Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

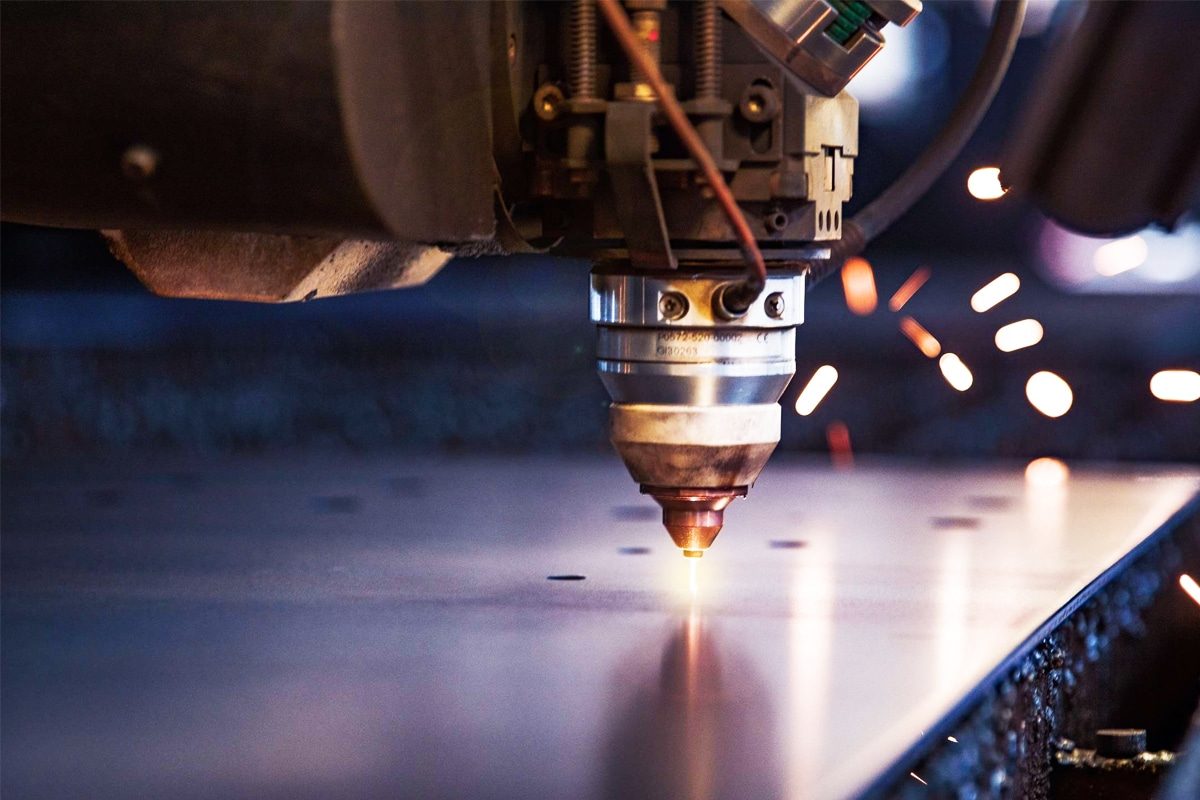

Fiber laser cutting has become one of the most important manufacturing technologies in modern metal fabrication, valued for its high speed, exceptional precision, energy efficiency, and ability to process a wide range of materials. As industries such as automotive, aerospace, construction, and custom metalworking continue to push for higher productivity and tighter tolerances, fiber laser systems have rapidly replaced traditional CO₂ and mechanical cutting methods. However, despite their advanced capabilities, fiber laser cutting machines are not immune to challenges. Daily operation often brings issues related to cutting quality, machine stability, consumable wear, parameter optimization, and the interaction between materials and laser energy. Left unresolved, these problems can lead to production downtime, inconsistent edge quality, increased operational costs, and reduced machine lifespan.

Understanding these challenges—and knowing how to diagnose and correct them—is essential for manufacturers who want to maximize the performance and ROI of their fiber laser cutting equipment. This article provides a comprehensive overview of the most common problems encountered during fiber laser cutting, explains their underlying causes, and offers practical, field-tested solutions to ensure stable operation, high-quality cuts, and long-term reliability. Whether you are a machine operator, production manager, or equipment purchaser, this guide will help you optimize your cutting process and overcome the real-world obstacles of fiber laser machining.

Table of Contents

Material-Related Challenges

The performance of fiber laser cutting is deeply influenced by the physical characteristics of the material being processed. Even high-power, high-stability fiber lasers can experience inconsistent cutting quality when material properties such as reflectivity, thermal conductivity, overall flatness, and thickness fall outside optimal ranges. These material-related variables affect how the laser beam interacts with the workpiece, how heat is absorbed and dissipated, and how molten metal is expelled from the kerf. If not properly addressed, they can lead to incomplete cuts, burrs, excessive dross, unstable piercing, or even damage to optical components. Understanding these challenges—and applying targeted process adjustments—is essential to ensuring reliable, repeatable cutting performance across diverse metals.

Reflectivity and Conductivity

Causes

Highly reflective metals such as aluminum, brass, copper, and gold have surfaces that initially reflect a significant portion of the laser energy rather than absorbing it. At the same time, their high thermal conductivity draws heat away from the cutting zone, preventing the temperature from reaching the melting threshold. These factors make it difficult for the laser to establish a stable keyhole, resulting in inconsistent kerf formation, slow cutting speeds, rough edges, or failed piercings. Excessive reflected energy can also travel back through the optical system, posing a risk to the laser source and protective optics.

