Applications of Pulsed Laser Cleaning

Pulsed laser cleaning is emerging as a powerful alternative to conventional surface cleaning methods such as chemical solvents, abrasive blasting, or mechanical polishing. By delivering short, high-energy laser pulses to a material’s surface, this technique removes unwanted contaminants, oxides, coatings, or residues without damaging the underlying substrate. Its precision and controllability make it particularly attractive in industries where traditional cleaning methods fall short, either due to environmental concerns, safety risks, or the need for delicate handling.

Unlike chemical cleaning, pulsed laser cleaning does not generate hazardous waste, and unlike abrasive methods, it avoids physical wear on the substrate. The ability to selectively target contaminants with minimal thermal impact makes it suitable for sensitive applications ranging from aerospace components to cultural heritage preservation. Advances in laser technology have further expanded its applicability, enabling tailored cleaning processes for metals, polymers, ceramics, and even composite materials.

As industries face increasing pressure to adopt sustainable and efficient cleaning technologies, pulsed laser cleaning stands out for its versatility, environmental benefits, and high level of process control. This article explores the diverse applications of pulsed laser cleaning and highlights how it is reshaping surface treatment practices across multiple fields.

Table of Contents

Fundamentals of Pulsed Laser Cleaning

Pulsed laser cleaning is a surface treatment technique that uses short bursts of laser energy to remove unwanted materials such as rust, oxides, paints, or organic residues. Unlike continuous-wave lasers, which deliver a steady beam, pulsed lasers emit energy in rapid, concentrated bursts. This makes them especially effective for cleaning because each pulse delivers a high peak power in a very short time, ejecting contaminants without damaging the underlying surface. The technology has gained traction across industries because it offers precision, repeatability, and compatibility with sensitive materials while addressing environmental and safety concerns associated with traditional cleaning methods.

Principles of Operation

Pulsed laser cleaning relies on the interaction between short, high-energy laser pulses and contaminants on a material’s surface. When the laser beam strikes the target, the contaminant layer absorbs the energy more effectively than the underlying substrate due to differences in optical absorption. This rapid absorption generates localized heating, ablation, or even plasma formation, which lifts and ejects the unwanted material. Because the process operates on very short timescales (nanoseconds to femtoseconds), heat transfer to the bulk material is minimal, reducing the risk of substrate damage. By carefully controlling laser parameters such as pulse duration, fluence, wavelength, and repetition rate, operators can achieve precise cleaning tailored to specific materials and contaminants.

Key Characteristics

- Non-Contact Process: The laser beam cleans without mechanical force, avoiding abrasion or surface wear.

- High Selectivity: Differences in absorption allow contaminants to be removed while leaving the substrate intact.

- Controlled Energy Delivery: Adjustable laser settings enable optimization for metals, ceramics, polymers, or composites.

- Scalability: Systems can be applied to both small components and large industrial surfaces.

Advantages Over Conventional Cleaning

- Non-Contact Process: Unlike abrasive blasting or mechanical polishing, no physical tool touches the surface, eliminating mechanical stress or scratches.

- Selective Removal: Contaminants or coatings can be precisely removed without affecting the substrate, making it suitable for delicate surfaces such as aerospace alloys or historical artifacts.

- No Consumables: The process does not require chemicals, abrasives, or cleaning agents, reducing operating costs and logistics.

- Environmentally Friendly: By eliminating chemical solvents and minimizing waste, laser cleaning aligns with modern sustainability goals.

- Automation-Friendly: Laser cleaning can be easily integrated into robotic systems or automated production lines, improving consistency and throughput.

- Applicable to Sensitive Surfaces: Low thermal impact and fine control make it safe for high-value or fragile items, from semiconductor wafers to cultural heritage objects.

Pulsed laser cleaning combines advanced laser physics with practical surface treatment needs. Its principle of selective ablation allows precise contaminant removal with minimal substrate impact. The technique’s versatility, efficiency, and environmental advantages position it as a superior alternative to conventional cleaning methods. With growing demand for sustainable and automation-compatible processes, pulsed laser cleaning is becoming a cornerstone technology for industries that require precision, reliability, and care in surface preparation.

Automotive Industry Applications

The automotive sector is one of the largest adopters of pulsed laser cleaning technology, driven by its demand for efficiency, precision, and sustainability. Automakers are under constant pressure to reduce production costs while ensuring durability, safety, and compliance with increasingly strict environmental regulations. Traditional cleaning methods such as chemical solvents, sandblasting, or mechanical grinding often generate hazardous waste, cause substrate wear, or fail to meet quality standards. Pulsed laser cleaning provides a cleaner, faster, and more precise alternative. Its ability to selectively remove contaminants, oxides, paints, or residues without damaging the substrate makes it highly valuable in applications ranging from corrosion control to production line surface preparation.

