics meet function. Its adaptability is one of its greatest strengths—but also one of the reasons why challenges emerge when trying to optimize across different industries.

Materials

- Reflective and Conductive Metals: Metals like aluminum, copper, and brass are both reflective and thermally conductive. These properties complicate laser cutting because energy is reflected toward the optics or dissipates too quickly, reducing efficiency. Fiber lasers have improved performance in these areas, but the problem of back-reflections damaging equipment persists.

- Coatings, Laminates, and Inconsistent Stock: Coated materials—galvanized steel, anodized aluminum, or adhesive-backed laminates—often absorb laser energy inconsistently. Layers may delaminate, edges may burn, and cut finishes can vary dramatically across the same sheet. Inconsistent stock thickness adds further variability, making precise process control difficult.

- Plastics and Fumes: Cutting plastics introduces unique challenges. While acrylic cuts cleanly with polished edges, materials like PVC release hydrochloric acid gas, which is both hazardous to health and corrosive to machine components. Polycarbonate may discolor or leave residue. Proper ventilation and careful material selection are mandatory to prevent health hazards and machine degradation.

Cut Quality and Consistency

- Edge Roughness, Striations, and Dross: High cut quality is a key selling point of laser cutting, but imperfections often arise. Striations—vertical lines on cut edges—are especially pronounced in thicker materials. Dross, or molten material that resolidifies on the underside, requires secondary operations to remove, reducing productivity.

- Kerf Width Variation and Taper: The kerf width depends on beam focus, power, and assist gas. Variations lead to dimensional inaccuracies. Taper, where the top of the cut is wider than the bottom, complicates assembly in precision applications.

- Small Holes, Corners, and Intricate Features: Laser cutting can produce intricate patterns, but small holes and sharp corners are difficult. Heat buildup may cause deformation, while machine motion limits often round corners or distort tiny features.

- Heat-Affected Zone (HAZ) and Metallurgical Effects: The heat input can alter material properties. Steel edges may harden, while aluminum alloys may lose strength due to microstructural changes. In high-performance industries, such as aerospace, controlling the HAZ is critical to part performance and safety.

Assist Gas

- Supply Stability: A consistent gas supply is essential. Pressure fluctuations lead to inconsistent cuts, increased dross, or incomplete penetration.

- Gas Choice Tradeoffs

- Oxygen: Enables fast cutting through exothermic reactions but leaves oxidized edges that may require additional cleaning or post-processing.

- Nitrogen: Produces bright, oxide-free edges, ideal for stainless steel, but requires high pressure and comes at a higher cost.

- Compressed Air: Offers a cost-effective compromise, though cut quality is often lower than with nitrogen or oxygen.

- Nozzle Technology: The nozzle controls the flow of assist gases and protects optics. Worn, misaligned, or contaminated nozzles cause turbulence, spatter, and inconsistent cut edges. Regular inspection and replacement are necessary to maintain high performance.

Optics, Alignment, and Back-Reflections

- Protective Windows and Lenses: Optics degrade over time due to spatter, fumes, and heat. Even small deposits on protective windows reduce beam quality, lowering efficiency and cut quality.

- Focus Drift and Thermal Lensing: As lenses absorb heat, their focal properties change—a phenomenon called thermal lensing. This causes the focal point to drift, which leads to variations in cut width and depth.

- Back-Reflections on Fiber Lasers: When cutting reflective materials, some energy reflects into the system. In fiber lasers, these reflections can travel back to the source, damaging sensitive components. Isolation devices and monitoring systems help mitigate the risk, but it remains a serious concern.

Motion System Limits

- Acceleration, Jerk, and Cornering: The precision of laser cutting depends heavily on the motion system. High accelerations and sharp cornering create vibrations and overshoot, resulting in edge defects or dimensional inaccuracies.

- Height Sensing and Standoff: Maintaining the correct distance between the nozzle and material is vital. Faulty height sensors cause poor focus, leading to incomplete cuts or collisions.

- Collision and Tip-Up: Thin sheets may warp or tip up during cutting, especially under thermal stress. If the sheet collides with the nozzle, it can damage the optics, nozzle, or part itself, causing costly downtime.

Fixturing, Sheet Handling, and Bed Maintenance

Proper fixturing ensures that sheets remain stable during cutting. Inadequate fixturing causes vibration, leading to poor cut quality. Handling large sheets manually is unsafe and inefficient, so many facilities rely on automation systems. Cutting beds accumulate slag and spatter over time, requiring routine cleaning to prevent secondary reflections, which degrade cut quality and pose fire risks.

Piercing Strategies and Thick-Plate Realities

- Time and Spatter: Piercing thick plates requires significant power and time. During this process, molten material and spatter can contaminate optics or leave defects. Multi-pulse piercing reduces damage but extends cycle time.

- Cut Speed vs. Cut Quality: In thick materials, cutting speed must be carefully balanced. Faster speeds reduce cycle time but often result in rough edges or incomplete penetration. Slower speeds improve quality but decrease productivity, affecting profitability.