Solutions

Improving absorption and stabilizing heat input is key. Using a fiber laser with higher peak power or shorter wavelengths helps reduce reflectivity and improve initial coupling. Applying specialized coatings, surface roughening, or laser-etching the pierce point can create a more absorptive surface. Optimizing parameters such as higher power density, slower cutting speeds, tighter focus spot, and longer piercing times allows the heat to accumulate more effectively. Using appropriate assist gases—such as nitrogen for clean edges or oxygen for improved absorption—also enhances cutting performance. Maintaining proper protective windows and back-reflection detectors is essential to protect the laser source during the processing of reflective materials.

Material Warpage and Deformation

Causes

Thin sheet metals, heat-sensitive alloys, and materials with internal stress may warp or distort when exposed to intense localized heat. During laser cutting, thermal gradients can cause the material to bend, twist, or lift from the cutting table. Warpage alters the focal distance, disrupts gas flow, and increases the likelihood of collision with the cutting head. Elevated heat input may also cause microstructural changes, leading to edge hardening or discoloration.

Solutions

Controlling heat input is crucial for minimizing distortion. Operators can reduce laser power during contour cutting, increase cutting speed, and use pulsed or high-frequency cutting strategies to limit heat accumulation. Proper fixturing—such as clamps, magnets, or weight systems—helps keep the material flat, while using a vacuum or zoned suction platform ensures stable sheet support. Selecting optimized cutting paths, minimizing long continuous cuts, or sequencing cuts to balance heat distribution can also prevent deformation. Pre-processed materials with stress-relief treatments or improved flatness specifications provide more predictable cutting behavior.

Material Thickness

Causes

Very thin materials are susceptible to excessive melting, burn-through, or vibration during high-speed cutting. Conversely, thick materials require much higher power, longer piercing times, and optimal beam focus to achieve full penetration. Inadequate power density, misaligned focus position, or inappropriate gas pressure can lead to incomplete cuts, large burrs, or tapering of the kerf. Thicker plates also dissipate heat more slowly, which increases the risk of slag accumulation or excessive heat-affected zones.

Solutions

For thin sheets, reducing laser power, increasing speed, and selecting a smaller focus spot produce clean, narrow kerfs without overheating. Using nitrogen as an assist gas prevents oxidation and helps maintain edge quality. When cutting a thick plate, operators should use a higher power output, an enlarged focus diameter for deeper penetration, and elevated oxygen or nitrogen pressure to efficiently remove molten metal. Adjusting the focal position slightly below the material surface helps maintain kerf straightness in thick cutting. Ensuring stable piercing—possibly using piercing delay, multi-stage piercing, or advanced piercing strategies—greatly improves reliability in heavy-plate processing.

Material properties are among the most influential factors in fiber laser cutting quality. Reflective and highly conductive metals require enhanced energy absorption strategies and protective measures to prevent back-reflection. Warpage and deformation must be controlled through careful heat management, optimized cutting strategies, and stable material support. Variations in material thickness demand tailored power, speed, focus, and gas-pressure adjustments to achieve consistent penetration and minimal burrs. By understanding how different materials interact with the laser beam—and by applying precise parameter optimizations—operators can maintain high-quality, predictable cutting performance across the full range of metals processed on fiber laser cutting systems.

Edge Quality and Knife Width

Edge quality is one of the most visible indicators of fiber laser cutting performance. Manufacturers typically expect smooth, clean edges with minimal burr formation and consistent kerf (knife width) across the entire cutting path. However, achieving perfect edge quality requires precise coordination of laser power, focus position, assist gas behavior, cutting speed, and material characteristics. Any deviation in these parameters can directly impact molten metal removal, heat distribution, and kerf geometry, resulting in rough edges, excessive dross, or irregular knife width. Because edge quality has a direct influence on downstream operations such as bending, welding, painting, and surface finishing, addressing these issues is essential to maintaining high production efficiency and reducing rework.

Rough Edges and Burrs

Causes

Rough edges or burr formation typically result from incomplete expulsion of molten metal from the kerf. This is often caused by insufficient assist gas pressure, incorrect gas type, low power density, or an unstable focus position that prevents proper melting and airflow. Cutting too slowly can allow excessive heat to accumulate, thickening the melt layer and causing slag adhesion. Cutting too quickly, on the other hand, may prevent full penetration, leaving attached micro-burrs. Contamination of the nozzle, worn ceramic rings, and degraded protective windows reduce beam quality and gas flow symmetry, also contributing to edge roughness. Material-related factors such as mill scale, coatings, rust, or inconsistent plate composition can introduce uneven absorption and unpredictable melting behavior.

Solutions

Improving burr control requires optimizing both beam characteristics and molten metal evacuation. Operators should ensure that the focus position is properly calibrated for the material and thickness, often slightly below the surface for carbon steel and near the middle of the plate for stainless steel. Increasing assist gas pressure or switching to nitrogen can dramatically improve melt removal, while oxygen cutting may require more precise control of power to prevent excessive oxidation. Cutting speed should be adjusted to maintain a stable cutting front—too slow causes overheating, while too fast leads to incomplete cuts. Regularly inspecting and replacing nozzles, maintaining coaxial alignment, and keeping the protective lens clean ensures consistent beam quality and airflow. Pre-cleaning materials to remove rust, oil, or coatings also help achieve smoother edges and reduce slag.