Rust and Corrosion Removal

Rust and oxide buildup on automotive components, especially steel body panels and structural parts, can compromise safety and longevity. Pulsed laser cleaning effectively removes corrosion by targeting oxide layers with high absorption rates while preserving the underlying metal. Unlike mechanical grinding, which can thin or scratch surfaces, or chemical treatments, which produce toxic waste, laser cleaning achieves consistent results without surface degradation. This is particularly advantageous in restoring parts during remanufacturing or maintenance, where material preservation is critical.

Paint and Coating Removal

Automotive production frequently requires removal of paints, primers, or protective coatings, whether for rework, repair, or end-of-life recycling. Pulsed laser cleaning can strip coatings efficiently without harmful solvents or abrasives. By adjusting fluence and scanning parameters, operators can selectively remove multilayer coatings while leaving the substrate untouched. This capability supports sustainable practices such as recycling metal body parts, reducing chemical waste, and enabling localized rework on production lines.

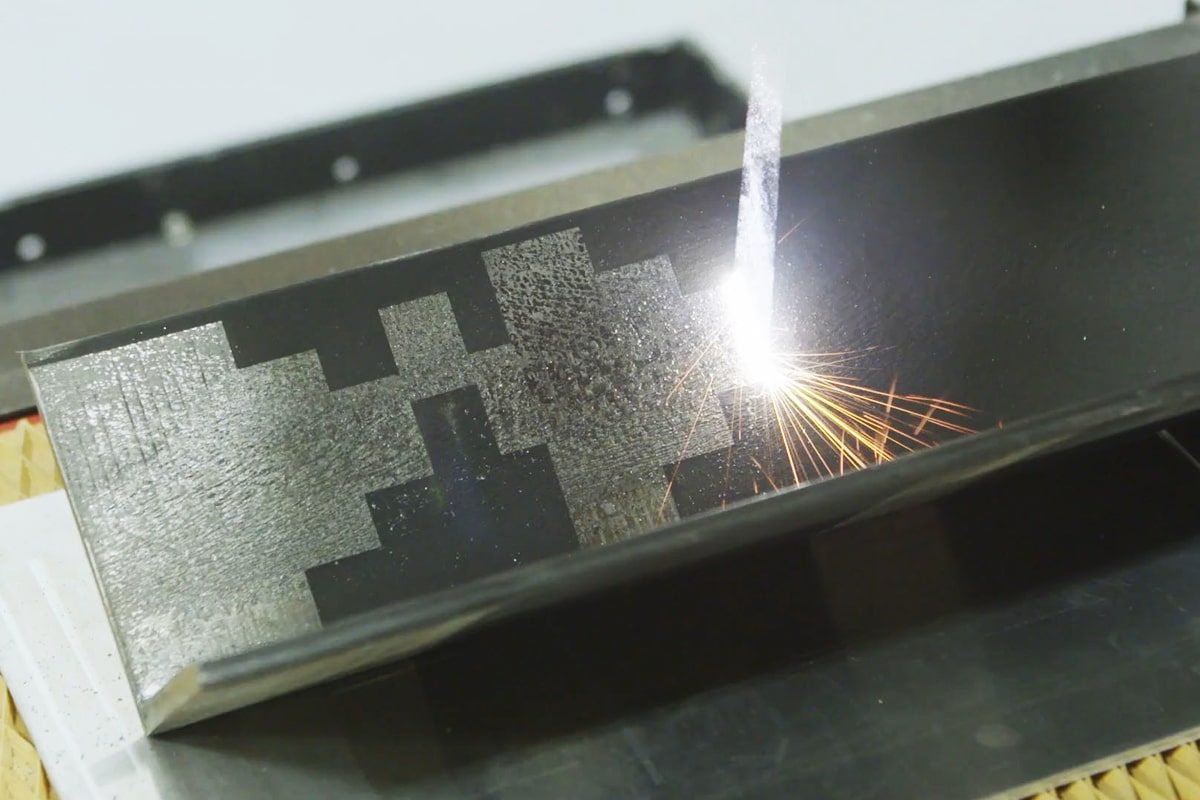

Pre-Welding Surface Preparation

Clean surfaces are essential for strong, defect-free welds in automotive assembly. Oil residues, oxides, or coatings at welding joints can cause porosity, weak bonds, or structural failures. Pulsed laser cleaning provides a non-contact, highly repeatable method for preparing weld surfaces by removing contaminants just before welding. Because the process leaves no chemical residues and causes no mechanical deformation, it improves weld quality and reduces rejection rates. This makes it especially valuable in robotic welding cells, where automated laser cleaning can be synchronized with welding operations for seamless integration.