Software

- Nesting and Material Utilization: Software plays a crucial role in optimizing sheet layouts. Effective nesting maximizes material usage and reduces waste, while poor nesting strategies result in higher scrap rates.

- Kerf Compensation and CAM Fidelity: Accurate kerf compensation ensures that final part dimensions match design specifications. Low-quality CAM software may introduce errors, leading to out-of-tolerance parts.

- Sequencing and Heat Maps: The order of cuts affects heat distribution. Cutting in a poorly planned sequence can warp sheets or distort dimensions. Advanced CAM software uses heat maps to optimize sequencing, reducing thermal distortion.

- Data and Traceability: Industries with strict quality requirements demand full traceability of materials and process parameters. Weak data management jeopardizes compliance, certification, and accountability.

Safety, Health, and Environment (SHE)

- Laser Class and Guarding: Industrial lasers fall under Class 4, the most hazardous category. Without proper guarding, they can cause permanent eye damage or severe burns. Interlock systems and safety protocols are essential.

- Fire Risk and Reactive Metals: Cutting reactive metals, such as magnesium or titanium, introduces significant fire risks. These require specialized fire suppression systems and vigilant operator monitoring.

- Fumes and Particulates: Laser cutting generates fine particulates and harmful fumes, especially when cutting plastics and coated metals. Without adequate ventilation and filtration, these pose serious health risks.

- Noise and Ergonomics: Assist gas systems, cutting operations, and sheet handling produce noise that can impact worker health. Manual handling of large sheets also creates ergonomic risks, leading to repetitive strain injuries.

Economics

- Upfront vs. Running Costs: Laser cutting machines represent a significant capital expense, often reaching hundreds of thousands of dollars. Running costs—gases, optics, maintenance, power consumption—add to the total cost of ownership. Facilities must carefully evaluate their production volumes and application needs to justify investment.

- Downtime and Maintenance: Unplanned downtime erodes profitability. Cleaning optics, replacing consumables, or realigning systems all take time and labor. Preventive maintenance reduces disruptions but requires careful planning and resources.

- Job Quoting Under Uncertainty: Quoting jobs accurately is difficult due to variable material behavior, consumable lifetimes, and cut times. Overquoting loses business, while underquoting erodes margins. This uncertainty challenges manufacturers, particularly in competitive markets.

Workforce, Training, and Knowledge Capture

Laser cutting demands skilled operators who understand not just the machines but also materials, optics, software, and safety. Training programs are resource-intensive, and experienced staff turnover can lead to knowledge gaps. Organizations must implement structured training, documentation, and digital knowledge capture to preserve expertise and reduce dependency on individuals.

Quality Assurance and Metrology

Meeting quality standards is essential in industries like aerospace and medical devices. Quality assurance ensures that parts meet dimensional tolerances, surface finish requirements, and metallurgical integrity. Advanced tools such as coordinate measuring machines (CMMs), optical scanners, and laser profilometers play a critical role. Beyond measurement, QA processes include statistical process control (SPC), documentation for traceability, and audits for compliance. Without rigorous QA, defective parts may escape detection, leading to costly recalls or safety hazards.

Summary

Laser cutting is a cornerstone of precision manufacturing, but it comes with a range of challenges that must be understood and managed. Materials behave unpredictably, optics degrade, gases fluctuate, and motion systems face mechanical limits. Safety and environmental issues add complexity, while high costs and workforce requirements impact economics. At the same time, stringent quality assurance demands require careful investment in metrology and compliance systems. None of these challenges diminishes the value of laser cutting—they simply underscore the importance of treating it as a sophisticated process that requires discipline, expertise, and continuous improvement. Companies that acknowledge and address these realities are best positioned to unlock the full potential of laser cutting technology while remaining competitive in demanding global markets.

Get Laser Cutting Solutions

While laser cutting presents undeniable challenges—ranging from reflective metals and thermal effects to safety, maintenance, and cost—these obstacles are far from insurmountable. The key lies in having the right technology partner and the right equipment. A professional manufacturer such as Maxcool CNC provides comprehensive solutions that address both the technical and operational hurdles of laser cutting.

Maxcool CNC’s intelligent laser equipment is designed with advanced optics, stable motion systems, and optimized software to maximize accuracy, efficiency, and consistency. Whether you are working with reflective alloys, thick plates, or delicate plastics, Maxcool CNC machines are engineered to minimize dross, reduce heat-affected zones, and deliver smooth edges across a wide variety of materials. Integrated safety features, reliable fume extraction, and robust fire prevention measures ensure that operations remain safe, compliant, and environmentally responsible.

Beyond the machine itself, Maxcool CNC supports customers with training, maintenance programs, and knowledge-sharing, helping manufacturers build skilled teams and sustain long-term productivity. This combination of technology and support transforms challenges into opportunities for efficiency, precision, and profitability.

For businesses looking to harness the full potential of laser cutting while managing its complexities, Maxcool CNC offers solutions that merge innovation with reliability—empowering manufacturers to stay competitive in demanding global markets.