Knife Width Variation

Causes

Knife width variation—changes in the kerf size along the cut—usually stems from instability in the laser beam, fluctuations in focus, or inconsistency in gas flow. A worn nozzle, damaged tip, or poor nozzle centering disrupts gas symmetry, causing the kerf to widen or narrow unpredictably. Thermal drift in the cutting head or material deformation during processing can shift the effective focal point, altering the beam’s energy density. Incorrect selection of focus spot size or mode configuration also affects kerf geometry. Machine vibration, uneven material flatness, and inconsistent sheet thickness can further contribute to changes in knife width. In thicker plates, the kerf may widen near the top surface and taper toward the bottom due to insufficient penetration power.

Solutions

Maintaining consistent kerf width requires controlling beam quality, focus stability, and gas flow dynamics. Operators should choose an appropriate lens and focus spot based on material thickness and ensure that the focal point is precisely positioned before cutting. Using autofocus systems or checking calibration regularly prevents drift during long cutting cycles. Replacing worn nozzles and ensuring coaxial gas alignment maintains pressure symmetry, which is critical for stable kerf geometry. Increasing laser power or adjusting frequency can help achieve deep, uniform penetration in thick materials. Keeping the material flat—using suction, clamps, or support pins—prevents variations in focal distance that could affect kerf width. When cutting reflective or highly conductive materials, adjusting power density and gas type helps maintain a consistent melt pool and prevents kerf fluctuation.

Edge quality and knife width are critical performance indicators in fiber laser cutting, directly influencing part fit, weld integrity, and downstream finishing. Rough edges and burrs usually arise from improper heat control, insufficient gas flow, or instability in the laser beam or focus position. These can be mitigated through precise parameter adjustment, high-quality optics maintenance, and improved material preparation. Knife width variation is often linked to focus drift, gas asymmetry, or inconsistent material conditions; maintaining nozzle integrity, ensuring flat sheet support, and optimizing laser power and focus configuration are key solutions. By controlling these factors, manufacturers can consistently achieve clean, accurate cuts with predictable kerf geometry, improving both product quality and operational efficiency.

Process-Related Challenges

Even with a stable laser source and high-quality material, process-related factors can significantly influence the consistency of fiber laser cutting. Among these, slag accumulation is one of the most frequent and disruptive issues encountered in daily production. Slag—sometimes referred to as dross or spatter—forms when molten material fails to exit the kerf cleanly and re-solidifies on the underside of the workpiece. Excessive slag not only affects the aesthetic quality of parts but can also interfere with bending, welding, and painting operations, ultimately increasing rework time and production costs. Because slag formation is directly tied to how efficiently the cutting process removes molten metal from the kerf, understanding the thermal dynamics, gas behavior, and process parameters is essential to achieving clean, stable cuts across different metals and thicknesses.

Slag Accumulation

Causes

Slag buildup typically results from insufficient evacuation of molten metal during cutting. One common cause is inadequate assist gas pressure or an incorrectly chosen gas type. When gas velocity is too low or gas flow is asymmetrical due to nozzle wear or contamination, molten metal is unable to escape and solidifies on the underside of the sheet. Another major factor is improper cutting speed. Cutting too slowly allows heat to accumulate excessively, causing the melt pool to become thick and sticky. Cutting too quickly can result in incomplete kerf penetration, leaving semi-molten metal trapped along the cut edge. Incorrect focus position—either too high or too low—reduces energy density and produces unstable kerf geometry that complicates melt removal. Material thickness, coatings, mill scale, and quality inconsistencies can also influence how the melt behaves during the cutting process.

Solutions

To reduce slag accumulation, operators must optimize both thermal input and melt expulsion. Increasing assist gas pressure or switching to nitrogen for stainless steel and aluminum can greatly improve molten metal removal. For carbon steel, adjusting oxygen power settings or using oxygen–nitrogen hybrid processes may help achieve cleaner cuts. Ensuring that the nozzle is clean, undamaged, and properly centered keeps gas flow symmetrical and maintains a strong downward jet. Adjusting cutting speeds is equally crucial: increasing speed prevents overheating on thick plates, while reducing speed ensures full penetration on thicker or highly conductive materials. Correcting focus position—typically slightly below the surface for carbon steel and at mid-thickness for stainless steel—maximizes energy density and stabilizes keyhole formation. Pre-cleaning materials to remove rust, oil, or scale ensure consistent absorption, reducing the risk of uneven melting and slag buildup.

Process-related challenges, such as slag accumulation, can significantly impact overall cutting quality and operational efficiency in fiber laser machining. Slag is primarily caused by poor removal of molten metal, often linked to inadequate gas pressure, unstable beam focus, incorrect cutting speed, or inconsistencies in material surface conditions. Solving these issues requires balancing thermal input with efficient melt evacuation through optimized gas selection, proper nozzle maintenance, accurate focus calibration, and appropriate speed adjustments. By refining these parameters and ensuring stable process control, manufacturers can achieve cleaner cuts, reduce rework, and enhance the productivity and reliability of their fiber laser cutting operations.

Piercing and Startup Issues

Piercing and initial cut startup are critical phases in the fiber laser cutting process. Before the machine transitions into continuous cutting, the laser must successfully create an initial hole (piercing) and establish a stable kerf. Any instability during these early moments can compromise edge quality, increase slag, cause cut interruptions, or even damage the nozzle and optics. Problems such as delayed piercing, failed holes, or unstable startup often stem from incorrect parameters, inadequate gas flow, or material-specific conditions. Because these issues influence the entire cutting sequence, optimizing the piercing and startup workflow is essential for achieving consistent, high-efficiency production—especially when processing thick plates, reflective metals, or materials with coatings.