Mold Cleaning in Tire Manufacturing

Tire production relies on molds that accumulate residues of rubber, carbon black, and release agents. Conventional cleaning methods often require disassembly, harsh chemicals, or abrasive blasting, leading to downtime and mold wear. Pulsed laser cleaning enables in-situ, non-contact removal of these deposits, restoring mold precision without damaging delicate mold textures or patterns. By extending mold life and reducing downtime, this approach improves production efficiency and product quality while minimizing environmental impact.

In the automotive industry, pulsed laser cleaning addresses multiple challenges where conventional methods fall short. From extending the life of rust-prone steel components and enabling sustainable paint removal to ensuring reliable weld joints and optimizing tire mold maintenance, the technology delivers measurable gains in efficiency, quality, and environmental performance. As automotive manufacturing becomes increasingly automated and sustainability-driven, pulsed laser cleaning is set to play a central role in modern production and maintenance practices.

Electronics and Semiconductor Industry

The electronics and semiconductor industry operates at the nanoscale, where even microscopic contaminants can compromise device performance, reliability, and yield. Traditional cleaning techniques—such as wet chemical processes, ultrasonic baths, or mechanical scrubbing—often introduce secondary residues, involve hazardous chemicals, or lack the precision needed for advanced microelectronics. Pulsed laser cleaning provides a non-contact, highly controlled solution capable of removing organic films, oxides, dust, and other contaminants without damaging delicate substrates. Its ability to deliver localized cleaning with minimal thermal effect makes it particularly suited for circuit boards, semiconductor wafers, and electrical connectors—three areas where cleanliness is directly tied to performance.

Precision Cleaning of Circuit Boards

Printed circuit boards (PCBs) are densely packed with micro-components and soldered joints, making them highly sensitive to contamination. Residues from soldering flux, conformal coatings, or environmental exposure can impair conductivity or cause corrosion. Pulsed laser cleaning can selectively remove these residues without harming copper traces, solder pads, or insulating materials. Its non-contact nature ensures no mechanical stress on fragile components, while precise targeting allows localized rework and repair—critical in high-value or mission-critical electronics.

Wafer Surface Preparation

In semiconductor fabrication, wafer surfaces must be pristine before lithography, deposition, or bonding steps. Even nanoscale particulates or oxide films can lead to defects that compromise yields. Pulsed laser cleaning offers sub-micron precision, removing organics, native oxides, or residual photoresist layers without scratching or etching the wafer. The short laser pulses minimize heat transfer, protecting delicate structures and thin films. Moreover, the process can be integrated in line with semiconductor production equipment, enabling automated, high-throughput wafer preparation that supports next-generation chip manufacturing.

Connector and Contact Cleaning

Electrical connectors and contacts are critical for ensuring reliable current flow in devices ranging from smartphones to aerospace electronics. Over time, these contacts accumulate oxides, dust, or thin films that increase electrical resistance and cause intermittent failures. Traditional cleaning methods can deform contact surfaces or leave residues that worsen performance. Pulsed laser cleaning removes oxidation and debris cleanly while preserving the geometry and conductivity of gold, silver, or copper contacts. This is especially important in high-frequency or high-reliability applications such as data centers, medical devices, and avionics.

In the electronics and semiconductor industry, pulsed laser cleaning addresses the growing demand for precision, reliability, and contamination-free surfaces. By enabling flux-free PCB rework, defect-free wafer preparation, and oxidation-free connectors, the technology ensures better product performance and higher manufacturing yields. Its non-contact, residue-free process not only improves quality but also aligns with industry trends toward automation and environmentally sustainable manufacturing. As device architectures shrink and performance requirements increase, pulsed laser cleaning is set to become a standard tool in microelectronics production and maintenance.

Cultural Heritage and Art Conservation

Cultural heritage conservation requires methods that are both effective and gentle, ensuring that valuable artifacts, artworks, and historical structures are preserved without risk of irreversible damage. Traditional cleaning methods—such as mechanical abrasion, chemical solvents, or abrasive blasting—can be invasive, difficult to control, and often irreversible. Pulsed laser cleaning has become a preferred tool in conservation because it offers unmatched precision, selectivity, and non-contact operation. By tuning parameters such as wavelength, fluence, and pulse duration, conservators can target unwanted deposits like dirt, biological growth, corrosion, or overpainting while leaving the original material intact. This technology not only preserves authenticity but also extends the lifespan of cultural artifacts with minimal intervention.

Cleaning of Stone Monuments

Outdoor stone monuments, statues, and architectural details accumulate layers of soot, biological growth, and environmental pollutants that obscure inscriptions and damage the surface. Pulsed laser cleaning provides a controlled way to remove these deposits without harming the delicate stone underneath. Unlike chemical cleaning, which may leave residues or alter the stone’s mineral composition, laser cleaning works selectively on surface contaminants. The technique has been widely used for iconic monuments such as cathedrals, sculptures, and archaeological remains, helping restore their appearance while preserving fine details.

Restoration of Metal Artifacts

Metal artifacts—bronze sculptures, silver ornaments, iron tools, or weaponry—are prone to corrosion and tarnishing over centuries. Traditional mechanical cleaning risks scratching or removing original patinas, while chemical methods may over-clean or cause long-term degradation. Pulsed laser cleaning can selectively remove corrosion layers while preserving the natural patina or gilding beneath, which is often critical for historical authenticity. For example, bronze statues can be restored by carefully eliminating green corrosion products without altering the underlying alloy, ensuring both aesthetic and structural preservation.

Document and Manuscript Cleaning

Historical manuscripts, paintings, and documents are highly sensitive to both chemicals and mechanical handling. Pulsed laser cleaning, particularly with low-energy ultraviolet or infrared pulses, can remove superficial deposits such as soot, mold, or aged varnish without damaging fragile inks, pigments, or fibers. Conservators can adjust laser settings to avoid heat buildup, ensuring that the substrate remains intact. This makes the method especially useful for restoring fire-damaged documents or cleaning centuries-old manuscripts where traditional methods would pose high risks.

Architectural Conservation

Historic buildings and interiors often feature intricate decorative elements, frescoes, or wall paintings that require delicate cleaning. Pulsed laser cleaning enables conservators to remove dirt, grime, and aged coatings layer by layer, allowing selective treatment of surfaces without compromising original paint layers or plaster. The method is especially valuable in restoring delicate interior artworks in cathedrals, palaces, and heritage sites where other cleaning techniques might prove too harsh. Its ability to be applied locally and precisely makes it indispensable for projects requiring both preservation and visual enhancement.

In cultural heritage and art conservation, pulsed laser cleaning has revolutionized the way conservators approach delicate restoration tasks. Whether reviving the details of stone monuments, protecting the authenticity of metal artifacts, restoring fragile manuscripts, or safeguarding historic architecture, the technique combines precision with safety. Its non-contact, selective removal process ensures that valuable cultural assets are cleaned without damage, supporting the long-term preservation of humanity’s shared heritage. As laser technology advances, its role in conservation will only expand, offering new possibilities for protecting and celebrating art and history.

Medical and Healthcare Applications

In the medical and healthcare sector, cleanliness and sterility are not optional—they are critical to patient safety and device performance. Contaminants such as biological residues, biofilms, and surface oxides can compromise the functionality of medical tools, introduce infection risks, or reduce the lifespan of sensitive equipment. Conventional cleaning methods like chemical disinfectants, ultrasonic baths, and mechanical polishing are widely used, but they often leave behind residues, degrade surface quality over time, or pose environmental and handling hazards. Pulsed laser cleaning offers a superior alternative: a non-contact, residue-free, and highly controllable process that removes contaminants without damaging sensitive surfaces. Its precision makes it especially suitable for applications ranging from surgical instruments to high-tech medical devices, where sterility and material integrity are paramount.

Surgical Instrument Cleaning

Surgical instruments must meet stringent sterility requirements, but repeated exposure to harsh chemical disinfectants or abrasive cleaning can cause wear, corrosion, or micro-damage. Pulsed laser cleaning removes blood residues, biofilms, and surface contaminants without causing mechanical abrasion or introducing chemical residues. Preserving the microstructure and sharpness of instruments such as scalpels, forceps, and surgical scissors extends their service life while ensuring they remain safe for repeated use.

Dental Applications

Dental tools and implants are highly prone to contamination due to direct exposure to biological materials. Traditional sterilization methods may not completely remove hardened deposits like tartar or biofilms from reusable tools. Pulsed laser cleaning provides precise removal of such contaminants without damaging metallic or ceramic surfaces. It also has potential applications in implantology, where surface preparation of dental implants is crucial for osseointegration. By removing surface oxides and creating micro-textures, laser cleaning enhances implant bonding with bone tissue.

Medical Device Manufacturing

The manufacturing of medical devices such as stents, pacemakers, orthopedic implants, and surgical robots requires ultra-clean surfaces for both performance and regulatory compliance. Contaminants like lubricants, oxides, and particulate matter left from machining or coating processes can compromise device functionality or biocompatibility. Pulsed laser cleaning ensures pristine surfaces by removing these residues without altering delicate geometries or coatings. The process can also be integrated into automated production lines, improving quality assurance while reducing reliance on chemical cleaning agents.