Piercing Delay and Failure

Causes

Piercing problems generally occur when the laser fails to achieve full penetration through the material within the programmed time. Several factors can contribute to this. If laser power is too low or the focus is positioned incorrectly, the laser may not generate sufficient energy density to melt through the material. Thick plates, highly reflective surfaces, and heat-conductive metals such as aluminum or copper make the piercing process more challenging, requiring higher initial energy. Inadequate assist gas pressure or incorrect gas selection also leads to insufficient molten metal removal, which prolongs piercing time or causes complete failure. Additionally, dirty protective lenses, worn ceramic rings, or misaligned nozzles can degrade beam quality, resulting in an unstable piercing hole or incomplete penetration. Material impurities, coatings, rust, or mill scale can further obstruct proper absorption and hinder piercing performance.

Solutions

Improving piercing reliability requires careful tuning of laser and gas parameters. Increasing peak power, using a smaller focus spot, or lowering the focus below the material surface can provide the concentrated energy needed for rapid penetration. Multi-stage piercing programs—such as pre-piercing with pulsed mode followed by continuous-wave piercing—help stabilize the melt pool, especially on thick or reflective materials. Raising assist gas pressure or switching to oxygen for carbon steel enhances molten metal expulsion, shortening piercing time. Maintaining clean optics and ensuring that nozzles are centered and undamaged prevents beam distortion. Pre-cleaning materials, removing coatings, or using laser etching to break surface reflectivity can further improve initial absorption and reduce piercing delays.

Unstable Startup

Causes

An unstable startup occurs when the cut fails to form a stable kerf immediately after piercing. This is often due to improper transition parameters between piercing and cutting modes. Excessive power during startup can overheat the area, causing spatter or blowouts, while insufficient power results in incomplete kerf formation. Incorrect focus position—especially if the piercing focus differs significantly from the cutting focus—can cause a temporary mismatch in energy density. Low or fluctuating gas pressure disrupts melt removal, leading to dross accumulation at the start of the cut. Nozzle contamination, asymmetrical gas flow, and debris from the initial pierce can also interfere with kerf stabilization. In thicker materials, residual molten metal from the piercing hole may obstruct the path of the cutting beam, causing momentary instability.

Solutions

Achieving a stable startup requires synchronizing power, focus, and gas settings immediately after piercing. Using a controlled ramp-down of piercing power—followed by a ramp-up of cutting parameters—creates a smooth transition into stable kerf formation. Ensuring that the focus position shifts precisely to the optimized cutting focal point prevents energy mismatch. Increasing gas pressure momentarily during startup can help clear trapped molten metal from the piercing hole. Regular calibration of nozzle alignment and cleaning of protective windows maintains consistent beam delivery. For thick plates, employing techniques such as “lead-in cuts,” “micro-joints,” or “pre-evacuation pulses” can stabilize the initial cutting segment and prevent slag accumulation. Selecting appropriate lead-in geometry also reduces stress concentration at the startup point.

Piercing and startup are among the most sensitive stages in the fiber laser cutting process. Delayed or failed piercing typically results from insufficient energy density, poor gas flow, dirty optics, or challenging material characteristics. These issues can be resolved by adjusting laser power, optimizing focus position, increasing assist gas pressure, and maintaining clean, properly aligned cutting components. An unstable startup often arises from improper parameter transitions, gas flow inconsistency, or leftover melt from piercing. Carefully managing power ramping, gas dynamics, and focus shift ensures that the kerf forms quickly and cleanly. By optimizing these initial steps, manufacturers can achieve more reliable cutting, reduce scrap, and improve overall process efficiency.

Machine-Related Challenges

While material conditions and process settings significantly influence fiber laser cutting performance, machine-related factors play an equally critical role in maintaining stable, high-quality operation. Fiber laser cutting systems rely on a complex combination of optical transmission components, precision mechanical assemblies, motion control systems, and environmental protections. Over time, these elements can degrade, drift out of calibration, or accumulate contamination—creating challenges that directly affect beam delivery, cutting accuracy, and operational efficiency. Issues such as beam transmission instability or mechanical wear often develop gradually and may go unnoticed until they cause visible cutting defects, higher rejection rates, or unexpected downtime. Understanding these machine-related challenges and applying proactive maintenance strategies is essential for sustaining long-term performance and minimizing disruptions.

Beam Transmission System Issues

Causes

Beam transmission problems arise when the optical path from the laser source to the cutting head becomes unstable or obstructed. In fiber laser cutting systems, this typically involves the delivery fiber, collimating lens, focusing lens, protective window, and nozzle. Contamination from dust, metal vapor, or spatter can accumulate on the protective window and lenses, reducing beam quality and causing energy loss or beam distortion. Misalignment in the optics—caused by mechanical shock, thermal expansion, or improper installation—alters the focal position and reduces power density at the cutting point. Damage to the delivery fiber, such as micro-bending or back-reflection exposure, can degrade transmission efficiency. Additionally, poor cooling system performance can cause thermal drift, leading to fluctuation in beam shape during extended cutting cycles.

Solutions

Maintaining a stable beam transmission system requires rigorous cleaning, inspection, and alignment control. Operators should regularly replace protective windows and inspect lenses for burn marks, scratches, discoloration, or debris. Ensuring proper nozzle centering maintains symmetric gas flow and protects the optical path from contamination. Implementing automated back-reflection monitoring can detect dangerous energy return from reflective materials and prevent damage to the laser source or fiber. Proper cooling system maintenance—including cleaning filters, checking coolant levels, and ensuring stable water temperature—helps minimize thermal drift. When alignment issues arise, recalibrating the optical path or using software-based autofocus systems ensures consistent focusing performance. Training operators in correct startup, cleaning, and nozzle-changing procedures also reduces the risk of accidental damage to the optical components.