Endoscope and Optical Equipment Maintenance

Endoscopes, surgical microscopes, and other optical instruments are essential for minimally invasive procedures but are difficult to clean due to their complex geometries and sensitive optical elements. Conventional cleaning methods risk scratching lenses, degrading coatings, or leaving chemical residues that impair visibility. Pulsed laser cleaning can safely remove biofilms, residues, and deposits from glass and optical coatings without affecting transparency or alignment. This improves device longevity, reduces the risk of infection, and ensures high-quality imaging during medical procedures.

In healthcare, pulsed laser cleaning offers unmatched benefits where sterility, precision, and material preservation are critical. From extending the life of surgical instruments and ensuring sterile dental tools to enabling contamination-free medical device production and maintaining delicate optical equipment, the technology addresses gaps left by conventional cleaning methods. Its non-contact, residue-free, and automation-friendly nature makes it not only a safer choice for patients but also a more cost-effective and environmentally sustainable solution for hospitals and manufacturers alike. As demand for advanced medical devices and minimally invasive treatments grows, pulsed laser cleaning will continue to play an essential role in modern healthcare systems.

Energy and Power Generation

The energy and power generation sector relies on highly engineered components that must operate under demanding conditions of heat, pressure, and environmental exposure. Any contamination, corrosion, or surface defect can reduce efficiency, increase downtime, and compromise safety. Traditional cleaning techniques—such as abrasive blasting, chemical solvents, or manual polishing—are often difficult to apply in situ, generate hazardous waste, and may damage sensitive or high-value equipment. Pulsed laser cleaning provides a non-contact, precise, and environmentally friendly alternative. By selectively removing oxides, coatings, and deposits without harming the underlying material, it supports higher efficiency, longer component lifespans, and safer operation across the nuclear, renewable, and thermal power sectors.

Nuclear Industry

In nuclear power plants, surface contamination can include radioactive oxides, corrosion products, and other hazardous deposits on pipes, turbine parts, or reactor components. Traditional chemical cleaning produces secondary radioactive waste, complicating handling and disposal. Pulsed laser cleaning reduces this problem by minimizing waste generation and allowing highly localized decontamination. Its precision makes it ideal for cleaning delicate surfaces such as stainless steel and zirconium alloys used in reactors. Furthermore, the technology can be deployed remotely with robotic systems, enabling safe maintenance in high-radiation environments while protecting human workers.

Wind and Solar Energy

Renewable energy systems also benefit from pulsed laser cleaning. In wind power, turbine blades and gear components accumulate corrosion, grease, and coatings that reduce aerodynamic performance or mechanical efficiency. Laser cleaning can restore surfaces without introducing abrasives that would weaken blade composites. In solar energy, photovoltaic panels are highly sensitive to dirt, oxide films, and surface residues that reduce light absorption and efficiency. Pulsed lasers can clean panels with sub-micron precision, ensuring removal of deposits without scratching the glass or damaging anti-reflective coatings. The process supports longer panel lifetimes and consistent power output in large-scale solar farms.

Thermal Power Plants

In fossil-fuel and biomass power plants, boilers, turbines, and heat exchangers accumulate thick oxide scales, soot, and slag deposits during operation. These deposits reduce heat transfer efficiency, increase fuel consumption, and accelerate component wear. Conventional cleaning methods require shutdowns, aggressive blasting, or chemical treatments that degrade surfaces and extend downtime. Pulsed laser cleaning offers an efficient alternative by removing these deposits with high precision, often in situ, and without damaging structural alloys. This improves energy efficiency, reduces maintenance cycles, and extends equipment lifetimes, making it a cost-effective solution for thermal power operations.

Across the energy and power generation industry, pulsed laser cleaning addresses the dual challenges of maintaining efficiency and minimizing environmental impact. In nuclear plants, it enables safer decontamination with reduced radioactive waste. In renewable energy, it helps sustain the peak performance of wind turbines and solar panels. In thermal plants, it improves heat transfer efficiency and reduces downtime. By combining precision, safety, and environmental responsibility, pulsed laser cleaning is becoming an indispensable tool for modern energy systems, supporting both reliability and sustainability in global power generation.

Oil, Gas, and Petrochemical Industries

The oil, gas, and petrochemical sectors operate in some of the harshest industrial environments, where equipment is continuously exposed to corrosive chemicals, high pressures, temperature fluctuations, and marine or desert conditions. Surfaces in these industries often suffer from corrosion, scaling, coatings degradation, or contamination that can compromise safety, reduce efficiency, and shorten equipment lifespans. Traditional cleaning techniques—such as abrasive blasting, chemical treatments, or mechanical grinding—are widely used, but they generate significant waste, pose safety risks, and can damage critical infrastructure. Pulsed laser cleaning is emerging as a safer, cleaner, and more cost-effective alternative. By providing selective contaminant removal without harming substrates, it enables reliable maintenance of pipelines, offshore structures, and refinery equipment while reducing downtime and environmental impact.

Pipeline Maintenance

Pipelines are central to oil and gas transport but are prone to internal and external corrosion, scaling, and coating degradation. Conventional methods, such as sandblasting, often thin pipeline walls or leave residues that weaken protective coatings. Pulsed laser cleaning allows precise removal of rust, oxides, and scale without affecting the structural integrity of the pipeline steel. It is especially effective for weld joint preparation, ensuring that new welds achieve maximum strength and durability. The non-contact nature of laser cleaning also makes it suitable for robotic or automated pipeline maintenance systems, reducing the need for manual intervention in hazardous environments.

Offshore Structures

Offshore platforms and rigs are continuously exposed to saltwater, humidity, and marine growth, leading to corrosion and biofouling on structural steel, decks, and support systems. Traditional cleaning techniques often involve abrasive blasting, which creates large volumes of waste and requires containment measures to prevent environmental contamination. Pulsed laser cleaning offers a controlled, localized solution for removing corrosion, marine deposits, and failed coatings while minimizing secondary waste. Its portability and compatibility with robotic systems make it particularly advantageous for offshore applications, where worker safety and environmental compliance are top priorities.

Refinery Equipment

Refineries rely on heat exchangers, reactors, storage tanks, and pipelines that are vulnerable to fouling, corrosion, and deposits from hydrocarbon processing. Conventional cleaning methods can be labor-intensive, require chemical solvents, or necessitate extended shutdowns. Pulsed laser cleaning enables fast, in-situ cleaning of critical equipment surfaces, restoring efficiency without mechanical wear or chemical residues. It can also be applied to remove protective coatings or surface contaminants during scheduled maintenance or component replacement. By reducing downtime and avoiding harsh chemicals, laser cleaning improves refinery reliability and sustainability.

In the oil, gas, and petrochemical industries, pulsed laser cleaning delivers a safer, cleaner, and more precise alternative to conventional maintenance methods. For pipelines, it ensures structural integrity and weld quality; for offshore structures, it combats corrosion and biofouling while minimizing waste; and for refineries, it restores efficiency while reducing downtime and chemical use. With its non-contact, automation-friendly capabilities, pulsed laser cleaning not only enhances equipment reliability and longevity but also supports environmental stewardship and worker safety in one of the world’s most demanding industrial sectors.

Marine Industry

The marine industry operates in some of the most corrosive and biofouling-prone environments on earth. Constant exposure to saltwater, moisture, biological organisms, and harsh weather conditions accelerates corrosion, reduces efficiency, and increases fuel consumption. Traditional cleaning methods—such as abrasive blasting, chemical treatments, or mechanical scrubbing—are costly, labor-intensive, and often harmful to the environment due to secondary waste generation. Pulsed laser cleaning offers a modern, sustainable alternative that addresses these challenges. Its ability to selectively remove corrosion, biofouling, and coatings without damaging substrates makes it well-suited for ship hulls, propellers, and critical engine components. The technology improves operational efficiency, reduces downtime, and helps vessel operators meet strict environmental regulations.

Ship Hull Cleaning

Marine vessels accumulate biofouling such as algae, barnacles, and other marine growth on their hulls. This increases hydrodynamic drag, leading to higher fuel consumption and greenhouse gas emissions. Conventional hull cleaning methods involve abrasive blasting or toxic antifouling coatings, both of which create environmental hazards. Pulsed laser cleaning provides a non-contact, eco-friendly solution by removing biofouling and oxides with high precision. Unlike abrasive methods, it preserves the integrity of steel or aluminum hull surfaces and can be performed selectively on targeted areas, reducing maintenance downtime. Its application also supports the transition toward environmentally compliant hull maintenance by reducing the need for harmful chemical antifouling agents.

Propeller and Engine Component Maintenance

Propellers and underwater engine components are also prone to corrosion, fouling, and scale buildup, which reduce propulsion efficiency and increase wear. Traditional maintenance often requires dry-docking and intensive mechanical cleaning, which risks surface damage. Pulsed laser cleaning restores propeller surfaces by removing corrosion and marine deposits while maintaining the precise hydrodynamic shape of the blades. For engine components—such as pistons, cylinder heads, and heat exchangers—the technology removes oxides, carbon deposits, and fuel residues without altering the microstructure of high-performance alloys. This ensures longer service life, reduced fuel costs, and improved reliability of marine propulsion systems.