Mechanical Wear

Causes

Mechanical wear develops naturally throughout the laser cutting machine’s motion system. Key components such as linear guide rails, rack-and-pinion assemblies, ball screws, bearings, and drive belts undergo continuous stress during high-speed positioning and acceleration. Over time, friction, vibration, and environmental contaminants can degrade these parts. Dust, metal debris, and inadequate lubrication can accelerate wear, leading to backlash, uneven movement, or reduced positional accuracy. Gear wear or loose couplings may cause jerky motion, poor interpolation, or dimensional errors in cut parts. Additionally, the cutting table slats gradually deform or accumulate slag, affecting material support and altering focal distance during cutting. Machines operating in harsh environments or with heavy production loads experience significantly faster mechanical degradation.

Solutions

Minimizing mechanical wear requires a structured maintenance program and timely replacement of critical components. Regular lubrication of guide rails, gears, and bearings reduces friction and prolongs service life. Cleaning the machine interior and cutting table prevents slag buildup that could interfere with material flatness or obstruct motion systems. Periodic calibration of the motion control system—such as checking backlash, inspecting rail smoothness, and verifying encoder accuracy—ensures precise positioning and smooth motion. Worn table slats should be replaced to maintain proper workpiece support and consistent focus height. Monitoring drive motor and gearbox temperatures helps detect early signs of mechanical stress. For high-duty environments, implementing vibration-damping measures or upgrading to higher-grade mechanical components can further improve stability. Training operators to handle materials gently and avoid collisions with the cutting head also reduces premature wear.

Machine-related challenges can gradually degrade cutting quality and process stability in fiber laser cutting systems. Beam transmission issues typically arise from contaminated optics, misalignment, or thermal drift, all of which reduce energy density and impair cutting performance. These can be mitigated through systematic cleaning, proper cooling, optical alignment control, and timely replacement of protective components. Mechanical wear—affecting guide rails, motors, gears, and table slats—can cause motion inaccuracies, poor edge quality, and inconsistent focus. Regular lubrication, vibration control, motion calibration, and component replacement are essential for preventing production disruptions. By proactively managing both optical and mechanical systems, manufacturers can ensure long-term reliability, reduced downtime, and consistently high cutting precision.

Taper and Angular Deviation

Taper and angular deviation are common geometric issues in fiber laser cutting that can directly affect dimensional accuracy, assembly fit, and downstream processes such as welding or precision machining. These imperfections occur when the cutting kerf is not perfectly perpendicular to the material surface, resulting in angled edges, uneven kerf widths, or inconsistent part tolerances. While advanced fiber lasers and cutting heads are designed to provide highly vertical cuts, several factors—including beam focusing behavior, material thickness, thermal conditions, and mechanical stability—can influence how the beam interacts with the workpiece. Understanding why taper and angular deviation occur and how to correct them is crucial for producing high-precision parts, especially in industries that demand strict geometric tolerances.

Taper

Causes

Taper appears when the kerf width changes between the top and bottom of the cut, forming a V-shaped or inverted V-shaped geometry. In thick plates, insufficient power density may cause the upper section to melt cleanly while the lower part receives less energy, resulting in a wider kerf at the top and a narrower one at the bottom. Incorrect focus position, such as focusing too far above or below the optimal zone, reduces effective penetration and skews the energy distribution within the material. Inconsistent or low gas pressure can hinder efficient removal of molten metal at the bottom of the kerf, increasing taper severity. Beam quality degradation, nozzle misalignment, thermal distortion, and machine vibration can all contribute to uneven kerf geometry. Materials with high reflectivity or thermal conductivity also make consistent deep penetration more difficult, increasing the likelihood of taper.

Solutions

Reducing taper requires stabilizing the beam’s penetration characteristics and ensuring uniform energy delivery throughout the material thickness. Adjusting the focal position—often slightly below the mid-thickness for heavy plates—helps maintain a consistent melt profile. Using a larger focus diameter or optimizing beam mode (such as switching between single-mode and multi-mode configurations) can improve bottom energy density. Increasing laser power, slowing cutting speed, or enhancing assist gas pressure ensures sufficient melt removal and cleaner lower kerf edges. Ensuring nozzle coaxiality and replacing worn nozzles maintains stable gas flow and symmetrical kerf formation. For highly reflective materials, advanced strategies such as ramp-up power, pre-heating, or specialized pierce programs help establish stable penetration that minimizes taper.

Angular Deviation

Causes

Angular deviation occurs when the cut edge is not perpendicular to the workpiece, creating a slanted or uneven edge that affects dimensional accuracy. This issue is often caused by beam tilt, misalignment in the cutting head, or mechanical instability in the motion system. If the nozzle is not perfectly centered or if the cutting head is not perpendicular to the table surface, the beam may strike the material at an angle. Wear in guide rails, backlash in drive systems, or uneven material support can also introduce angular error during movement. Thermal deformation during cutting—especially in large or thin sheets—can cause the material to lift, altering the relative angle between the beam and the surface. Variations in sheet thickness or material flatness further contribute to angular deviation by affecting focal distance.

Solutions

Correcting angular deviation begins with verifying the mechanical and optical alignment of the cutting head. Checking head perpendicularity and adjusting calibration ensures that the beam enters the material vertically. Ensuring nozzle centering and symmetrical gas flow minimizes directional bias in the kerf. Calibrating guide rails, verifying encoder accuracy, and tightening drive components prevent motion-induced angular shifts. Using suction systems, clamps, or improved material supports helps maintain flatness and prevents sheet lifting during cutting. Adjusting cutting paths, sequencing, or heat distribution strategies mitigates thermal distortion that could lead to angular error. For demanding precision work, routine alignment checks and periodic machine geometry inspections are essential to maintaining consistently accurate cuts.

Taper and angular deviation are geometric defects that reduce cutting accuracy and can compromise assembly quality. Taper typically results from insufficient penetration power, improper focus position, weak gas flow, or beam instability. These issues can be resolved by optimizing focus position, adjusting laser power and cutting speed, enhancing assist gas performance, and maintaining clean, properly aligned optical components. Angular deviation often stems from mechanical misalignment, nozzle or head tilt, uneven material support, or motion system wear. Ensuring head perpendicularity, maintaining tight mechanical tolerances, and preventing thermal distortion help achieve clean, vertical edges. By addressing these factors, manufacturers can significantly improve dimensional accuracy, reduce rework, and produce high-quality parts with consistent geometric precision.

Environmental Factors

Even when fiber laser cutting systems are well-maintained and properly calibrated, the surrounding operating environment can significantly influence cutting stability, component lifespan, and overall production quality. Fiber laser cutting machines rely on precise optical transmission, stable motion systems, and effective cooling, all of which can be disrupted by environmental changes. Temperature fluctuations, humidity levels, airborne dust, and contaminants in the workspace directly impact optical surfaces, electronics, sensors, and mechanical components. These external conditions often cause subtle performance degradation that accumulates over time—leading to inconsistent cuts, reduced machine precision, or unexpected faults. Understanding how environmental factors influence the cutting system is essential for ensuring long-term reliability and high-quality processing.

Temperature and Humidity Fluctuations

Causes

Temperature swings and improper humidity levels create thermal and mechanical instability in fiber laser cutting equipment. Excessive heat can cause expansion of machine frames, cutting heads, and optical mounts, leading to focus drift, misalignment, or fluctuations in beam shape. High temperatures also reduce cooling efficiency, placing additional stress on the laser source and power electronics. Conversely, low temperatures can thicken lubricants, impede motion system responsiveness, and affect the viscosity of coolant, reducing thermal control accuracy.

Humidity is equally critical. High humidity promotes moisture formation on optical lenses, protective windows, and electronic circuits, leading to fogging, corrosion, or short circuits. Condensation may occur during sudden temperature changes or when the machine is started in a cold environment. Low humidity increases static electricity, which can attract dust to optical components or increase the risk of electrostatic discharge damaging sensitive electronics.

Solutions

The most effective approach is to control the environmental conditions through stable temperature and humidity management. Maintaining the workspace within the machine’s recommended range—typically around 20–26℃ temperature and 40–60% humidity—ensures consistent thermal behavior. Installing air conditioning, dehumidifiers, or humidity control systems stabilizes the operating environment. Gradual warm-up cycles help prevent condensation when machines are started in cold conditions.

Ensuring proper coolant system maintenance—including checking water temperature, filtration, and flow rate—helps eliminate heat-induced instability in the laser source and optics. Keeping the machine in an insulated or climate-controlled room minimizes rapid thermal gradients. Regular inspection of optics for moisture or fogging ensures that temperature or humidity-related contamination is addressed before it impacts beam delivery.

Air Quality

Causes

Poor air quality in the workshop can introduce a variety of contaminants into sensitive components of the fiber laser cutting system. Dust, metal particles, fumes, oil mist, and smoke generated by cutting operations or nearby industrial processes can accumulate on protective windows, lenses, motion systems, and electronics. These particles degrade beam quality, block gas nozzles, or reduce the accuracy of sensors and encoders. Airborne oil mist from machining centers or lubricants may condense on optical surfaces and react with heat, creating stubborn residue. In extreme cases, contaminated air can enter the laser source’s internal pathways or cooling system, jeopardizing long-term performance.

Airborne slag and oxidation particles from the cutting process itself can also recirculate if ventilation or extraction systems are inadequate. Over time, this increases contamination levels inside the cutting head and shortens the life of the protective lens.

Solutions

Effective air quality management requires a combination of dust control, ventilation, and filtration. Installing high-efficiency air filtration systems or dust collectors near the cutting area prevents particles from entering the machine environment. Localized fume extraction systems remove smoke, vapor, and fine dust at the source, reducing airborne contamination. Maintaining cleanroom-grade air around the laser source—often achieved through sealed cabinets or controlled airflow—protects critical optical components.

Routine cleaning of the machine’s interior, along with frequent replacement of protective windows and filters, helps maintain optimal optical transmission. Keeping the workshop floor clean, avoiding grinding operations near the cutting machine, and isolating oily machinery reduce particulate exposure. For facilities with heavy cutting workloads, integrating a multi-stage ventilation system ensures that particles are continuously removed and do not settle on precision components.

Environmental factors such as temperature, humidity, and air quality play a major role in the stability and longevity of fiber laser cutting systems. Temperature and humidity fluctuations can cause focus drift, optical fogging, corrosion, or stress on mechanical and electrical components. These issues can be controlled through climate regulation, gradual warm-up routines, and stable cooling system maintenance. Poor air quality introduces dust, fumes, and oil mist that contaminate optics, disrupt sensors, and impair mechanical movement. Effective filtration, ventilation, and regular cleaning are essential to maintaining a clean operational environment. By proactively managing environmental conditions, manufacturers can significantly improve cutting consistency, extend machine lifespan, and reduce unexpected downtime.