In the marine industry, pulsed laser cleaning addresses critical challenges of corrosion, biofouling, and efficiency loss. For ship hulls, it provides an environmentally friendly method of biofouling removal that reduces drag and fuel consumption. For propellers and engine components, it restores functionality without mechanical wear, extending component lifespans and lowering operational costs. By combining precision, environmental compliance, and compatibility with sensitive materials, pulsed laser cleaning is redefining maintenance practices in shipping and marine engineering, supporting both economic and sustainability goals.

Defense and Military Applications

The defense and military sector requires equipment that performs reliably in extreme and unpredictable conditions. Weapons, vehicles, and aerospace defense systems are often exposed to dust, sand, salt, moisture, and combustion residues that degrade performance and increase failure risks. Traditional cleaning methods—such as solvents, abrasive blasting, or manual scrubbing—can be time-consuming, hazardous to personnel, and damaging to sensitive components. Pulsed laser cleaning provides a non-contact, highly precise, and environmentally sustainable solution that enhances readiness, reduces downtime, and extends equipment lifespan. Its adaptability to automated or field-deployable systems makes it especially valuable for modern defense operations where speed, safety, and reliability are mission-critical.

Weapon Maintenance

Firearms, artillery, and other weapons accumulate carbon deposits, gunpowder residues, and oxide films during use. If not removed properly, these contaminants can impair accuracy, reliability, and firing safety. Traditional cleaning often requires strong solvents or abrasive methods that may corrode metal surfaces or wear down protective coatings. Pulsed laser cleaning offers a fast, residue-free alternative by selectively removing deposits without altering barrel rifling, surface coatings, or microstructures. The process can be applied to small arms, heavy weapons, and even missile systems, ensuring consistent performance while reducing reliance on hazardous cleaning chemicals.

Aerospace Defense Systems

Military aircraft, drones, and missile systems rely on high-performance components that must remain free of oxides, coatings, and debris. Surfaces exposed to high temperatures, such as turbine blades or exhaust systems, often accumulate oxide layers that compromise efficiency and durability. Pulsed laser cleaning can remove these layers with micron-level precision, preserving sensitive alloys like titanium and nickel superalloys. It is also used for surface preparation before bonding or coating, ensuring strong adhesion without introducing defects. For defense aerospace applications, the ability to clean without abrasive wear or chemical residues improves both mission reliability and component longevity.

Vehicle Maintenance

Military vehicles, including tanks, armored personnel carriers, and naval vessels, are often exposed to harsh environments that accelerate corrosion, rusting, and coating degradation. Conventional cleaning methods, such as sandblasting, can weaken structural components or create large amounts of hazardous waste. Pulsed laser cleaning restores vehicle surfaces by removing corrosion and failed coatings while preserving the integrity of steel or composite armor. It also supports welding and recoating processes by preparing surfaces cleanly and consistently. For naval defense vehicles, such as patrol boats or submarines, laser cleaning offers an effective way to combat biofouling and corrosion in marine environments.

In defense and military applications, pulsed laser cleaning enhances operational readiness by providing precise, non-contact, and residue-free cleaning solutions. From extending the reliability of weapons and improving aerospace system performance to maintaining ground and naval vehicles, the technology reduces downtime, enhances safety, and lowers maintenance costs. Its adaptability to automated, robotic, and portable systems makes it particularly suited for field use, aligning with modern military demands for rapid deployment and sustainable operations. As defense technologies advance, pulsed laser cleaning is poised to play an increasingly central role in ensuring mission effectiveness and equipment longevity.

Research and Laboratory Applications

In research and laboratory environments, precision and cleanliness are essential. Experiments often require contaminant-free surfaces, well-prepared samples, and highly reliable optical or microfabricated components. Even microscopic residues can compromise data accuracy, distort optical signals, or damage delicate instruments. Traditional cleaning methods—such as solvents, ultrasonic baths, or mechanical wiping—carry risks of leaving residues, introducing scratches, or altering surface chemistry. Pulsed laser cleaning provides a superior solution, offering selective contaminant removal with sub-micron precision and minimal thermal damage. Its non-contact nature makes it particularly valuable in laboratories where reproducibility, sterility, and equipment integrity are critical.