Operator-Related Challenges

Even with advanced equipment, optimized parameters, and high-quality materials, the performance of fiber laser cutting systems ultimately depends on the skill, judgment, and consistency of the operator. Human factors remain one of the most significant contributors to cutting variability, especially in production environments where multiple shifts, varied experience levels, or high workloads can influence results. Operator-related challenges often manifest as improper parameter selection, inconsistent maintenance practices, inefficient task sequencing, or inadequate understanding of machine behavior. These issues directly impact cutting quality, uptime, consumable life, and overall productivity. Addressing operator-related deficiencies is essential not only for achieving technical accuracy but also for ensuring safe, efficient, and repeatable operation throughout the production process.

Lack of Training and Expertise

Causes

The complexity of modern fiber laser cutting systems means that inexperienced operators may struggle with parameter optimization, troubleshooting, or material-specific adjustments. Rapid advancements in laser technology—such as high-power fiber sources, autofocus cutting heads, and intelligent CNC controls—require continuous learning, but many operators rely on outdated knowledge or trial-and-error methods. Insufficient training leads to incorrect settings for power, speed, focus, and gas pressure, resulting in poor edge quality, excessive slag, failed piercings, or reduced cutting efficiency. Lack of understanding of nozzle selection, beam alignment, or lens maintenance further contributes to recurring problems. In high-turnover facilities, inconsistent operator skill levels amplify these issues, creating unpredictable cutting outcomes.

Solutions

Improving operator expertise begins with structured, standardized training programs. Comprehensive instruction should cover machine fundamentals, parameter selection, material behavior, maintenance routines, and troubleshooting techniques. Regular skill assessments help ensure that operators understand how to adjust cutting parameters, interpret cut quality, and respond to machine alarms or anomalies. Providing access to digital manuals, parameter libraries, and application guidelines helps operators make informed decisions. Training should also include hands-on maintenance practices, such as nozzle centering, protective lens changes, and cleaning procedures. Encouraging collaboration between operators, engineers, and equipment suppliers strengthens knowledge transfer and ensures ongoing skill development. Well-trained operators become proactive in identifying issues early, reducing downtime, and improving process stability.

Inefficient Workflow

Causes

Workflow inefficiencies often arise from poor production planning, disorganized workspaces, or inconsistent standard operating procedures (SOPs). Without clear-cut sequences, operators may repeatedly reposition materials, waste time loading and unloading sheets, or cause bottlenecks between processes. Inadequate nesting strategies or poor program preparation can lead to unnecessary head travel, excessive piercing, and longer cycle times. Lack of coordination between machine operations, material handling, and auxiliary tasks—such as part sorting, labeling, or deburring—further slows production. Inefficient workflows also increase operator fatigue, which contributes to mistakes and inconsistent performance.

Solutions

Optimizing workflow requires both organizational improvements and automation support. Implementing well-defined SOPs for material loading, cutting sequence setup, nozzle changes, and quality checks establishes consistency across shifts. Using advanced nesting software reduces head travel, minimizes scrap, and improves cutting efficiency. Organizing the workspace with clear layout zones for raw materials, finished parts, and accessories shortens handling time and prevents confusion. Introducing automation—such as material loading systems, conveyor sorting, or inline part tracking—boosts throughput and reduces operator workload. Clear scheduling and communication between production teams ensure that operators are not forced into reactive or unplanned tasks. Continuous process review and lean manufacturing principles help identify workflow bottlenecks and drive long-term efficiency improvements.

Operator-related challenges are among the most influential factors affecting fiber laser cutting quality and production efficiency. A lack of training can lead to incorrect parameter settings, inconsistent maintenance, and slow troubleshooting, resulting in poor cut quality and unnecessary downtime. Structured training programs, clear guidelines, and hands-on practice are essential for building operator competence. Inefficient workflow further reduces productivity through wasted motion, poor organization, and inconsistent procedures. Implementing standardized SOPs, optimizing nesting and scheduling, and improving workspace organization help create smoother, more efficient operations. By empowering operators with proper training and well-designed workflows, manufacturers can significantly increase cutting consistency, reduce errors, and maintain high levels of productivity across all shifts.

Preventive Measures and Best Practices

Addressing challenges in fiber laser cutting is not limited to solving issues after they occur; long-term productivity and consistent cut quality depend heavily on proactive measures. Preventive practices enable manufacturers to minimize downtime, extend equipment lifespan, reduce consumable costs, and ensure predictable cutting performance across materials and thicknesses. A strong prevention-oriented approach incorporates proper machine maintenance, systematic parameter optimization, skilled operators, and ongoing improvements in workflow and technology adoption. Implementing these best practices transforms laser cutting from a reactive process—where problems are fixed only after defects appear—into a stable, high-efficiency production system that delivers reliable results shift after shift.

Regular Machine Maintenance

Routine maintenance is the foundation of stable fiber laser cutting. Optical components such as protective windows, collimating lenses, and focusing lenses must be inspected frequently for contamination, scratches, or signs of thermal damage. Nozzles and ceramic rings should be replaced at the first sign of wear to maintain proper gas flow symmetry and prevent beam distortion. The motion system—including guide rails, rack-and-pinion drives, and bearings—requires regular lubrication and cleaning to avoid positional inaccuracies caused by friction or debris. Cooling systems must be monitored for water level, temperature consistency, and filter cleanliness, as temperature instability can directly affect beam quality. Scheduled checks of laser source condition, chiller performance, and cutting head alignment ensure long-term stability and prevent costly failures.

Parameter Optimization

Even the most advanced fiber laser cutting system depends on properly selected cutting parameters to ensure clean edges, minimal dross, and consistent kerf geometry. Power, speed, frequency, duty cycle, focus position, and gas pressure must be tuned to the material type, thickness, and surface condition. Creating standardized parameter libraries for common materials reduces operator error and shortens setup times. Advanced features such as dynamic focus control, multi-stage piercing programs, and intelligent auto-parameter systems can further stabilize cutting results. Periodically revisiting parameter sets—especially when switching to new materials, higher-power lasers, or upgraded cutting heads—is essential to maintaining optimal performance. Ensuring correct nesting, lead-in design, and cutting order also contributes to predictable thermal behavior and uniform edge quality.

Operator Training

Highly skilled operators are essential for interpreting cut quality, adjusting parameters, and responding effectively to machine feedback. Comprehensive training should cover machine operation, optical maintenance, troubleshooting, material behavior, safety procedures, and parameter logic. Operators must understand how power, focus, gas, and speed interact to produce different edge characteristics. Training should emphasize preventive actions such as cleaning optics, detecting early signs of mechanical wear, and verifying nozzle alignment. Regular skill refreshers and cross-training allow teams to share best practices, reducing performance gaps between shifts. Well-trained operators not only reduce downtime and scrap but also elevate the overall consistency and efficiency of the cutting process.

Continuous Improvement

A culture of continuous improvement ensures that fiber laser cutting performance evolves with changing production demands. Regular audits of cut quality, consumable usage, and machine uptime help identify inefficiencies or emerging problems. Implementing lean manufacturing practices—such as reducing unnecessary machine movement, optimizing material flow, or improving workstation layout—can significantly enhance throughput. Data-driven monitoring systems and cutting-edge analytics provide real-time insight into machine performance, helping predict maintenance needs or identify parameter drift. Collaboration with machine manufacturers, laser experts, and application engineers ensures that the cutting process benefits from new techniques, updated software features, and more advanced consumables. Documenting lessons learned and updating SOPs ensures that improvements become standardized practice rather than temporary fixes.

Preventive measures and best practices are essential to maintaining stable, high-quality fiber laser cutting. Regular machine maintenance keeps optical and mechanical components performing reliably, reducing unexpected downtime. Parameter optimization ensures clean, consistent cuts across materials and thicknesses. Operator training empowers personnel to make informed decisions, perform effective maintenance, and respond quickly to issues. Continuous improvement allows manufacturers to refine processes, integrate new technologies, and identify inefficiencies early. When combined, these proactive strategies create a robust, predictable, and highly efficient fiber laser cutting environment that minimizes errors, boosts productivity, and maximizes long-term equipment value.

Summary

Fiber laser cutting has become a cornerstone of modern metal fabrication, offering unmatched speed, precision, and flexibility. Yet, like any advanced manufacturing process, it presents a series of challenges that must be proactively understood and managed to ensure consistent, high-quality results. Material-related factors such as reflectivity, thermal conductivity, warpage, and thickness variations influence how effectively the laser interacts with the workpiece. Cutting-quality issues—including edge roughness, burr formation, taper, and angular deviation—often arise from improper parameters, unstable beam transmission, or insufficient gas dynamics. Machine-related problems such as optical contamination, mechanical wear, and alignment drift further complicate the process if not addressed with timely maintenance and calibration.

Environmental conditions, including temperature, humidity, and air quality, also play a critical role in system stability, while operator knowledge and workflow efficiency directly impact day-to-day performance. Preventive measures—such as structured maintenance routines, parameter optimization, operator training, and continuous improvement programs—are essential to overcoming these obstacles.

By understanding the root causes of common fiber laser cutting problems and implementing targeted solutions and best practices, manufacturers can significantly enhance cut quality, reduce downtime, and maximize overall productivity. A proactive, well-informed approach ensures that fiber laser cutting systems operate at their full potential, delivering reliable and repeatable results across diverse applications.

Get Laser Cutting Solutions

As fiber laser cutting applications continue to expand across industries, having a reliable technology partner is essential for maintaining high productivity and consistent quality. Maxcool CNC, a leading manufacturer of intelligent laser equipment, provides comprehensive solutions designed to address the full spectrum of cutting challenges faced in modern fabrication environments. From high-precision fiber laser cutting machines to advanced automation systems and smart process-control technologies, Maxcool CNC delivers equipment engineered for stability, efficiency, and long-term durability.

Maxcool CNC’s application engineers work closely with manufacturers to diagnose cutting issues such as slag formation, edge burrs, piercing failures, taper, and material-related inconsistencies. By analyzing process parameters, material conditions, and machine performance, they develop customized cutting strategies that optimize power settings, focus control, gas selection, and cutting paths. Maxcool CNC also offers operator training, maintenance guidance, and real-time technical support to ensure every system runs at peak performance.

With expertise spanning laser sources, motion systems, intelligent sensors, and automation integration, Maxcool CNC empowers customers to overcome common fiber laser cutting challenges and achieve superior results across a wide range of materials and thicknesses. Whether upgrading existing workflows or establishing new production lines, Maxcool CNC provides reliable, high-efficiency laser cutting solutions tailored to your specific manufacturing needs.