Sample Preparation

Accurate experimental results depend on properly prepared samples, whether for spectroscopy, electron microscopy, or surface analysis. Dust particles, organic films, or oxide layers can distort measurements or introduce artifacts. Pulsed laser cleaning allows researchers to selectively remove contaminants without altering the bulk material or introducing chemical residues. For sensitive materials—such as thin films, biomaterials, or nanostructures—the ability to fine-tune laser fluence and pulse duration ensures precise cleaning without compromising structural or chemical properties. This makes it particularly valuable in fields such as material science, life sciences, and nanotechnology research.

Cleaning Optical Components

Optical systems, including lenses, mirrors, and laser cavities, must remain free from dust, oxides, or thin films to maintain signal integrity and prevent laser-induced damage. Conventional cleaning methods, such as wiping with solvents, can scratch surfaces or leave streaks that degrade performance. Pulsed laser cleaning offers a non-contact method that restores optical clarity by removing contaminants while preserving coatings, reflectivity, and surface smoothness. This is particularly important in high-power laser laboratories, where even minor impurities can cause scattering, absorption, or catastrophic optical damage. By ensuring clean and defect-free optics, laser cleaning supports the longevity and reliability of advanced research setups.

Microfabrication

Microfabrication processes used in electronics, photonics, and MEMS (microelectromechanical systems) demand ultra-clean surfaces at every stage of production. Residues from photolithography, deposition, or etching can compromise device performance and yields. Pulsed laser cleaning provides localized, precise removal of these residues without damaging delicate microstructures. It can also induce beneficial micro-textures on surfaces to enhance adhesion for coatings or bonding. In research laboratories developing next-generation devices, laser cleaning ensures process reliability and reproducibility, enabling rapid prototyping and high-quality experimental results.

In research and laboratory applications, pulsed laser cleaning provides unmatched precision and control, supporting the highest standards of cleanliness and reproducibility. From preparing pristine samples and maintaining high-performance optical components to enabling defect-free microfabrication, the technology enhances both experimental accuracy and equipment longevity. Its non-contact, residue-free operation reduces risks associated with traditional cleaning methods, making it an indispensable tool in modern scientific research. As laboratories push the boundaries of nanotechnology, optics, and materials science, pulsed laser cleaning will continue to play a key role in enabling breakthroughs and ensuring reliable results.

Summary

Pulsed laser cleaning has established itself as a transformative technology across a wide range of industries by addressing limitations of traditional cleaning methods. Its unique advantages—non-contact operation, selective contaminant removal, absence of consumables, and environmentally friendly performance—make it a powerful alternative to chemical, abrasive, and mechanical approaches. From restoring corroded automotive parts and ensuring defect-free aerospace components to cleaning sensitive semiconductor wafers and preserving centuries-old cultural artifacts, the technology demonstrates exceptional versatility.

In healthcare, it enhances sterility and device performance, while in the energy sector, it supports efficiency and safety in nuclear, renewable, and thermal power systems. The oil, gas, and marine industries benefit from reduced corrosion and biofouling, while defense applications leverage its precision for maintaining weapons, vehicles, and aerospace systems. Research laboratories also depend on pulsed laser cleaning to prepare pristine samples, maintain optical clarity, and enable advanced microfabrication.

What unites these diverse applications is the ability of pulsed laser cleaning to balance precision with sustainability, performance with safety, and efficiency with cost-effectiveness. As industries increasingly move toward automation, stricter environmental regulations, and higher performance standards, pulsed laser cleaning is poised to become not just an alternative but a standard tool for modern maintenance, manufacturing, and preservation.

Get Laser Cleaning Solutions

Pulsed laser cleaning is no longer a niche technology—it is becoming an essential tool for industries that demand precision, efficiency, and environmental responsibility. Whether you operate in automotive, aerospace, energy, healthcare, or cultural heritage conservation, the ability to remove rust, oxides, coatings, or contaminants without damaging the underlying material can significantly reduce downtime, extend equipment life, and improve product quality. As industries transition toward greener and more automated manufacturing processes, investing in laser cleaning solutions is both a strategic and sustainable choice.

At Maxcool CNC, we specialize in designing and manufacturing intelligent laser cleaning systems tailored to meet diverse industrial needs. Our pulsed laser cleaning solutions deliver consistent results, combining high energy efficiency with user-friendly automation features. Whether you require compact, portable systems for field applications or high-power, fully automated units for integration into production lines, Maxcool CNC offers solutions engineered for performance, reliability, and long-term cost savings.

By choosing Maxcool CNC, you gain more than a machine—you gain a partner committed to innovation and precision. Contact us today to explore how our laser cleaning systems can transform your maintenance and production processes, helping your business achieve higher efficiency and stay ahead in a competitive marketplace.